Choose the Right Wood Plastic Deck Boards for Your Outdoor Project

Choosing the right wood plastic deck boards for your outdoor project is essential for ensuring durability, aesthetics, and functionality. Wood plastic composite materials have gained popularity in recent years due to their unique properties and advantages over traditional wood. When selecting the appropriate deck boards, it is crucial to consider various factors, including the manufacturing process, material composition, and performance characteristics.

The production of wood plastic composite materials involves a combination of wood fibers and plastic resins. This composite manufacturing process typically begins with the selection of raw materials. The wood fibers can be sourced from various types of wood, including recycled wood products, sawdust, or wood chips. The choice of wood type can significantly influence the visual appeal and structural integrity of the final product. For instance, hardwood fibers may provide a more attractive finish but could be more expensive than softwood options.

Once the wood fibers are selected, they are dried and blended with plastic resins. The most common plastics used in the production of wood plastic composites are polyethylene and polypropylene. These plastics contribute to the material’s resistance to moisture, rot, and insects, making it an excellent choice for outdoor applications. The blending process is crucial as it ensures an even distribution of the plastic within the wood fibers, which is essential for achieving optimal performance characteristics.

After blending, the mixture undergoes a process called extrusion. During this stage, the blended material is heated and forced through a mold to create the desired shape of the deck boards. The extrusion process not only shapes the boards but also enhances their density and strength. The temperature and pressure applied during extrusion play a vital role in determining the final properties of the deck boards, including their flexibility and resistance to warping.

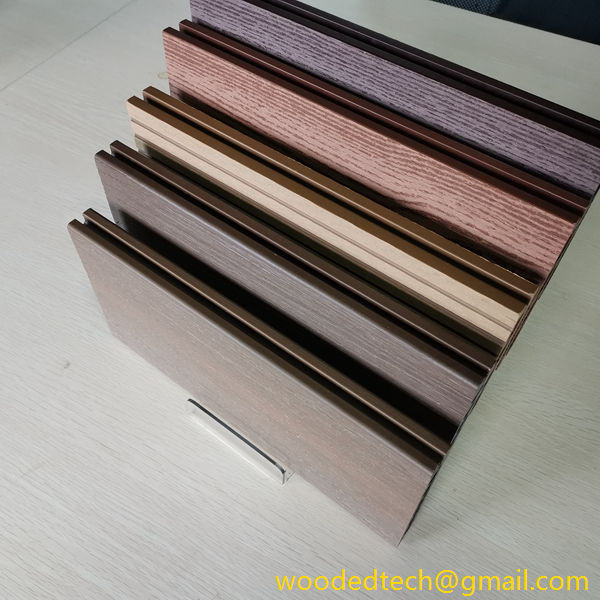

Another critical aspect of the manufacturing process is the addition of additives. These additives can include UV stabilizers, colorants, and antioxidants. UV stabilizers protect the surface of the deck boards from fading due to sun exposure, while colorants allow for a variety of aesthetic options. Antioxidants help to prolong the lifespan of the material by preventing degradation caused by environmental factors. It is important to choose wood plastic composite products that contain high-quality additives to ensure long-lasting performance and visual appeal.

After extrusion, the deck boards are cooled and cut to the desired lengths. At this stage, manufacturers may also perform additional finishing processes, such as sanding or embossing, to enhance the surface texture and grip of the boards. A textured surface can provide better traction, reducing the risk of slips and falls in wet conditions. When selecting deck boards, it is essential to consider the surface finish, as it can significantly impact the overall safety and aesthetics of your outdoor space.

Moreover, it is crucial to evaluate the performance characteristics of the wood plastic deck boards. One of the primary benefits of composite materials is their low maintenance requirements compared to traditional wood. Wood plastic composites do not require painting, staining, or sealing, which can save time and money over the years. Additionally, they are resistant to fading, staining, and scratching, making them ideal for high-traffic areas.

Another important factor to consider is the environmental impact of the materials used. Many manufacturers prioritize sustainability by sourcing recycled materials and employing eco-friendly production processes. When choosing wood plastic deck boards, look for products that are certified by reputable organizations, indicating that they meet strict environmental standards.

In conclusion, selecting the right wood plastic deck boards for your outdoor project involves careful consideration of various factors, including the manufacturing process, material composition, and performance characteristics. By understanding the production methods and the properties of the materials used, homeowners can make informed decisions that will enhance the durability, aesthetics, and functionality of their outdoor spaces. Investing time in research and selecting high-quality wood plastic composite products will ultimately lead to a more satisfying and long-lasting outdoor experience.