Discover the Benefits of Wood Plastic Composite Panels for Construction

Wood plastic composite panels have gained significant attention in the construction industry due to their unique combination of properties that make them an excellent alternative to traditional materials. These panels are manufactured through a specific process that combines wood fibers with thermoplastics, resulting in a versatile and durable product. This article will explore the benefits of wood plastic composite panels from a materials production technology perspective.

The production of wood plastic composite panels begins with the careful selection of raw materials. The wood fibers used in these panels can come from various sources, including recycled wood waste and virgin wood. This not only helps in reducing environmental impact by utilizing waste materials but also ensures that the wood used is of high quality. The choice of thermoplastics, such as polyethylene or polypropylene, is equally important. These plastics are chosen for their durability, resistance to moisture, and ability to be recycled, further enhancing the sustainability of the final product.

Once the raw materials are selected, they undergo a series of processing steps. The first step is the compounding of wood fibers and thermoplastics. In this phase, the wood fibers are mixed with the plastic matrix, often using a twin-screw extruder. This equipment allows for precise control over the mixing process, ensuring that the wood and plastic are evenly distributed. The extruder also applies heat and shear, which helps to melt the plastic and bond it with the wood fibers. This step is crucial because it determines the mechanical properties of the final composite material.

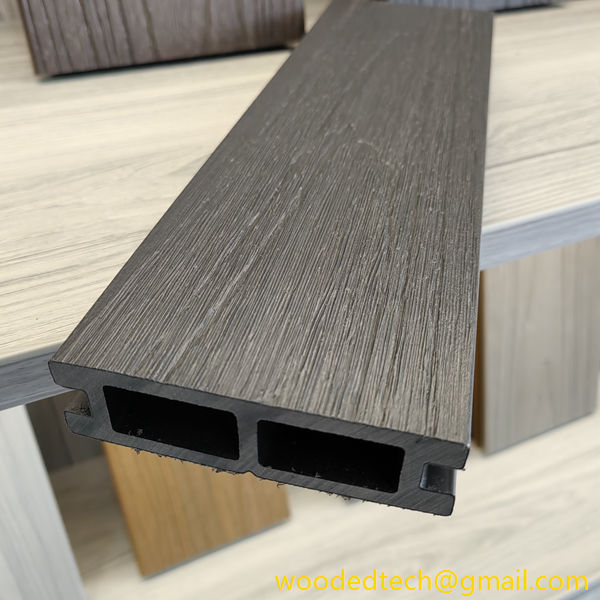

After compounding, the mixture is cooled and pelletized to create small granules that can be easily handled and transported. These pellets can then be fed into a molding machine, where they are heated and pressed into panels of various shapes and sizes. This step allows for versatility in design, as the panels can be produced in different thicknesses and surface finishes to meet specific project requirements.

One of the key benefits of wood plastic composite panels is their outstanding durability. The combination of wood and plastic results in a material that is resistant to rot, moisture, and insects, which are common problems faced by traditional wood products. This durability extends the lifespan of the panels, making them a cost-effective choice for construction projects. Additionally, the resistance to weathering means that these panels can be used in a variety of applications, both indoors and outdoors, without significant degradation over time.

Another significant advantage is the low maintenance requirement of wood plastic composite panels. Unlike traditional wood, which often needs regular painting, staining, or sealing, composite panels require minimal upkeep. A simple wash with soap and water is generally sufficient to keep them looking new. This ease of maintenance not only saves time and labor costs but also allows for a more sustainable approach to building maintenance.

In terms of aesthetic appeal, wood plastic composite panels can be designed to mimic the look of natural wood while offering the benefits of modern materials. They can be produced in a wide range of colors and finishes, allowing architects and designers to create visually appealing structures that fit seamlessly into various environments. This versatility in design makes them an attractive option for both residential and commercial construction.

From an environmental perspective, the use of wood plastic composite panels is a forward-thinking choice. The incorporation of recycled materials in their production process significantly reduces waste and conserves natural resources. Additionally, since they are recyclable at the end of their life cycle, they contribute to a circular economy. This sustainability aspect is increasingly important to consumers and builders who are looking for eco-friendly construction options.

Moreover, the production process of wood plastic composite panels is becoming more efficient and less energy-intensive over time. Advances in technology have led to the development of more effective manufacturing techniques that reduce energy consumption and minimize waste. These improvements not only enhance the sustainability of the panels but also make them more competitive in terms of pricing.

In conclusion, wood plastic composite panels offer numerous benefits for construction projects, particularly from a materials production technology perspective. Their durability, low maintenance requirements, aesthetic versatility, and sustainability make them an attractive alternative to traditional building materials. As manufacturing processes continue to evolve, it is likely that the use of wood plastic composite panels will become even more prevalent in the construction industry, paving the way for a more sustainable future. By embracing these innovative materials, builders and architects can contribute to a greener environment while delivering high-quality, long-lasting structures.