Explore Wood Plastic Composite Sheets for Versatile Applications

Wood Plastic Composite Sheets, often referred to as WPC sheets, represent an innovative fusion of wood fibers and plastic materials, resulting in a versatile product that has gained significant popularity in various industries. The production process of WPC sheets involves a series of carefully controlled steps that contribute to their unique properties, making them suitable for a wide range of applications.

The first stage in the production of WPC sheets involves the selection of raw materials. Typically, wood fibers sourced from recycled wood products or sawdust are combined with thermoplastic polymers, such as polyethylene, polypropylene, or polyvinyl chloride. This combination not only enhances the mechanical properties of the final product but also promotes sustainability by utilizing recycled materials. The choice of wood fibers and plastic types can significantly influence the characteristics of the composite, including its strength, durability, and aesthetic appeal.

Once the raw materials are selected, they undergo a process called compounding. During compounding, the wood fibers and plastic are mixed together in a high-temperature, high-shear environment. This process ensures that the wood fibers are evenly distributed within the plastic matrix, creating a homogenous mixture. Additives such as colorants, UV stabilizers, and fire retardants can also be introduced at this stage to enhance the performance and appearance of the WPC sheets. The compounding phase is critical, as it affects the final properties of the composite material, such as its flexibility, strength, and resistance to environmental factors.

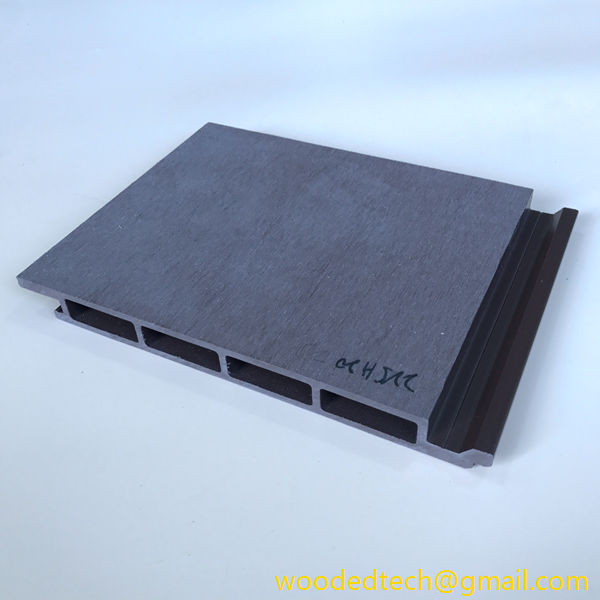

Following compounding, the mixture is extruded into sheets using a specialized extrusion process. The extruder heats the material to a specific temperature, allowing it to flow through a die that shapes it into sheets of desired thickness and width. The extrusion process is carefully monitored to maintain consistent quality and performance of the WPC sheets. Cooling systems are employed to quickly solidify the sheets after extrusion, ensuring they retain their shape and structure.

After the sheets have cooled, they undergo various finishing processes to enhance their appearance and functionality. These processes may include sanding, trimming, and surface treatments. Sanding helps to create a smooth surface, which is essential for applications where aesthetics are important. Surface treatments, such as embossing or coating, can also be applied to improve slip resistance, enhance color, or provide additional protection against weathering and UV exposure.

One of the key advantages of WPC sheets is their versatility. Due to their unique composition, they can be used in a wide range of applications, from outdoor decking and fencing to interior wall cladding and furniture. In outdoor settings, WPC sheets are particularly valued for their resistance to moisture, insects, and decay, making them an excellent alternative to traditional wood materials. In indoor applications, WPC sheets can be designed to mimic the appearance of natural wood while offering the benefits of plastic, such as ease of maintenance and durability.

Moreover, WPC sheets are increasingly being used in the construction and automotive industries. Their lightweight nature reduces transportation costs and simplifies installation processes. Additionally, the customizable nature of WPC sheets allows manufacturers to produce products that meet specific design requirements or regulatory standards, further expanding their application potential.

As sustainability becomes a more pressing concern in manufacturing and construction, WPC sheets stand out as an eco-friendly option. By utilizing recycled materials and offering a longer lifespan than traditional wood products, WPC sheets contribute to reducing waste and minimizing the environmental impact of building materials. This aligns with the growing demand for green construction practices and sustainable product offerings.

In conclusion, the production of Wood Plastic Composite Sheets involves a meticulous process of selecting raw materials, compounding, extruding, and finishing. These processes contribute to the unique properties of WPC sheets, making them suitable for various applications across multiple industries. Their versatility, durability, and sustainability make WPC sheets an attractive alternative to traditional materials, paving the way for innovative solutions in construction, furniture design, and outdoor living spaces. As technology continues to advance, the potential for WPC sheets in new applications will likely expand, further solidifying their role in modern manufacturing and design.