Polymer decking has emerged as a popular choice in the construction and landscaping sectors, offering a myriad of advantages over traditional materials such as wood and composite decking. Understanding the production processes involved in creating polymer decking can provide insight into its unique properties, durability, and environmental benefits.

At its core, polymer decking is made from various types of plastics, primarily polyvinyl chloride (PVC) and polyethylene. The production process typically begins with the selection of high-quality raw materials, which are essential for ensuring the final product’s performance and longevity. These materials are chosen for their resistance to moisture, UV radiation, and general wear and tear, making them ideal for outdoor applications.

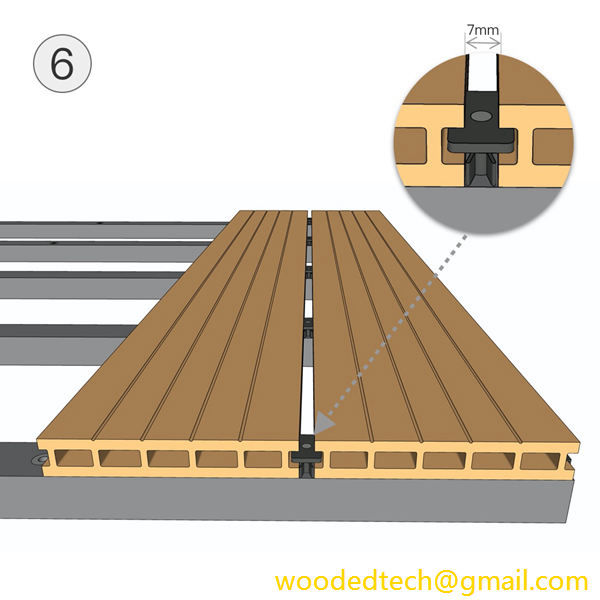

The manufacturing process can be broken down into several key stages. Initially, the raw plastic resins are fed into an extruder, a machine that melts and shapes the material. The extruder heats the plastic to a specific temperature, allowing it to flow and be easily molded. This stage is crucial, as the temperature and pressure must be carefully controlled to achieve the desired consistency. Once the plastic reaches the appropriate viscosity, it is forced through a die that shapes it into the desired profile, such as planks or tiles.

After the extrusion process, the newly formed polymer decking undergoes cooling. This is typically achieved through a water bath or air cooling system, which solidifies the material and ensures it retains its shape. This cooling process is vital as it helps to prevent warping or deformities that could compromise the decking’s structural integrity.

In some cases, manufacturers may enhance the polymer decking by incorporating additives during the production process. These additives can include colorants, UV stabilizers, and anti-microbial agents. Colorants ensure that the decking comes in a variety of appealing shades, allowing homeowners to customize their outdoor spaces. UV stabilizers protect the decking from fading due to sun exposure, while anti-microbial agents inhibit the growth of mold and mildew, ensuring the surface remains clean and aesthetically pleasing.

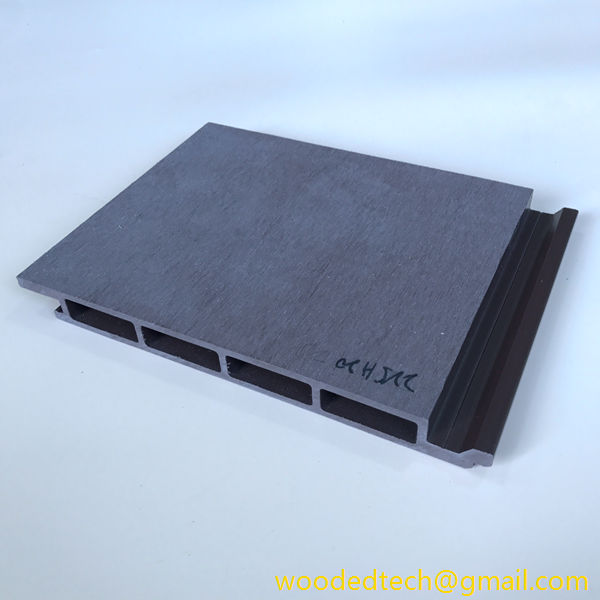

Another critical aspect of polymer decking production is the application of surface textures. Some manufacturers use techniques such as embossing or brushing to create a realistic wood grain finish. This aesthetic appeal is one of the unique benefits of polymer decking, as it can mimic the look of traditional wood without the associated maintenance requirements. The texture not only enhances the visual appeal but also provides a slip-resistant surface, making it safer for outdoor use.

Once the decking boards are produced, they undergo rigorous quality control tests to ensure they meet industry standards. These tests assess the strength, durability, and resistance to various environmental factors. By adhering to strict quality control measures, manufacturers can guarantee that their polymer decking products will withstand the elements, making them a reliable choice for homeowners and builders alike.

The unique benefits of polymer decking extend beyond its manufacturing process. One of the most significant advantages is its low maintenance requirements. Unlike wood, which needs regular staining and sealing to maintain its appearance and prevent rot, polymer decking requires minimal upkeep. A simple wash with soap and water is often sufficient to keep it looking new. This ease of maintenance not only saves time and effort but also reduces long-term costs for homeowners.

Additionally, polymer decking is highly resistant to natural elements. It does not absorb moisture, which means it will not warp, splinter, or crack over time. This resilience makes it an ideal choice for regions with extreme weather conditions, as it can withstand heavy rain, intense sunlight, and fluctuating temperatures without losing its structural integrity.

Another benefit worth mentioning is the environmental aspect of polymer decking. Many manufacturers are committed to sustainability and incorporate recycled materials into their products. This use of recycled plastics helps to reduce waste and lessen the environmental impact associated with traditional wood decking, which often involves deforestation. By choosing polymer decking, consumers can make a more eco-friendly choice for their outdoor spaces.

In conclusion, polymer decking represents a significant advancement in outdoor construction materials. Understanding the production processes involved reveals the care and precision that go into creating this durable and attractive option. With its low maintenance requirements, resistance to environmental factors, and commitment to sustainability, polymer decking offers unique benefits that make it an appealing choice for homeowners and builders alike. As the demand for innovative and eco-friendly building materials continues to grow, polymer decking is poised to remain a popular choice in the years to come.