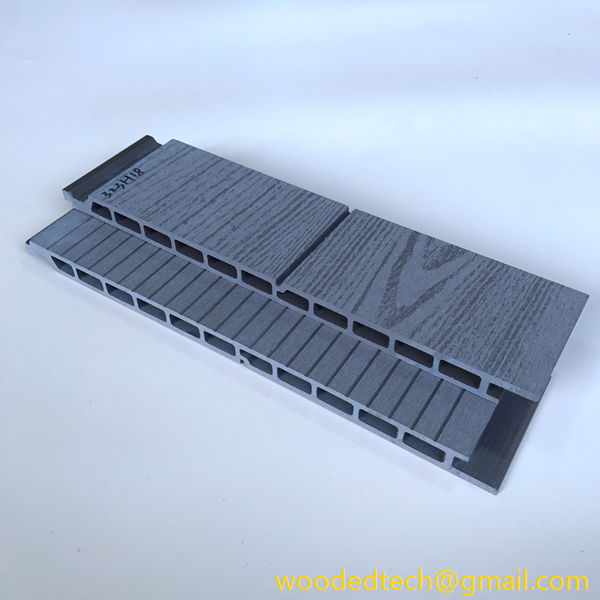

Analysis of the factors limiting the width of outdoor WPC Board: production process, installation and durability considerations

As an emerging environmentally friendly building material, outdoor WPC Board has gradually become the preferred material for outdoor decoration and landscape construction with its excellent performance and beautiful appearance. However, in the actual production and application process, the width of outdoor WPC Board is often not too large. This article will analyze in detail the factors affecting the width of outdoor WPC Board from the aspects of production extrusion process, installation and durability.

1. The influence of production extrusion process on the width of outdoor WPC Board

1. Extruder performance limitation

The width of outdoor WPC Board is limited by the performance of the extruder. During the extrusion process, the pressure, temperature and shear force of the material in the extruder determine the width of the WPC Board. Generally speaking, the better the performance of the extruder, the more stable the flow of the material in the barrel, and the larger the width of the WPC Board that can be produced.

2. Die design limitation

The die is the key factor in determining the width of the outdoor WPC Board. The width of the die determines the width of the WPC Board. When designing the mold, the strength, rigidity and stability of the mold should be considered to ensure that deformation, cracking and other problems will not occur during the production process. In addition, the design of the mold also needs to consider production efficiency and cost to achieve mass production.

3. Material property restrictions

The raw materials for the production of outdoor WPC Board mainly include plastics, wood powder and additives. The properties of these materials have a certain impact on the width of the WPC Board. For example, parameters such as the particle size, water content of wood powder and the melt index of plastic will affect the fluidity of the material, and then affect the width of the WPC Board.

2. The impact of installation factors on the width of outdoor WPC Board

1. Installation method restrictions

The installation method of outdoor WPC Board will also affect its width. Common installation methods include splicing, snap-on and fixed. The splicing and snap-on installation methods have lower requirements for the width of the WPC Board, while the fixed installation requires a smaller width of the WPC Board to ensure a firm installation.

2. Structural design restrictions

During the installation process of outdoor WPC Board, it is necessary to consider its coordination with the building structure. A WPC Board that is too wide may affect the overall beauty and structural stability of the building. Therefore, when designing the width of the WPC Board, the structural characteristics of the building should be fully considered.

III. The impact of durability on the width of the outdoor WPC Board

1. Anti-aging performance

Outdoor WPC Boards need to have good anti-aging performance in outdoor environments. WPC Boards that are too wide are prone to aging and cracking under the influence of external factors such as ultraviolet rays and rain. Therefore, in order to ensure the durability of the WPC Board, its width should not be too large.

2. Weather resistance

Outdoor WPC Boards need to maintain stable performance in harsh environments such as cold and high temperatures. WPC Boards that are too wide are prone to deformation and cracking in environments with large temperature differences. Therefore, when designing the width of the WPC Board, its weather resistance should be considered.

In summary, the width of the outdoor WPC Board will not be too large, mainly affected by factors such as production extrusion process, installation and durability. In the actual production and application process, the width of the WPC Board should be reasonably determined according to the specific situation to ensure its performance and beauty.

Summary:

As a green and environmentally friendly building material, outdoor WPC Board has been widely used in my country. While pursuing beauty and practicality, we also need to pay attention to issues such as its production, installation and durability. By reasonably determining the width of outdoor WPC Board, it can perform better in outdoor environments and contribute to my country’s green building cause.