Find Reliable Wood Plastic Composite Manufacturers for Your Projects

Finding reliable wood plastic composite manufacturers is crucial for the success of any construction or design project. Wood plastic composite, commonly known as WPC, is a material made from a blend of wood fibers and plastic. It has gained popularity in recent years due to its durability, low maintenance, and aesthetic appeal. When embarking on a project that requires WPC, selecting the right manufacturer can significantly impact the quality and longevity of the final product.

The first step in identifying trustworthy WPC manufacturers is to conduct thorough research. Begin by exploring the online presence of potential manufacturers. Look for their websites, product catalogs, and any available customer reviews. A reputable manufacturer will typically provide detailed information about their products, including specifications, applications, and the production process. Transparency is a key indicator of reliability, so be wary of manufacturers who hesitate to share information about their practices and materials.

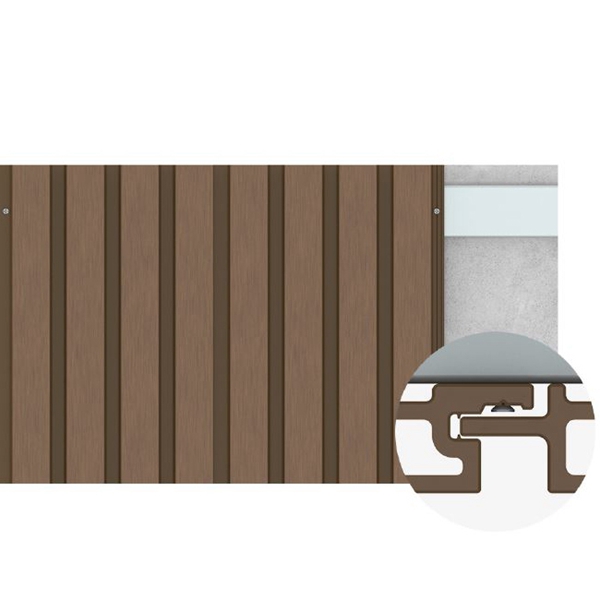

Understanding the production process of wood plastic composites is vital. A reliable manufacturer should have a well-established production process that ensures consistency in quality. This process typically involves the mixing of wood fibers, polyethylene or polypropylene, and additives under controlled conditions. It is essential to inquire about the types of wood and plastic used in the composite, as well as the additives that may enhance performance. Manufacturers that prioritize sustainable practices often use recycled materials and eco-friendly additives, contributing to a more environmentally friendly product.

In addition to the production process, it is important to assess the quality control measures implemented by the manufacturer. A reputable WPC manufacturer will have stringent quality control protocols in place to monitor every stage of production. This includes testing raw materials, monitoring the manufacturing process, and conducting final inspections of the finished products. Inquire about the certifications and standards the manufacturer adheres to, such as ASTM or ISO certifications. These certifications signify that the manufacturer meets specific quality and safety standards, which can provide additional peace of mind.

Another important factor to consider is the range of products offered by the manufacturer. A reliable WPC manufacturer should provide a diverse selection of products to meet various project needs. This includes different sizes, colors, and finishes, allowing for greater design flexibility. Additionally, manufacturers that offer customizable solutions can be particularly advantageous for unique projects. It is worth discussing your specific project requirements with potential manufacturers to determine if they can accommodate your needs.

Customer service is another critical aspect to evaluate when seeking a WPC manufacturer. A reliable manufacturer should be responsive to inquiries and willing to provide assistance throughout the purchasing process. This includes providing samples, answering questions about product specifications, and offering guidance on installation and maintenance. Good customer service can make a significant difference, especially if issues arise during a project. Establishing a good rapport with the manufacturer can facilitate smoother communication and problem-solving.

Furthermore, consider the manufacturer’s reputation within the industry. Look for testimonials or case studies from previous clients to gauge their experience with the manufacturer. A strong reputation often indicates a history of delivering high-quality products and exceptional service. Networking within industry circles or attending trade shows can also provide insights into which manufacturers are highly regarded.

Lastly, evaluate the manufacturer’s pricing and delivery terms. While cost should not be the sole determining factor, it is essential to find a manufacturer that offers competitive pricing without compromising quality. Inquire about bulk order discounts or loyalty programs that may benefit your project. Additionally, timely delivery is critical in ensuring project schedules are met. A manufacturer that can provide a reliable timeline for delivery can help you avoid potential delays.

In conclusion, finding reliable wood plastic composite manufacturers requires careful consideration of various factors, including production processes, quality control measures, product range, customer service, reputation, pricing, and delivery terms. By conducting thorough research and asking the right questions, you can identify manufacturers that align with your project needs and ensure the successful implementation of wood plastic composites in your construction or design endeavors. The right manufacturer will not only provide high-quality materials but also contribute to the overall success and satisfaction of your project.