A Visual Guide to WPC Decking Images for Inspiration in Your Outdoor Design Projects

When it comes to outdoor design, selecting the right materials is crucial for both aesthetics and functionality. Wood plastic composite (WPC) decking has emerged as a popular choice for homeowners and designers seeking a blend of beauty and durability. Understanding the production process of WPC can enhance your appreciation for this versatile material and inspire your outdoor design projects.

WPC is a composite material made from a combination of wood fibers and plastic. The production process begins with sourcing high-quality wood and plastic materials. The wood fibers are typically derived from recycled wood products, such as sawdust and wood shavings, which are not only environmentally friendly but also contribute to the aesthetic appeal of the decking. The plastic component, often made from recycled polyethylene or polypropylene, enhances the durability and resistance of the material against rot, mold, and insect damage.

Once the raw materials are gathered, they undergo a thorough processing stage. The wood fibers are dried to remove excess moisture, which is essential to prevent warping and ensure a consistent final product. Simultaneously, the plastic is processed to achieve the desired viscosity, which allows for optimal mixing with the wood fibers. This step is critical, as the ratio of wood to plastic can significantly affect the performance and appearance of the final decking boards.

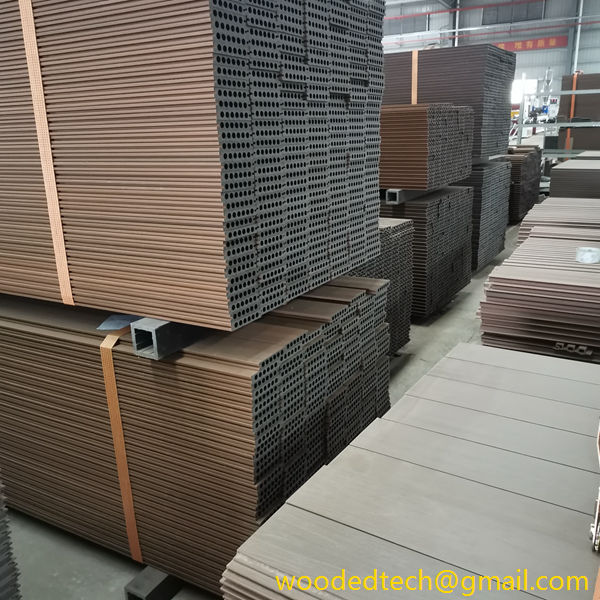

The next phase involves blending the wood fibers with the plastic in a process known as extrusion. During this step, the mixture is heated and forced through a mold to form the shape of the decking boards. The extrusion process allows for various profiles and finishes, giving designers the flexibility to choose from a wide range of styles that cater to different aesthetic preferences. The result is a uniform and solid board that can withstand the elements while maintaining its visual appeal.

After extrusion, the WPC decking boards are cooled and cut to the desired lengths. This stage is where customization options become more pronounced. Manufacturers can offer various colors, textures, and finishes to mimic the natural appearance of wood while providing the durability that plastic offers. Some boards may feature a wood grain texture, while others may have a smooth finish, allowing designers to select options that align with their outdoor vision.

Quality control is a vital aspect of the production process as well. Each batch of WPC decking undergoes rigorous testing to ensure it meets industry standards for strength, durability, and safety. This includes tests for slip resistance, water absorption, and UV stability. The stringent quality assurance measures in place ensure that the final product is not only beautiful but also reliable for outdoor use.

One of the most significant advantages of WPC decking is its low maintenance requirements. Unlike traditional wood decking, which often requires regular staining, sealing, and treatment to maintain its appearance, WPC boards are designed to resist fading and staining. This characteristic makes them an attractive option for homeowners looking to reduce upkeep time while still creating a stunning outdoor space. A simple wash with soap and water is usually sufficient to keep the decking looking fresh.

From a design perspective, WPC decking opens up a world of possibilities. The wide range of colors and finishes allows for creative expression in outdoor spaces. Whether you are designing a cozy backyard retreat, a modern patio, or a spacious deck for entertaining, WPC decking can complement various styles. Its versatility enables it to pair beautifully with other materials, such as stone, metal, or glass, creating a harmonious outdoor environment.

In addition to its aesthetic appeal, the sustainability of WPC decking makes it an attractive choice for environmentally conscious consumers. By utilizing recycled materials in its production, WPC decking contributes to reducing waste and minimizing the carbon footprint associated with traditional lumber sourcing. As awareness of environmental issues grows, many homeowners are actively seeking sustainable options for their outdoor projects, making WPC an appealing choice.

In conclusion, understanding the production process of WPC decking can provide valuable insight into its benefits and applications in outdoor design. The combination of wood and plastic results in a durable, low-maintenance material that offers diverse aesthetic options. As you embark on your outdoor design projects, consider the inspiration that WPC decking can provide, allowing you to create beautiful and functional spaces that will stand the test of time. Whether you are looking to revamp an existing area or build a new outdoor retreat, WPC decking is a material worth exploring for its unique blend of style and performance.