Difference in composite decking

Exploring similarities and differences: Difference analysis of outdoor composite decking from different manufacturers

With the improvement of environmental awareness and the development of science and technology, outdoor composite decking, as a new environmentally friendly building material, is becoming more and more popular among consumers. However, there are many brands of outdoor composite decking on the market, and there are certain differences in performance, appearance, price and other aspects of the floors produced by different manufacturers. This article will conduct a detailed analysis of the differences between outdoor composite decking from different manufacturers to help consumers better choose the products that suit them.

I. Introduction to outdoor composite decking

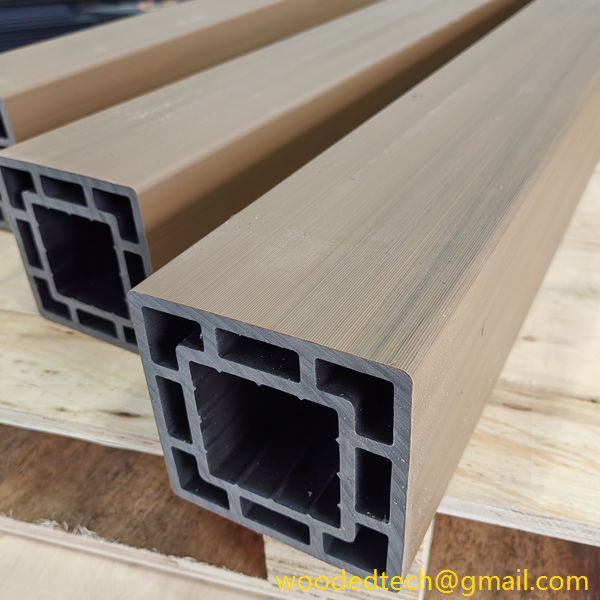

Outdoor composite decking is a new type of composite material made of a mixture of wood powder and plastic. It has the natural texture of wood and the waterproof and anti-corrosion properties of plastic. It not only retains the natural texture and color of wood, but also overcomes the shortcomings of wood being easy to corrode and deform, making it an ideal outdoor floor decoration material.

II. Difference analysis of outdoor composite decking from different manufacturers

1. Raw materials and production process

(1) Raw materials

There are certain differences in the raw materials used by different manufacturers to produce outdoor composite decking. Generally speaking, high-quality raw materials mainly include wood powder, plastic and additives. The quality of wood powder directly affects the texture and feel of the floor. High-quality wood powder particles are fine and uniform. The quality of plastic is related to the waterproof and anti-corrosion properties of the floor. High-quality plastic has good weather resistance. Additives are the key to ensuring the performance of the floor. High-quality additives can make the floor have better anti-aging and anti-ultraviolet properties.

(2) Production process

The production processes adopted by different manufacturers to produce outdoor composite decking are also different. At present, the main production processes on the market include high-temperature pressing, low-temperature pressing and co-extrusion. High-temperature pressing can make the floor have higher density and strength, low-temperature pressing can ensure that the floor has good flexibility and impact resistance, and co-extrusion can achieve special textures and colors on the surface of the floor. When choosing, consumers can choose the appropriate production process according to their needs.

2. Performance indicators

The performance indicators of outdoor composite decking mainly include waterproof, anti-corrosion, anti-aging, anti-ultraviolet, wear resistance, etc. There are certain differences in these performance indicators between floors produced by different manufacturers. The following are some common performance indicator comparisons:

(1) Waterproofness

High-quality outdoor composite decking has good waterproof performance and can be immersed in water for a long time without deformation or expansion. This is because high-quality flooring uses plastics and additives with good waterproof properties.

(2) Anti-corrosion

High-quality outdoor composite decking has good anti-corrosion properties and can effectively prevent the growth of microorganisms such as bacteria and fungi. This is because high-quality flooring uses plastics and additives with good anti-corrosion properties.

(3) Anti-aging

Outdoor composite decking is easily affected by factors such as ultraviolet rays and rain during long-term use, which leads to aging. High-quality flooring has good anti-aging properties, which can ensure that the floor will not fade or deform after long-term use.

(4) Anti-ultraviolet performance

Outdoor composite decking is easily affected by ultraviolet rays under sunlight, which leads to fading and aging. High-quality flooring has good anti-ultraviolet performance and can effectively resist the damage of ultraviolet rays.

3. Appearance design

Outdoor composite decking produced by different manufacturers also has different appearance designs. The following are some common appearance design differences:

(1) Color

Outdoor composite decking has a variety of colors, and the colors of floors produced by different manufacturers are slightly different. Consumers can choose the appropriate floor color according to their preferences and needs.

(2) Texture

Outdoor composite decking has a variety of textures, and the textures of floors produced by different manufacturers are also different. Consumers can choose the appropriate floor texture according to their aesthetic needs.

(3) Size

Outdoor composite decking has a variety of sizes, and the sizes of floors produced by different manufacturers are slightly different. When purchasing, consumers can choose the appropriate floor size according to their actual needs.

4. Price

Outdoor composite decking produced by different manufacturers also has certain differences in price. Generally speaking, the price of high-quality flooring is relatively high, but the performance and service life are also relatively long. When purchasing, consumers can choose the appropriate flooring according to their budget and needs.

III. Summary

In short, outdoor composite decking produced by different manufacturers has certain differences in raw materials, production processes, performance indicators, appearance design, etc. Consumers should consider these factors comprehensively when purchasing and choose products that suit them. At the same time, consumers should also pay attention to the environmental performance of the floor, choose high-quality flooring that meets national environmental standards, and contribute to our living environment.