Benefits of WPC Co-Extrusion Wall Cladding for Durability

Wood Plastic Composite, commonly known as WPC, has emerged as a revolutionary material in the construction and design sectors, particularly in the realm of wall cladding. The market for WPC co-extrusion wall cladding has experienced substantial growth, driven by its unique benefits, especially in terms of durability. As industries and homeowners alike seek sustainable and long-lasting solutions for their building needs, WPC co-extrusion wall cladding stands out as an optimal choice. This article explores the myriad benefits of this innovative material, focusing on its durability and the implications for various market applications.

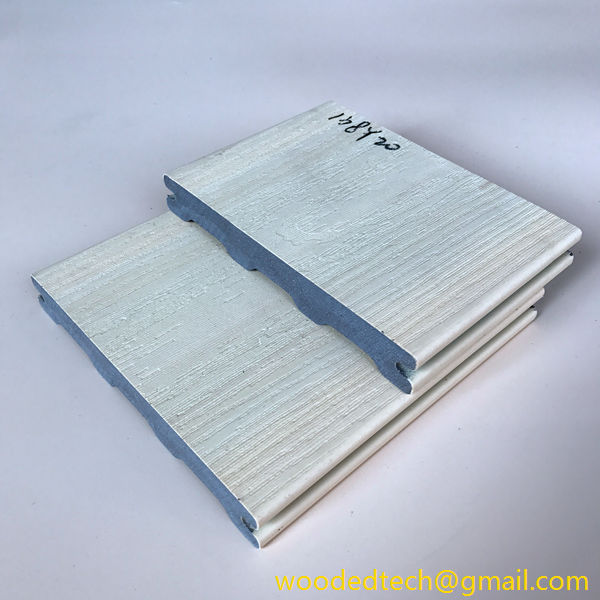

One of the primary advantages of WPC co-extrusion wall cladding is its inherent resistance to environmental factors. Traditional materials, such as wood and vinyl, often succumb to the negative effects of weather, moisture, and UV radiation over time. In contrast, WPC co-extrusion wall cladding is designed to withstand these elements. The co-extrusion process involves encasing a core made of wood plastic composite in a protective layer of high-performance polymer. This outer layer provides an additional line of defense against water absorption, mold growth, and fading due to sunlight exposure.

The durability of WPC co-extrusion wall cladding translates into a significantly longer lifespan compared to conventional materials. In residential and commercial construction, the longevity of building materials can lead to substantial cost savings over time. The reduced need for frequent repairs or replacements associated with WPC wall cladding allows property owners to allocate their budgets more effectively. Additionally, this durability can enhance property values, as potential buyers often prioritize homes and buildings that require less maintenance and have proven longevity.

The durability of WPC co-extrusion wall cladding translates into a significantly longer lifespan compared to conventional materials. In residential and commercial construction, the longevity of building materials can lead to substantial cost savings over time. The reduced need for frequent repairs or replacements associated with WPC wall cladding allows property owners to allocate their budgets more effectively. Additionally, this durability can enhance property values, as potential buyers often prioritize homes and buildings that require less maintenance and have proven longevity.

Another factor contributing to the durability of WPC co-extrusion wall cladding is its resistance to pests and insects. Traditional wood materials are susceptible to infestations from termites and other wood-boring insects, which can compromise the structural integrity of a building. WPC, on the other hand, combines wood fibers with plastic, creating an environment that is inhospitable to pests. This characteristic not only protects the material itself but also contributes to the overall safety and reliability of the building structure. For regions prone to pest-related issues, opting for WPC co-extrusion wall cladding can be a strategic decision to mitigate potential damages and costs associated with pest control.

Sustainability is another significant aspect of WPC co-extrusion wall cladding that appeals to environmentally conscious consumers and businesses. The composite material is typically made from recycled wood fibers and plastic, making it an eco-friendly alternative to traditional wood products. The manufacturing process of WPC also has a lower environmental impact compared to the production of pure wood or plastic products. By choosing WPC co-extrusion wall cladding, businesses can align their construction practices with sustainability goals, appealing to a growing demographic of environmentally aware consumers.

In addition to its durability and sustainability, WPC co-extrusion wall cladding offers aesthetic versatility, allowing for creative design possibilities. Available in various colors, textures, and finishes, WPC can mimic the appearance of natural wood without the associated maintenance challenges. This versatility enables architects and designers to incorporate WPC cladding into a wide range of architectural styles, from modern to rustic. As the market for unique and visually appealing building materials continues to expand, WPC co-extrusion wall cladding presents an attractive option for those looking to enhance the visual appeal of their properties without sacrificing durability.

Moreover, the installation process of WPC co-extrusion wall cladding is relatively straightforward, which can further contribute to its market appeal. The lightweight nature of the material makes it easier to handle and install compared to heavier alternatives. This ease of installation can lead to reduced labor costs and time savings during construction projects. For contractors, this efficiency translates into increased productivity, allowing them to take on more projects without compromising quality.

The growing demand for WPC co-extrusion wall cladding is also fueled by the increasing awareness of energy efficiency in building design. WPC materials can provide better insulation compared to traditional materials, helping to regulate indoor temperatures and reduce energy consumption. As energy costs continue to rise, property owners are seeking solutions that not only enhance durability but also improve energy efficiency. By opting for WPC co-extrusion wall cladding, they can achieve both objectives, making it a smart investment for the future.

In conclusion, the benefits of WPC co-extrusion wall cladding for durability are vast and varied. From its resistance to environmental factors and pests to its sustainable nature and aesthetic versatility, WPC presents a compelling case for its adoption in various market applications. As industries and consumers increasingly prioritize durability and sustainability, WPC co-extrusion wall cladding is poised to play a significant role in the future of construction and design. By embracing this innovative material, stakeholders can enjoy the advantages of long-lasting, low-maintenance building solutions that align with modern values and environmental considerations. As the market continues to evolve, the potential for WPC co-extrusion wall cladding remains promising, making it an essential consideration for any construction project.