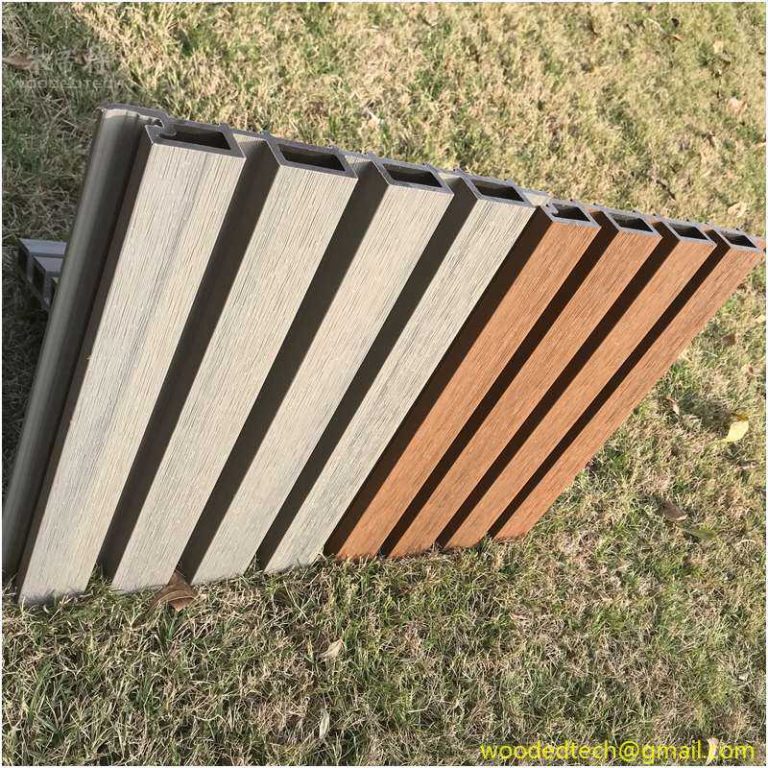

Recycled plastic wood cladding

Recycled new life, green upgrade: the dual vitality of outdoor Recycled plastic wood cladding

With the continuous improvement of environmental awareness, people are paying more and more attention to sustainable development and green life. In this context, outdoor Recycled plastic wood cladding came into being, and its unique advantages have become the new favorite in the field of modern architecture. This article will start with the two recycling meanings of outdoor Recycled plastic wood cladding, and discuss in detail its green environmental protection and recycling characteristics.

1. Raw material recycling: recycled plastic and wood powder

The raw materials of outdoor Recycled plastic wood cladding are produced using recycled plastic and wood powder. As renewable resources, plastic and wood powder have the following advantages:

1. Resource conservation: Recycling waste plastic and wood powder reduces the waste of resources and helps to alleviate the problem of resource shortage in my country.

2. Reduce pollution: Recycling waste plastic and wood powder reduces environmental pollution and helps to achieve green development.

3. Reduce costs: Using waste plastic and wood powder as raw materials reduces production costs, making outdoor Recycled plastic wood cladding more cost-effective.

2. Regeneration of wallboards themselves: recycling

After years of use, outdoor Recycled plastic wood cladding can be recycled again. The following is the specific process of wallboard recycling:

1. Recycling: Recycle the discarded outdoor Recycled plastic wood cladding to avoid long-term accumulation in the environment and pollution.

2. Crushing: Crush the recycled wallboards into powder to provide raw materials for re-production.

3. Reproduction: Use the crushed wallboard powder, add an appropriate amount of new materials, mix them in a certain proportion, and produce new outdoor Recycled plastic wood cladding again.

4. Application: Apply the newly produced wallboards to the construction field to achieve the recycling of resources.

The following is the regeneration of outdoor Recycled plastic wood cladding:

1. Extend the service life: Through recycling, the service life of outdoor Recycled plastic wood cladding is extended, reducing the resource consumption in the construction field.

2. Improve environmental performance: The wallboard regeneration process reduces environmental pollution and is conducive to the realization of green buildings.

3. Optimize resource allocation: The production and application of recycled wallboards can help optimize resource allocation and improve resource utilization efficiency.

III. Application prospects of outdoor Recycled plastic wood cladding

1. Construction field: Outdoor Recycled plastic wood cladding can be applied to building exterior walls, interior walls, floors and other fields, with excellent decorative and environmental protection performance.

2. Garden landscape: Outdoor Recycled plastic wood cladding can be applied to garden landscape projects, such as walls, flower beds, seats, etc., to enhance the overall beauty of garden landscape.

3. Municipal engineering: Outdoor Recycled plastic wood cladding can be used in municipal roads, bridges, tunnels and other projects to improve project quality and environmental protection performance.

In short, outdoor Recycled plastic wood cladding has become a new favorite in the field of modern construction with its unique green environmental protection and recycling characteristics. With the continuous improvement of environmental awareness, the application prospects of Recycled plastic wood cladding will become more and more extensive, injecting new vitality into the development of my country’s construction industry.