Create a Beautiful Outdoor Space with Wood Plastic Composite Outdoor Deck Flooring

Creating a beautiful outdoor space is a goal for many homeowners and designers, and one of the best ways to achieve this is through the use of wood plastic composite outdoor deck flooring. This innovative material combines the beauty of natural wood with the durability of synthetic materials, making it an ideal choice for outdoor environments. From a materials production process perspective, understanding how wood plastic composites are made can help highlight their advantages and encourage their use in outdoor design.

Wood plastic composites, often referred to as WPC, are engineered products made from a blend of wood fibers and plastic. The production process begins with the selection of raw materials. The wood fibers used in WPC can come from various sources, including recycled wood products, sawdust, and wood shavings. This not only helps reduce waste but also contributes to an eco-friendly product. The plastic component typically consists of recycled high-density polyethylene or polypropylene, which adds to the sustainability profile of WPC by utilizing materials that would otherwise contribute to landfill waste.

Once the raw materials are sourced, the next step in the production process is the formulation of the composite mixture. This involves combining the wood fibers with the plastic in precise proportions to achieve the desired characteristics of the final product. The mixing process is crucial, as it ensures uniform distribution of the wood and plastic components, which impacts the strength, appearance, and durability of the flooring. Additives such as UV stabilizers, colorants, and anti-fungal agents may also be included in the mix to enhance performance and longevity, especially in outdoor settings where exposure to the elements is a concern.

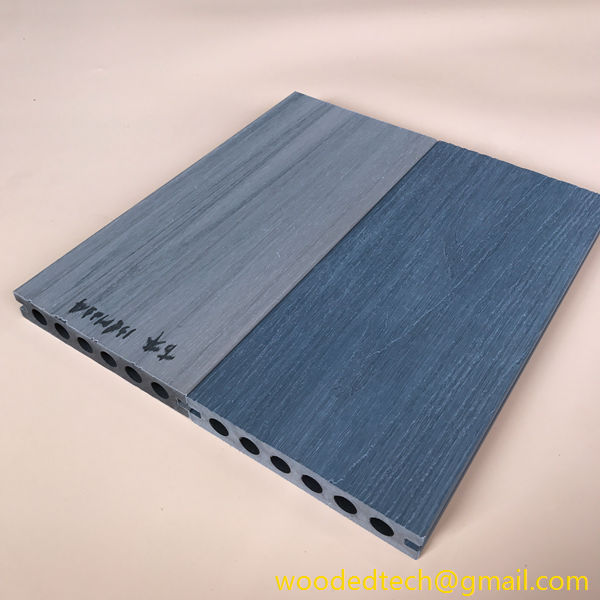

After formulation, the composite mixture is subjected to a process known as extrusion. During extrusion, the blended materials are heated and forced through a mold to create the desired shape and size of the decking boards. This step is critical because it not only determines the dimensions of the final product but also influences its texture and finish. Manufacturers can create various surface patterns, such as wood grain or smooth finishes, to cater to different aesthetic preferences. The extrusion process also allows for the production of boards with integrated features like interlocking systems or grooves for drainage, enhancing the functionality of the decking.

Once extruded, the WPC boards are cooled and cut to size. This phase of production may also involve additional treatments, such as sanding or coating, to ensure a smooth surface that is pleasant to walk on and visually appealing. The final product is then subjected to rigorous quality control measures to verify its strength, durability, and resistance to fading or warping. This quality assurance is essential, especially for products intended for outdoor use where they will face environmental challenges such as moisture, temperature fluctuations, and UV exposure.

One of the significant advantages of wood plastic composite outdoor deck flooring is its low maintenance requirement. Unlike traditional wood decking, which often needs regular staining, sealing, or painting to maintain its appearance and protect against decay, WPC requires minimal upkeep. The composite material is resistant to rot, mold, and insect damage, making it an excellent choice for areas with high humidity or pest activity. This durability translates into a longer lifespan, making WPC a cost-effective solution over time.

Furthermore, the aesthetic versatility of wood plastic composite allows homeowners to create a beautiful outdoor space that complements their overall design vision. WPC is available in a variety of colors and finishes, allowing for customization that can enhance any landscape. Whether one prefers a classic wood look or a modern, sleek design, there is a WPC product to fit the bill.

In conclusion, wood plastic composite outdoor deck flooring is an excellent choice for creating beautiful outdoor spaces. The production process of WPC, which combines sustainable materials and advanced manufacturing techniques, results in a durable, low-maintenance product that meets the demands of outdoor living. With its aesthetic versatility and eco-friendly profile, WPC not only enhances the beauty of outdoor areas but also contributes to a sustainable approach to home design. By choosing wood plastic composites, homeowners can enjoy a stunning outdoor environment that is both functional and environmentally responsible.