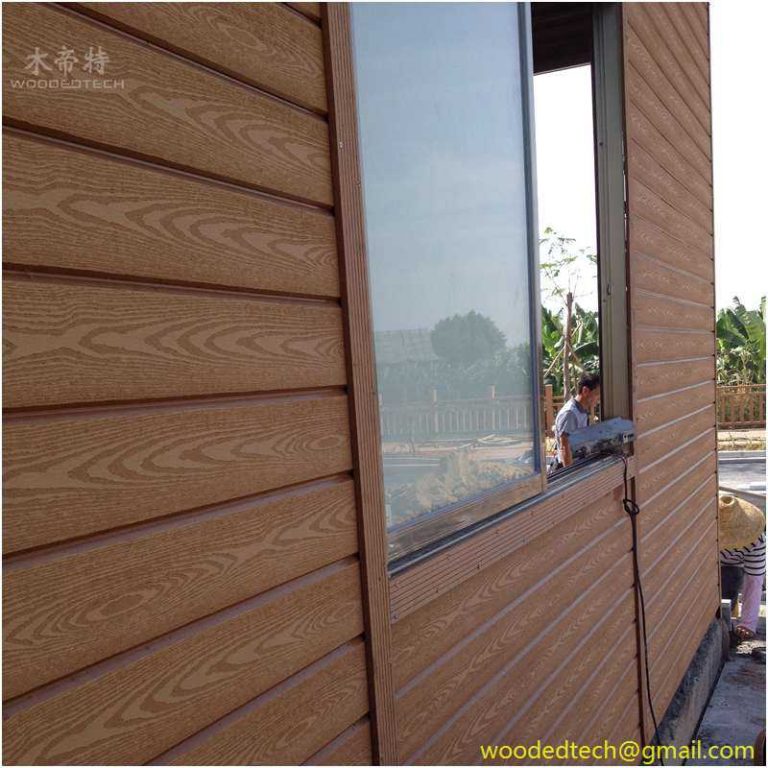

The use of pannello wpc materials has become a trend in outdoor decoration projects. .

Especially companies like sumuchang.com focus on outdoor wood plastic projects and provide one-stop solutions, including plastic wood pavilions, grape racks, railings, etc. .

However, during the construction process, how to open holes and seal the pannello wpc is a technical job, especially when adjustments need to be made on site. .

Let’s take a look at why it is so important to process outdoor wpc panels. .

Wpc panels combine the beauty of wood and the durability of plastic, but at the same time they also bring new challenges.

For example, when making mortise and tenon connections, it is necessary to ensure that the mortise and tenon are perfectly matched with the handrail, which is not only related to beauty, but also to the stability of the structure. .

If the mortise and tenon are not done well, it may result in a loose joint, affecting the overall service life and safety.

How to deal with this problem? Traditionally, carpenters use handheld tools for manual operation. Although this method is flexible, it has very high technical requirements for operators and is not efficient.

Sumuchang.com uses a mechanized method, using a precision engraving machine for tenon processing, and through computer program control, it not only improves efficiency but also ensures processing accuracy. .

For large-scale production, this is undoubtedly a better choice.

However, in actual projects, especially on-site construction, the conditions are often relatively simple, which requires carpenters to make manual adjustments based on experience and on-site conditions.

In this case, although the efficiency is lower, it can better adapt to the complex and changing actual needs.

In addition to tenon processing, sumuchang.com is also good at other difficult pannello wpc product processing, such as bending projects, large-span projects, etc. .

These projects often require higher technical levels and innovation capabilities.

For example, when making curved plastic wood beams, not only the curvature must be accurately calculated, but also the load-bearing and stability of the structure must be considered. .

Through professional design and fine processing, sumuchang.com can ensure that every project can achieve the desired effect.

It is worth mentioning that the service tenet of sumuchang.com is “better to do fine, not greedy”.

They believe that only with concentration and care can a truly boutique project be created.

This concept is not only reflected in their choice of materials and processes, but also in their responsible attitude towards customers.

Whether it is the early design planning, the later construction and installation, or even the quality assurance service, sumuchang.com strives to do its best.

Whether it is mass production within the factory or individual adjustments at the construction site, sumuchang.com can provide professional and reliable solutions.

From manual to mechanized, to flexible processing on site, each method has its own unique features.

As a consumer or contractor, understanding these different processing methods can help us better choose the right service provider to ensure the smooth progress of the project.