The Benefits of WPC Decking Installation for Creating Beautiful and Functional Outdoor Areas

Wood Plastic Composite (WPC) decking has gained considerable popularity in recent years as a preferred choice for outdoor areas. This innovative material combines the natural beauty of wood with the durability and low maintenance of plastic. The integration of these two materials comes from a sophisticated manufacturing process that not only enhances the aesthetic appeal of outdoor spaces but also offers a range of functional benefits. Understanding the production techniques behind WPC can help in appreciating its advantages in creating beautiful and functional outdoor areas.

The production of WPC starts with the careful selection of raw materials. Typically, the primary components are wood fibers and recycled plastic. The wood fibers can come from various sources, including recycled wood products, sawdust, and wood shavings. This use of recycled materials not only contributes to sustainability but also reduces waste in landfills. The plastic component often comes from post-consumer recycled materials like plastic bottles or bags, further enhancing the eco-friendliness of WPC.

Once the raw materials are sourced, they undergo a meticulous process known as compounding. During this phase, the wood fibers and plastic are mixed together in specific ratios. The compounding process often involves the addition of additives such as colorants, UV stabilizers, and anti-fungal agents to enhance the properties of the final product. This stage is crucial, as it determines the overall quality, durability, and appearance of the WPC decking. The blending of wood and plastic not only results in a material that mimics the look of natural wood but also provides superior resistance to moisture, insects, and decay.

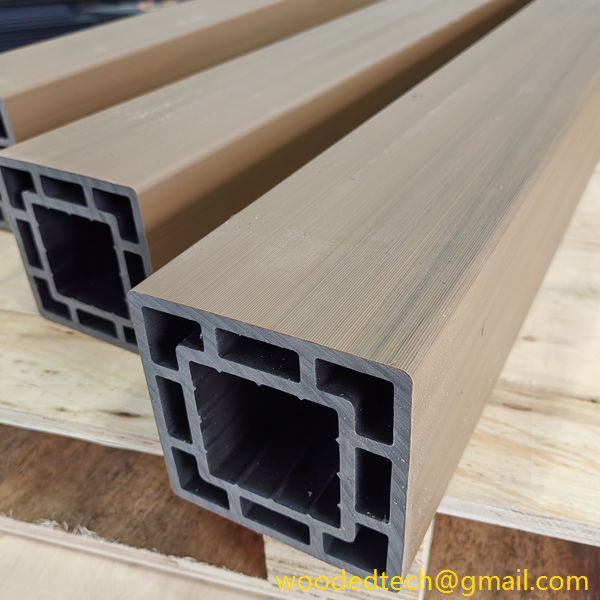

After compounding, the mixture is subjected to a process called extrusion. In this phase, the compounded material is heated and forced through a mold to create the desired shape of the decking boards. The extrusion process allows for a high degree of customization in terms of size, thickness, and surface texture. This flexibility is one of the reasons why WPC decking is available in a variety of styles and colors, catering to different design preferences. The ability to create boards that closely resemble traditional wood while offering enhanced performance characteristics is a significant advantage.

Post-extrusion, the WPC decking boards undergo a cooling process to solidify their shape. This is followed by quality control measures to ensure that each board meets industry standards for strength, durability, and appearance. Manufacturers often conduct tests to evaluate the boards’ resistance to fading, stains, and scratching. This attention to quality during the production process ensures that the final product can withstand the rigors of outdoor environments, making WPC decking a reliable choice for patios, decks, and other outdoor living spaces.

One of the most compelling benefits of WPC decking is its low maintenance requirement. Unlike traditional wood decking, which can warp, splinter, or require regular sealing and staining, WPC decking is designed to resist these issues. The material does not require any special treatments or finishes, making it easy for homeowners to maintain their outdoor areas. A simple cleaning with soap and water is usually sufficient to keep the decking looking new. This feature not only saves time and effort but also reduces the long-term costs associated with maintenance.

Additionally, WPC decking is highly durable, able to withstand extreme weather conditions without deteriorating. It does not absorb moisture, which significantly reduces the risk of mold and mildew growth. This makes it an ideal choice for areas that experience heavy rainfall or humidity. Furthermore, WPC is resistant to fading from UV exposure, ensuring that the colors remain vibrant over time. This durability translates to a longer lifespan for the decking, providing homeowners with peace of mind regarding their investment.

In terms of safety, WPC decking often has a slip-resistant surface, making it a safer option for outdoor areas, especially around pools or in wet conditions. The material’s resistance to splintering also adds to its safety profile, making it suitable for families with children and pets.

In conclusion, the production process of WPC decking plays a vital role in its functionality and aesthetic appeal. By combining recycled wood fibers and plastic through advanced manufacturing techniques, WPC offers a sustainable, durable, and low-maintenance solution for creating beautiful outdoor spaces. The benefits of WPC decking, including its versatility in design, ease of maintenance, and safety features, make it an excellent choice for homeowners looking to enhance their outdoor areas. As the demand for eco-friendly materials continues to rise, WPC decking stands out as a practical and appealing option for modern landscaping and outdoor living.