Explore the Advantages of WPC Co Extrusion Cladding

Wood Plastic Composite (WPC) co-extrusion cladding is an innovative building material that has gained significant popularity in recent years. This technology combines the aesthetics of natural wood with the durability of synthetic materials, resulting in a product that offers numerous advantages from a materials performance perspective. In this article, we will explore the various benefits of WPC co-extrusion cladding, focusing on its durability, maintenance requirements, environmental impact, and versatility.

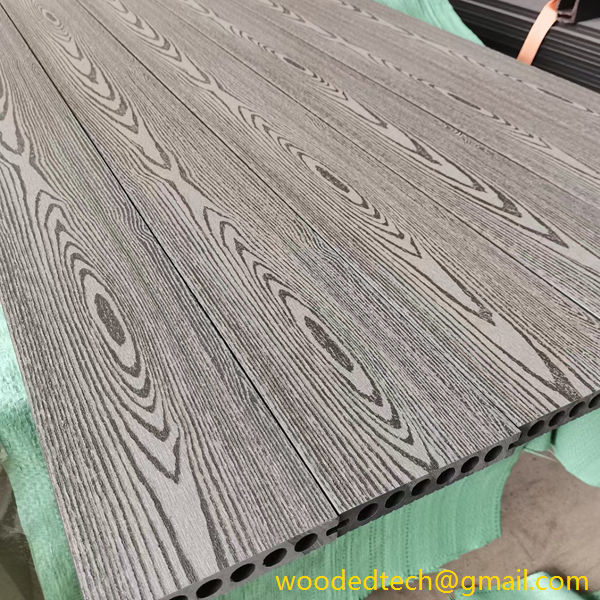

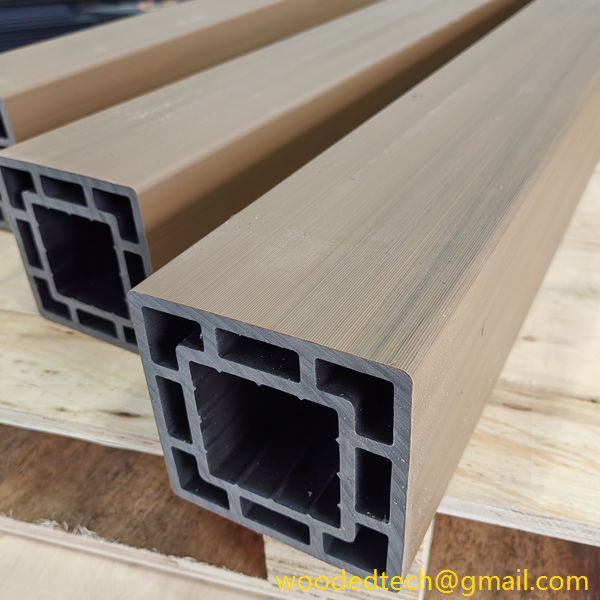

One of the most significant advantages of WPC co-extrusion cladding is its exceptional durability. Traditional wood cladding is susceptible to a range of environmental factors, including moisture, UV radiation, and pests. Over time, these elements can lead to warping, cracking, and decay. In contrast, WPC co-extrusion products are engineered to withstand these challenges. The co-extrusion process involves encasing a core of recycled wood and plastic within a protective outer layer. This outer layer is designed to provide enhanced resistance to fading, staining, and scratching, making WPC cladding an ideal choice for exterior applications. This durability ensures that buildings clad in WPC maintain their aesthetic appeal and structural integrity over time.

Another notable benefit of WPC co-extrusion cladding is its low maintenance requirements. Unlike traditional wood, which often requires regular staining, sealing, and painting to maintain its appearance and protect it from the elements, WPC cladding is designed for minimal upkeep. Homeowners and building managers can enjoy the beauty of wood without the associated labor and costs of maintenance. Cleaning is typically as simple as using soap and water to remove dirt and grime. This ease of maintenance translates into long-term cost savings and makes WPC cladding an attractive option for both residential and commercial properties.

From an environmental perspective, WPC co-extrusion cladding offers several advantages. The materials used in WPC are often sourced from recycled wood fibers and plastic, which helps reduce waste and decrease the demand for virgin materials. By using recycled content, WPC manufacturers contribute to a more sustainable building industry. Furthermore, WPC products are designed to have a long lifespan, which means they do not need to be replaced as frequently as traditional materials. This longevity helps to reduce the overall environmental footprint of construction projects. Additionally, WPC is often free from harmful chemicals commonly found in treated wood products, making it a safer choice for both the environment and human health.

Versatility is another key benefit of WPC co-extrusion cladding. Available in a wide range of colors, finishes, and textures, WPC products can easily mimic the appearance of natural wood while providing the advantages of synthetic materials. This versatility allows architects and designers to achieve their desired aesthetic while ensuring that the building materials can withstand the test of time. Whether used in residential homes, commercial buildings, or outdoor structures, WPC cladding can be tailored to meet the specific design requirements of any project.

In addition to its visual appeal, WPC co-extrusion cladding also offers excellent thermal performance. The composite nature of the material helps to insulate buildings, reducing energy consumption for heating and cooling. This makes WPC cladding an energy-efficient solution that can contribute to lower utility bills and a reduced carbon footprint. In an age where energy efficiency is a critical consideration for new construction and renovations, the thermal properties of WPC are a significant advantage.

Furthermore, the installation of WPC co-extrusion cladding is often more straightforward than traditional cladding materials. Many WPC products are designed for easy assembly, with interlocking systems that simplify the installation process. This ease of installation can lead to reduced labor costs and faster project completion times. Additionally, the lightweight nature of WPC makes it easier to handle and transport, further enhancing its appeal for builders and contractors.

In conclusion, WPC co-extrusion cladding presents a multitude of advantages from a materials performance perspective. Its durability ensures that it can withstand harsh environmental conditions, while its low maintenance requirements save time and money for property owners. The use of recycled materials contributes to sustainability, and its versatility allows for a wide range of design possibilities. With excellent thermal performance and ease of installation, WPC co-extrusion cladding stands out as a superior choice for modern construction projects. As the building industry continues to evolve, WPC cladding is poised to play a significant role in shaping the future of exterior building materials.