Understanding What Composite Deck Boards Are Made Of for Quality Assurance

Composite deck boards have become increasingly popular in recent years, particularly among homeowners seeking low-maintenance, durable outdoor solutions. Understanding what these boards are made of is essential for quality assurance, as it directly impacts the performance, longevity, and overall aesthetic appeal of the decking. In this article, we will explore the composition of composite deck boards, their advantages, and how their materials contribute to quality assurance in the market.

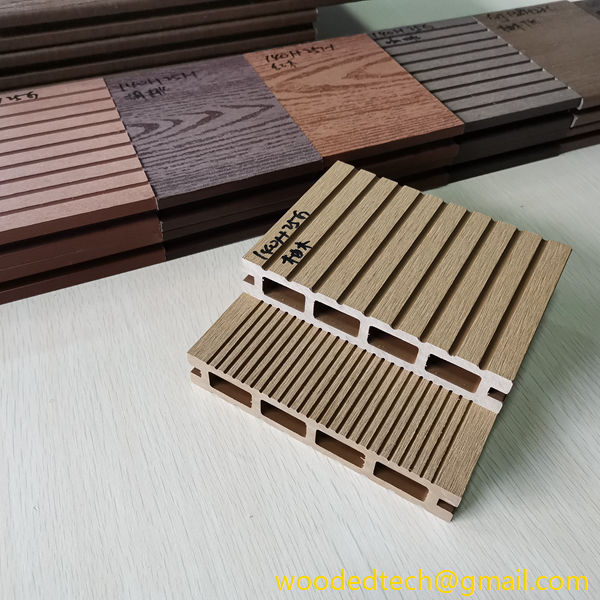

Composite deck boards are primarily made from a combination of wood fibers and plastic. This blend creates a material that not only mimics the look of natural wood but also offers enhanced durability and resistance to various environmental factors. The wood fibers used in composite decking often come from recycled materials, such as sawdust or wood shavings, making it an eco-friendly alternative to traditional wood decking. The plastic component usually consists of recycled polyethylene or polyvinyl chloride, which helps to protect the wood fibers from moisture, mold, and mildew.

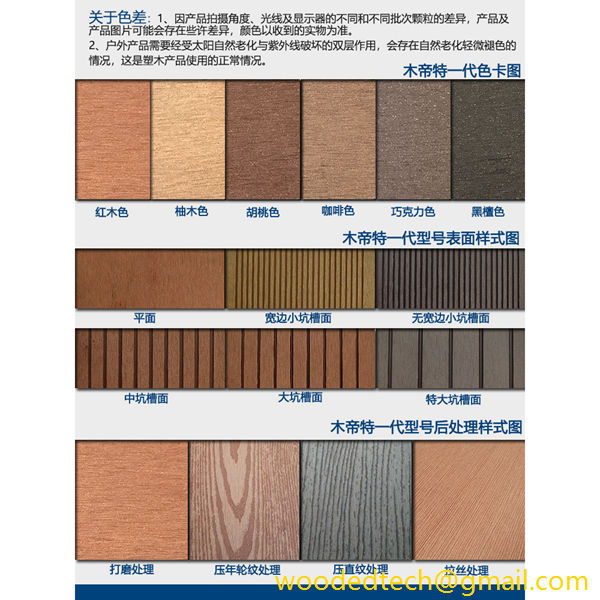

One of the significant advantages of composite deck boards is their resistance to fading and staining. Unlike traditional wood, which can be susceptible to sun damage and spills, composite materials are designed to withstand the elements. The manufacturing process often includes adding UV inhibitors to the plastic component, ensuring that the color remains vibrant over time. This is particularly important for homeowners who want a beautiful outdoor space without the need for constant maintenance.

Another factor contributing to the quality assurance of composite deck boards is their ability to resist warping and splintering. Traditional wood decking can be prone to these issues due to changes in temperature and humidity. Composite materials, however, are engineered to maintain their shape and structural integrity, providing a safe and comfortable surface for walking and lounging. This resistance to physical deformation is a vital aspect of quality assurance, as it ensures that the decking will perform well over time.

The manufacturing process of composite deck boards also plays a crucial role in their overall quality. Most reputable manufacturers employ advanced technology and strict quality control measures to ensure that their products meet or exceed industry standards. For example, some companies utilize a co-extrusion process that creates a protective shell around the core of the board. This outer layer adds an extra level of protection against scratches, stains, and fading, further enhancing the board’s durability.

When it comes to market application, understanding the materials used in composite deck boards can help consumers make informed decisions. Different brands may offer varying compositions, which can affect overall performance and quality. For instance, some products may contain a higher percentage of wood fibers, which can enhance the natural appearance of the decking but may also make it more susceptible to moisture damage. On the other hand, boards with a higher plastic content may be more durable but could lack the traditional wood look that some homeowners desire.

To ensure quality assurance, consumers should look for composite deck boards that come with warranties. Many manufacturers provide warranties ranging from 10 to 25 years, indicating their confidence in the product’s longevity. A strong warranty is often a sign that a company stands behind its materials and manufacturing processes, providing an added layer of assurance for buyers.

In addition to warranties, consumers should also consider certifications when evaluating composite deck boards. Various organizations test and certify decking materials for factors such as slip resistance, impact resistance, and environmental sustainability. For instance, products that have been certified by the Forest Stewardship Council or the American Society for Testing and Materials can offer increased confidence in their quality. These certifications ensure that the materials used in the decking have been sourced responsibly and that they meet specific performance criteria.

Furthermore, customer reviews and feedback can provide valuable insights into the performance and durability of composite deck boards. Potential buyers should research different brands and models to understand how well they hold up in real-world applications. Homeowners who have installed composite decking often share their experiences regarding maintenance, longevity, and overall satisfaction, which can help guide new buyers in their decisions.

In summary, composite deck boards are made from a combination of wood fibers and plastic, creating a durable and low-maintenance option for outdoor spaces. Understanding the materials used in these boards is essential for quality assurance, as it directly impacts their performance and longevity. Consumers should look for reputable brands that utilize advanced manufacturing processes and offer strong warranties and certifications. By taking the time to research and evaluate different options, homeowners can ensure they select high-quality composite decking that meets their needs and enhances their outdoor living experience.

The growing popularity of composite deck boards is a testament to their advantages over traditional wood decking. As more consumers become aware of the benefits of these materials, the market for composite decking continues to expand. By understanding the composition of composite deck boards, consumers can make informed choices that align with their preferences for durability, maintenance, and aesthetics. In doing so, they can create beautiful outdoor spaces that stand the test of time while enjoying the peace of mind that comes with quality assurance.