Continuous production of wpc sheet flooring: an innovative way to create high-quality floors with uniform cross-sections

With the rapid development of my country’s economy, the construction industry has an increasing demand for new building materials that are environmentally friendly, beautiful and durable. As an emerging green and environmentally friendly building material, wpc sheet flooring has won the favor of the market with its excellent performance and beautiful appearance. This article will introduce in detail the continuous production process of wpc sheet flooring and how to use advanced equipment to achieve the production of high-quality floors with uniform cross-sections.

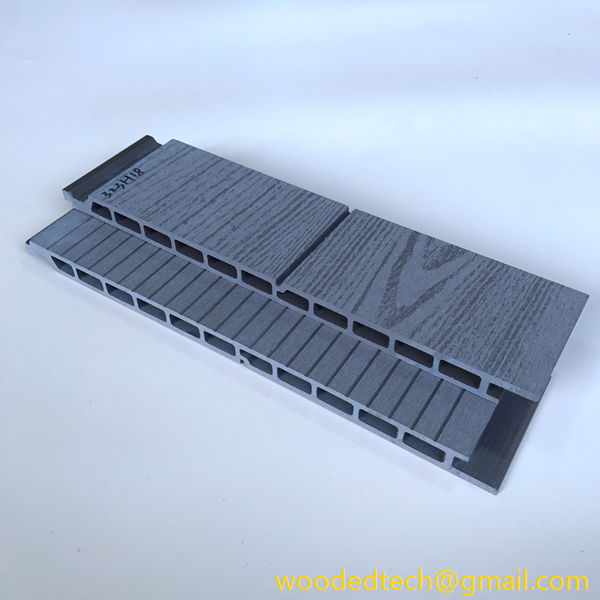

1. Introduction to wpc sheet flooring

wpc sheet flooring is a new type of composite material made of a mixture of wood powder and plastic. It has both the natural texture and beauty of wood and the waterproof, moisture-proof and corrosion-resistant properties of plastic. In addition, plastic floor profiles also have good wear resistance, anti-slip and anti-aging properties, long service life, and are widely used in indoor and outdoor floor decoration, garden landscape and other fields.

2. Continuous production equipment extrusion production line

In order to improve the production efficiency of wpc sheet flooring and reduce production costs, my country has adopted a continuous production equipment extrusion production line for molding production. The production line mainly consists of the following parts:

1. Extruder: heat and melt the mixture of wood powder and plastic, and extrude it through the extruder head.

2. Mold: according to the design requirements, extrude the molten material through the mold into the required cross-sectional shape.

3. Cooling device: cool the extruded profile to solidify it.

4. Cutting device: cut the cooled profile into the required length.

5. Quality inspection device: perform quality inspection on the produced profile to ensure that it meets the standard requirements.

3. Production of high-quality flooring with uniform cross-section

The use of continuous production equipment extrusion production line for molding production has the following advantages:

1. High efficiency: The continuous production line can realize automated production and improve production efficiency.

2. High quality: The mold has high precision to ensure the uniform cross-section of the profile and stable size.

3. Low energy consumption: The production line uses energy-saving equipment to reduce production costs.

4. Environmental protection: There is no wastewater or exhaust gas emission during the production process, which meets environmental protection requirements.

To achieve the production of uniform cross-section flooring, the following measures are essential:

1. Strict raw material selection: Select high-quality wood powder and plastic raw materials to ensure the intrinsic quality of the flooring.

2. Optimize formula design: According to market demand and raw material characteristics, optimize formula design to improve comprehensive performance.

3. Accurate mold design: According to floor design requirements, accurately design molds to ensure the uniformity of profile cross-section.

4. Strengthen quality control: Strictly monitor the key links on the production line to ensure the stable quality of the produced profiles.

5. Train skilled operators: Improve the skill level of operators to ensure the normal operation of the production line.

In short, the use of continuous production equipment extrusion production line for molding production can efficiently produce high-quality wpc sheet flooring with uniform cross-section. This is not only conducive to improving the development level of my country’s construction industry, but also to meet market demand and provide consumers with green, environmentally friendly, beautiful and durable floor decoration materials. In the future production process, we still need to continue to explore innovation, improve production technology, and contribute to the promotion of green development of my country’s construction industry.