Exploring the co extrusion process of outdoor wood-plastic composite materials: the journey of the birth of plastic layers with excellent performance and functions

In our country, outdoor wood-plastic composite materials are increasingly widely used and are favored by consumers for their excellent environmental performance, durability and aesthetics. Among them, the application of co extrusion technology has undoubtedly brought new breakthroughs to the development of wood-plastic composite materials. This article will focus on the co extrusion process of outdoor wood-plastic composite materials and take you to learn more about the charm of this innovative process.

1. Definition and advantages of co extrusion process

The co extrusion process, as the name suggests, refers to the co extrusion of two or more materials through a co extrusion machine to form a composite material with specific structure and properties. In the field of outdoor wood-plastic composite materials, the co extrusion process is to extrude a functional plastic layer with excellent properties based on the original wood-plastic composite material base material. This innovative process offers the following advantages:

1. Improve material performance: The addition of functional plastic layers significantly improves the weather resistance, wear resistance, and aging resistance of wood-plastic composite materials.

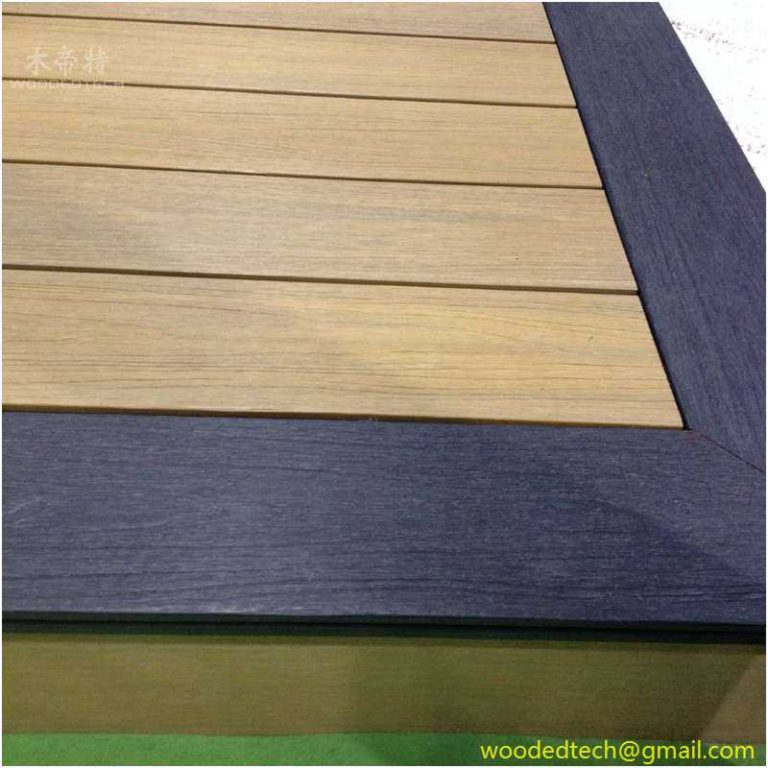

2. Enhance aesthetics: The functional plastic layer can be customized with different colors and textures according to needs, making the product more aesthetically pleasing.

3. Improve environmental performance: The co extrusion process reduces waste emissions during the production of traditional wood-plastic composite materials and reduces environmental pollution.

4. Cost saving: The co extrusion process simplifies the production process and reduces production costs.

2. Application of co extrusion technology in outdoor wood-plastic composite materials

1. Outdoor flooring: Based on the original wood-plastic flooring, co extrusion wood-plastic flooring adds a wear-resistant, anti-aging, and anti-slip functional plastic layer to make the floor more durable during use.

2. Outdoor fence: Co extrusion wood-plastic fence adds a layer of anti-corrosion, anti-aging, weather-resistant and other functional plastic layers to the base material to make it last longer in the outdoor environment.

3. Outdoor landscape: Co extrusion wood-plastic landscape products, such as tables, chairs, flower boxes, etc., are added with functional plastic layers to make them more stable in outdoor environments and less likely to deform and fade.

3. Development prospects of co extrusion technology

With the continuous improvement of environmental awareness, the application of wood-plastic composite materials in the outdoor field will become more and more extensive. As an innovative technology, the co extrusion process will bring the following development prospects to the wood-plastic composite industry:

1. Continuous improvement of product performance: By continuously optimizing the co extrusion process, the performance of the functional plastic layer is improved, making wood-plastic composite materials more competitive in outdoor environments.

2. Rich and diverse product categories: The application of co extrusion technology allows wood-plastic composite materials to produce more products with special properties and aesthetics to meet the needs of different fields and consumers.

3. Industrial chain extension: The development of co extrusion technology will drive the development of related industrial chains, such as plastic raw materials, extrusion equipment, molds, etc.

In short, the application of outdoor wood-plastic composite co extrusion technology has brought new opportunities to my country’s wood-plastic composite industry. In future development, we should continue to increase technological innovation, promote the widespread application of co extrusion technology in the field of wood-plastic composite materials, and contribute to my country’s environmental protection cause.