Stylish Plastic Wood Look Cladding Options for a Contemporary Aesthetic

Stylish plastic wood look cladding options have gained immense popularity in contemporary architecture and design. These innovative materials combine the aesthetic appeal of natural wood with the durability and maintenance ease of synthetic materials. From a materials production process perspective, the creation of plastic wood look cladding involves several critical stages that ensure the final product meets the desired aesthetic and functional requirements.

The journey begins with the selection of base materials. Typically, high-density polyethylene or polyvinyl chloride is used as the primary ingredient for plastic wood cladding. These materials are favored for their resilience against weather elements, pests, and decay, making them suitable for external applications. The choice of these polymers is crucial, as they impart the necessary strength and flexibility to the final product.

Once the base materials are selected, the production process moves to the compounding stage. During compounding, the chosen polymers are blended with additives that enhance their performance. These additives may include UV stabilizers to protect against sun damage, colorants to achieve the desired wood-like appearance, and fire retardants to improve safety. The precise formulation of these compounds is essential, as it affects the cladding’s durability, color retention, and overall performance in various environmental conditions.

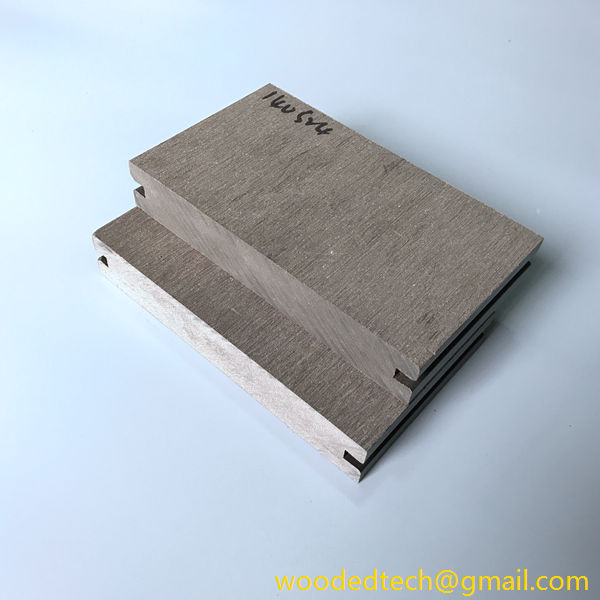

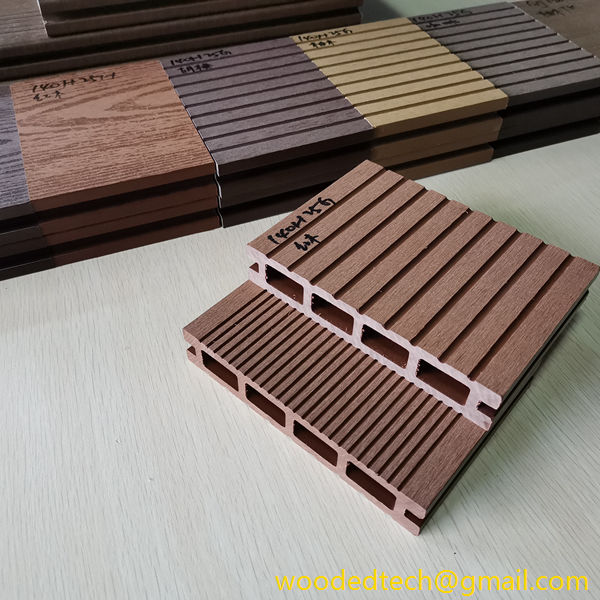

Following compounding, the material undergoes extrusion or molding processes. In extrusion, the compounded material is heated until it becomes malleable and then pushed through a die to form continuous sheets or profiles that mimic the look of natural wood. This method allows for the creation of various shapes and sizes, catering to different design needs. Alternatively, injection molding can be employed for more complex shapes, providing flexibility in design while maintaining consistency in quality.

The next stage is the surface treatment, which plays a vital role in achieving the desired wood-like appearance. Advanced technologies such as embossing and printing are used to create realistic textures and grain patterns on the surface of the cladding. This step is critical, as it enhances the visual appeal and makes the product indistinguishable from real wood at a glance. The surface treatment also adds an additional layer of protection against wear and tear, increasing the cladding’s lifespan.

After surface treatment, the cladding undergoes quality control testing. This process ensures that the finished product meets industry standards for performance, durability, and aesthetics. Tests may include assessing the colorfastness under UV exposure, impact resistance, and moisture absorption levels. Quality assurance is crucial, as it guarantees that the cladding will perform well in various climates and environments while retaining its stylish appearance.

Once the cladding has passed quality control, it is ready for packaging and distribution. The packaging process is designed to protect the cladding during transportation and storage, ensuring that it arrives at its destination in pristine condition. This aspect of the production process is often overlooked but is integral to maintaining customer satisfaction and product integrity.

In terms of installation, plastic wood look cladding offers significant advantages over traditional materials. Its lightweight nature reduces labor costs and installation time, making it an attractive option for builders and contractors. Additionally, the cladding can be easily cut and shaped to fit unique architectural designs, allowing for creativity in contemporary aesthetics.

Moreover, the environmental impact of producing plastic wood cladding has been a subject of discussion. Many manufacturers are now focusing on sustainability by incorporating recycled materials into their products. This practice not only reduces waste but also appeals to environmentally conscious consumers looking for sustainable building solutions. The use of recycled content can significantly lower the carbon footprint associated with production, aligning with the growing demand for green building materials.

In conclusion, stylish plastic wood look cladding options represent a significant advancement in building materials, combining aesthetics with practicality. The production process involves careful selection of materials, precise formulation, advanced manufacturing techniques, and rigorous quality control. As the demand for contemporary design continues to rise, these cladding options stand out as a versatile and sustainable choice for architects, builders, and homeowners alike. Their ability to mimic the beauty of natural wood while offering enhanced durability and low maintenance makes them an ideal solution for modern construction projects. As innovations continue to evolve in materials science, we can expect even more exciting developments in the realm of plastic wood look cladding in the future.