Explore Wood Plastic Composite Exterior Wall Cladding for Modern Homes

Wood Plastic Composite, commonly referred to as WPC, has emerged as a popular choice for exterior wall cladding in modern homes. This innovative material combines the natural aesthetic of wood with the durability and low-maintenance characteristics of plastic, making it an ideal choice for homeowners seeking both beauty and functionality. The production processes involved in creating WPC are essential to understanding its advantages, applications, and sustainability.

The manufacturing of Wood Plastic Composite typically involves the blending of wood fibers, which can be sourced from wood flour or reclaimed wood, with thermoplastic resins. The most commonly used plastics in WPC production include polyethylene, polypropylene, and polyvinyl chloride. The selection of materials is crucial as it determines the final properties of the composite, including its strength, flexibility, and resistance to environmental factors.

The first step in the production process is the preparation of the raw materials. Wood fibers are processed to achieve a consistent size and moisture content, which is vital for ensuring a uniform final product. The plastic resins are also prepared, often involving the addition of additives such as UV stabilizers, color pigments, and anti-fungal agents. These additives enhance the performance and appearance of the WPC, making it more suitable for outdoor applications where exposure to sunlight and moisture is a concern.

Once the materials are prepared, they are blended together in a process called compounding. This typically occurs in a twin-screw extruder, where the wood fibers and plastic resins are mixed under heat and pressure. The extrusion process ensures that the wood and plastic are evenly distributed, resulting in a homogeneous material that retains the desirable properties of both components. The temperature during extrusion is carefully controlled to prevent degradation of the wood fibers while ensuring the plastic melts adequately for proper mixing.

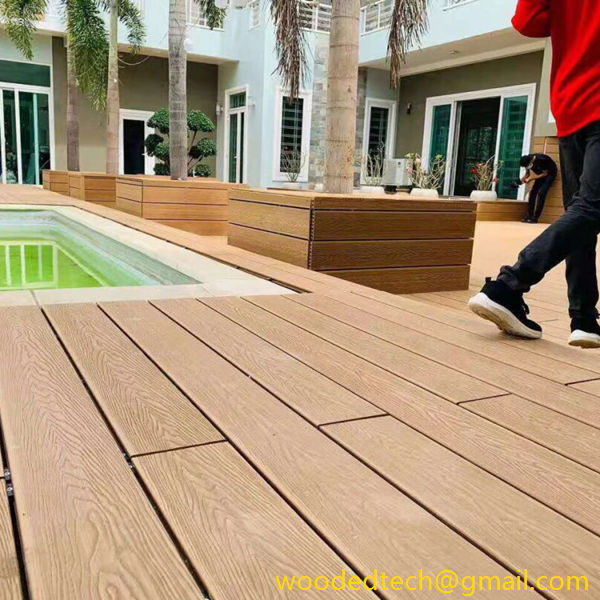

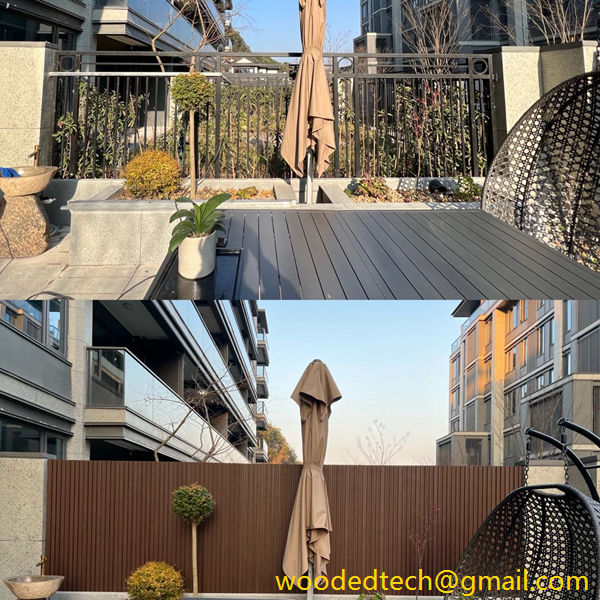

After compounding, the WPC is shaped into the desired profile through an extrusion process. During this phase, the molten composite is forced through a die that forms it into planks or boards suitable for wall cladding. The extruded profiles can be further treated or textured to enhance their appearance and replicate the look of natural wood. This versatility in design allows architects and builders to create visually appealing facades that complement modern architectural styles.

Cooling systems are employed to solidify the extruded WPC profiles. Once cooled, the boards are cut into manageable lengths and can undergo additional finishing processes, such as sanding or coating, to improve their surface finish and color. These finishing touches are essential for enhancing the aesthetic appeal and ensuring that the cladding meets the design specifications required for modern homes.

One of the standout features of Wood Plastic Composite is its resistance to environmental factors. Unlike traditional wood, WPC does not warp, splinter, or decay when exposed to moisture or extreme weather conditions. This durability makes it an excellent choice for exterior applications, where longevity and minimal maintenance are paramount. Additionally, WPC is resistant to pests such as termites, further increasing its lifespan and reducing the need for chemical treatments.

From a sustainability perspective, Wood Plastic Composite offers significant benefits. The use of recycled wood and plastic materials in its production helps reduce waste and conserves natural resources. This eco-friendly approach aligns with the growing demand for sustainable building materials in modern construction. Moreover, WPC is fully recyclable at the end of its life cycle, making it a responsible choice for environmentally conscious homeowners.

The installation process of WPC exterior wall cladding is another aspect that adds to its appeal. The lightweight nature of the material makes it easier to handle and install compared to traditional wood cladding. Additionally, WPC can be attached using standard tools and fasteners, which streamlines the construction process and reduces labor costs.

In conclusion, Wood Plastic Composite exterior wall cladding represents a remarkable advancement in building materials for modern homes. The production process, from raw material preparation to final extrusion and finishing, plays a crucial role in defining the properties and performance of WPC. Its blend of aesthetic appeal, durability, and sustainability positions it as a leading choice for homeowners and builders seeking innovative solutions for exterior cladding. As the construction industry continues to evolve, the role of materials like WPC will undoubtedly expand, contributing to the development of more sustainable and resilient homes.