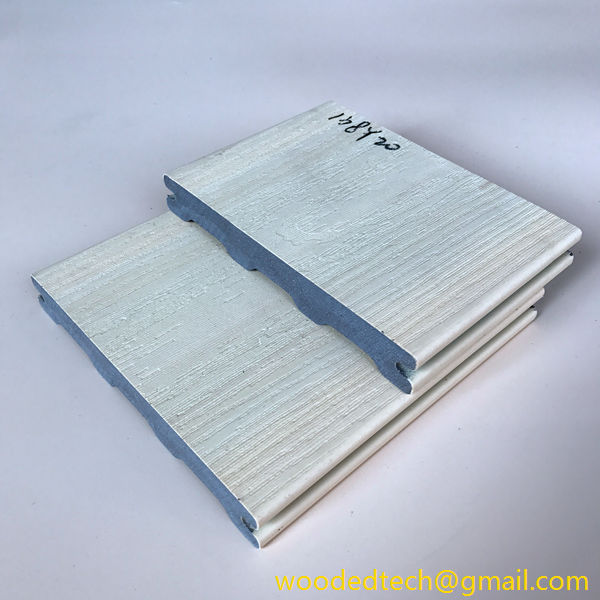

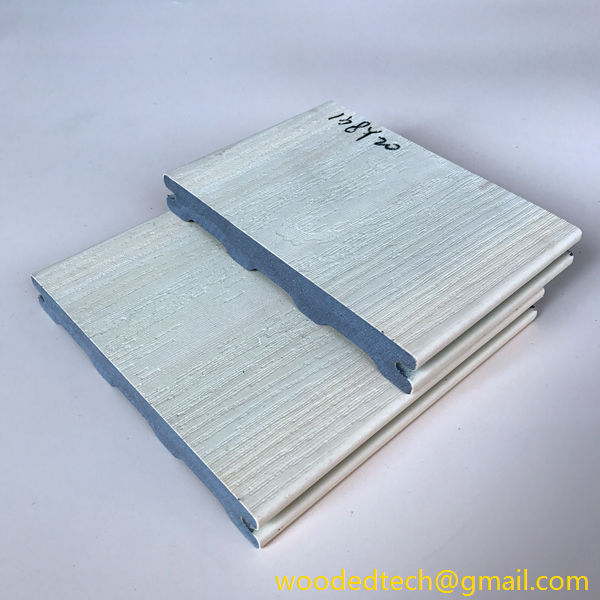

Title: Outdoor wpc panel white: the challenge of purity and durability

Teks:

When we talk about outdoor building materials, wpc panel white always attracts people’s attention. Its natural texture, simple color, and harmonious integration with the environment make this material popular in the field of outdoor construction and decoration. However, the color problem of outdoor wpc panel white has always attracted much attention: its color is easy to be dirty, and the production difficulty is relatively high. Today, we will explore this topic in depth, explore the reasons behind it, and share some solutions.

1. Color characteristics of outdoor wpc panel white

White, as a bright and pure color, always gives people a fresh and natural feeling. However, in outdoor environments, the color of wpc panel white is easy to be dirty. This is because white has a high contrast with dust and dirt, and once the surface is stained, it will be particularly obvious. In addition, the outdoor environment is complex and changeable, and the board must also face the test of natural factors such as ultraviolet radiation and rain erosion, which puts higher requirements on its color maintenance.

2. Reasons for high production difficulty

The production difficulty of wpc panel white is relatively high, mainly due to the strict requirements of its raw materials and processes. First of all, the selection of raw materials is very important. High-quality wood and plastic are the basis for ensuring the quality of the board. In addition, the production process is also crucial. During the production process, temperature, pressure and time need to be precisely controlled to ensure the density, strength and durability of the board. At the same time, in order to meet the color requirements of wpc panel white, special surface treatment is required, which increases the complexity and difficulty of the production process.

3. Solutions and coping strategies

1. Select high-quality raw materials: In order to produce high-quality outdoor wpc panel white, we must first start with raw materials. Selecting high-quality wood and plastic can ensure the basic quality of the board, thereby extending its service life and maintaining the color.

2. Improve the production process: Improve production efficiency and product quality by improving the production process. For example, use advanced production equipment and technology to optimize the production process to ensure the uniformity and density of the board.

3. Special surface treatment: In view of the problem that wpc panel white is easy to be dirty, a special surface treatment process can be used. For example, use anti-ultraviolet agents, waterproof agents, etc. to improve the durability and stain resistance of the board.

4. Regular cleaning and maintenance: For the installed wpc panel white, regular cleaning and maintenance are also very important. You can use professional cleaners and maintenance agents to remove stains and dirt on the surface to keep the board clean and beautiful.

5. Reasonable planning and design: In outdoor construction and decoration, reasonable planning and design are also the key to reducing the difficulty of wpc panel white maintenance. For example, install the board in a relatively clean area to avoid pollution, or use other colors to reduce the maintenance pressure of wpc panel white.

In short, although outdoor wpc panel white faces the challenges of color resistance and high production difficulty, we can overcome these difficulties by selecting high-quality raw materials, improving production processes, special surface treatment, regular cleaning and maintenance, and reasonable planning and design, so that this material can play a greater role in the field of outdoor construction and decoration. Let us look forward to the future development of outdoor wpc panel white and bring more purity and beauty to the outdoor environment.

13. Solutions to the problem that the color of outdoor wpc panel white is not resistant to dirt

For the problem that the color of outdoor wpc panel white is not resistant to dirt, the following solutions can be considered:

1. Choose materials with better anti-fouling performance: Develop new wood-plastic composite materials to improve the anti-fouling performance of the surface and make it more resistant to dirt.

2. Use surface treatment technology: Special treatment of the surface of the wood-plastic board, such as spraying anti-fouling agent, adding waterproof coating, etc., to improve the stain resistance of the board.

3. Regular cleaning and maintenance: Clean the outdoor wood-plastic board regularly to remove stains and accumulated dust to maintain its original color and beauty.

4. Choose other colors: Considering the easy-to-dirty nature of white, you can choose other colors of wood-plastic boards, such as gray, dark colors, etc., which are relatively more resistant to dirt.

14. Production difficulties and solutions

There are indeed some difficulties in the production of outdoor wpc panel white, such as color regulation, material mixing uniformity, production process control, etc. In response to these difficulties, the following solutions can be adopted:

1. Fine color control technology: Use professional color control technology to ensure the stability and consistency of the color of wood-plastic panels.

2. Optimize material mixing process: Improve material mixing equipment to ensure that various raw materials can be fully mixed and evenly mixed to improve product quality.

3. Strict production process control: Formulate strict production process parameters, accurately control each link in the production process, and ensure product quality and performance.

4. Introduce automated production lines: Use automated production lines to improve production efficiency, reduce production costs, and ensure product quality and stability.

15. Conclusion

In general, outdoor wpc panel white, as an emerging outdoor flooring material, has many advantages, such as environmental protection, durability, and beauty. Although there are some challenges, such as color resistance to dirt and production difficulties, these problems can be solved through technological progress and continuous innovation. In the future, with people’s pursuit of outdoor lifestyles and the increasing demand for environmentally friendly materials, the market prospects of WPC terrace decks and outdoor wpc panel white will be very broad.