The truth about the split of inferior outdoor composite decking: quality determines service life!

Introduction: As an emerging environmentally friendly material, outdoor composite decking has become more and more popular among consumers in recent years. However, there are endless inferior composite deckings on the market, causing many consumers to encounter problems such as cracking during use. This article will analyze in detail the reasons why inferior outdoor composite decking splits, as well as how to identify and choose high-quality composite decking.

1. Why does inferior outdoor composite decking crack?

1. Unreasonable material formula: In order to reduce costs, manufacturers of inferior composite decking often use unqualified raw materials, such as waste plastics and inferior wood powder. The quality of these raw materials is unstable, which makes the floor easy to crack during use.

2. Rough production process: The production process of inferior composite decking is relatively simple, and the equipment is backward, which cannot guarantee the density and strength of the floor. In outdoor environments, the floor is easily affected by factors such as temperature and humidity, resulting in cracking.

3. Poor waterproof performance: Outdoor composite decking needs to have good waterproof performance. Poor quality flooring has poor waterproof performance. Rainwater entering the floor will cause the floor to expand and deform, and then cause cracking.

4. Poor weather resistance: Outdoor composite decking needs to have a certain degree of weather resistance to adapt to various harsh climate conditions. Poor quality flooring has poor weather resistance and is prone to cracking in high and low temperature environments.

2. How to identify poor quality outdoor composite decking?

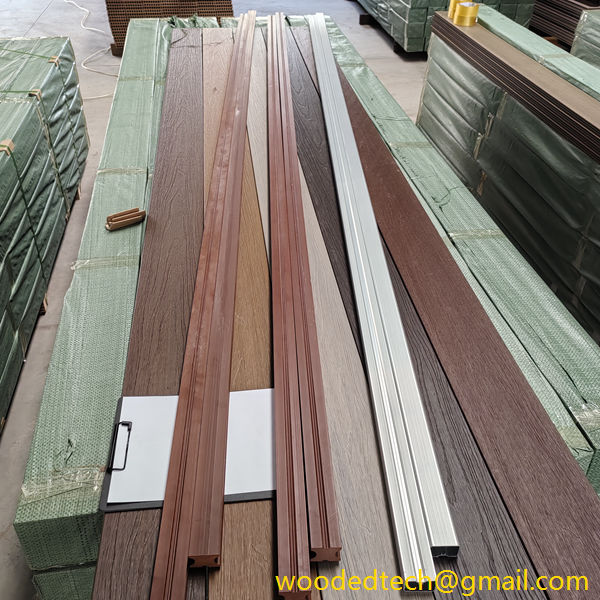

1. Observe the appearance: High-quality composite decking has a smooth, flat surface and uniform color. Poor quality flooring has a rough surface, uneven color, and even obvious scratches and bubbles.

2. Check the density: High-quality composite decking has a higher density and feels heavy. Poor quality flooring has a lower density and feels lighter.

3. Smell: High-quality composite decking has no irritating odor, while poor quality flooring has an obvious plastic smell or odor.

4. Check the certification: When purchasing composite decking, check whether there are relevant environmental protection and quality certifications, such as ISO9001, ISO14001, etc.

3. How to choose high-quality outdoor composite decking?

1. Choose a regular manufacturer: When buying outdoor composite decking, choose products from regular manufacturers with a good reputation.

2. Pay attention to quality: High-quality composite decking has high requirements in terms of raw materials, production process, waterproof performance, etc. Consumers should pay attention to quality when purchasing.

3. Tailor-made: According to actual needs, choose the appropriate floor specifications, colors and styles.

4. Understand after-sales service: When buying composite decking, understand the after-sales service policy, such as warranty period, maintenance service, etc.

Summary:

Poor-quality outdoor composite decking will indeed crack, causing many troubles for consumers. In order to avoid this problem, consumers should pay attention to quality when purchasing and choose high-quality composite decking produced by regular manufacturers. At the same time, understanding the relevant knowledge of composite decking and improving the ability to distinguish can ensure the service life and beauty of outdoor composite decking.