In the wave of science and technology, co extrusion technology is like a rising star, injecting new vitality into modern industry.

Co extrusion technology extrudes two or more different materials at the same time to form a composite material, which not only improves the performance of the material, but also greatly reduces the cost.

Imagine that the exterior wall insulation in the construction industry, the lightweight components in automobile manufacturing, and even the key components of aerospace vehicles have benefited from the innovation and application of this technology.

The core of co extrusion technology lies in its delicate operation process and deep understanding of materials.

By precisely controlling the extrusion rate and proportion of different materials, composite materials with excellent performance can be created to meet the needs of specific fields.

For example, in the construction industry, composite materials made by co extrusion technology not only have good thermal insulation performance, but also enhance the strength of the wall and extend the service life of the building.

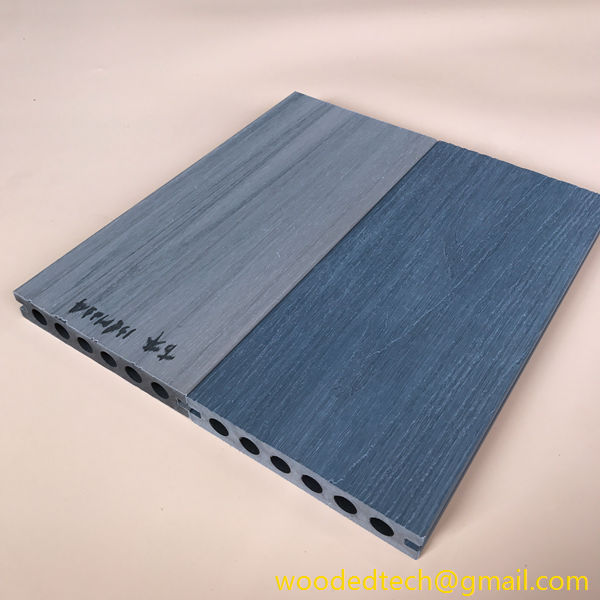

For example, in the outdoor floor and wall panel industry, co extrusion WPC decking and co extrusion WPC wall panel made by co extrusion technology have excellent weather resistance, beautiful appearance, and extremely high cost performance, and quickly became popular all over the world.

With the continuous advancement of science and technology, the application areas of co extrusion technology are constantly expanding.

From small objects in daily life to high-end industrial products, its influence is gradually penetrating into every corner of our lives.

Understanding co extrusion technology can not only make us better understand the charm of modern technology, but also inspire our passion for exploring the infinite possibilities behind technological progress.