The WPC Extrusion Process Explained and Its Importance in Producing High-Quality Building Materials

The WPC extrusion process, or Wood Plastic Composite extrusion process, is a critical manufacturing technique that combines wood fibers and plastic polymers to create composite materials. This process is essential in producing high-quality building materials such as decking, railing, and other construction components that require durability and aesthetic appeal. Understanding the intricacies of the WPC extrusion process, along with its installation and maintenance aspects, is vital for manufacturers, builders, and end-users alike.

The WPC extrusion process begins with the careful selection of raw materials. Typically, a mixture of wood flour, plastic polymers, and various additives is used. The wood fibers provide strength and a natural appearance, while the plastic component offers resistance to moisture, insects, and decay. The chosen plastic is often recycled, contributing to environmental sustainability. The blending of these materials occurs in a controlled environment, ensuring a uniform mixture that enhances the final product’s performance.

Once the materials are prepared, they are fed into an extruder, a machine designed to melt and mix the components while shaping them into a continuous profile. The extruder consists of a hopper, a barrel, and a screw mechanism. As the materials move through the barrel, they are subjected to heat and pressure, causing them to melt and become malleable. The design of the screw plays a crucial role in achieving the desired temperature and mixing efficiency. Appropriate temperature settings are essential; too low might not adequately melt the materials, while too high could degrade the polymers.

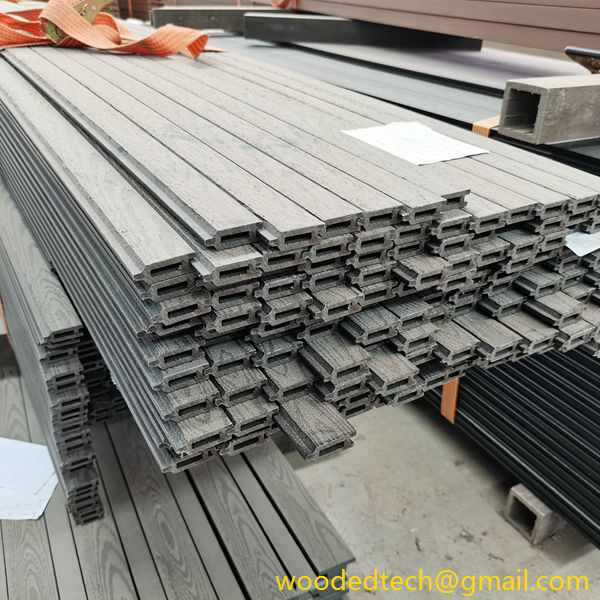

After the materials are adequately mixed and melted, they are forced through a die, which shapes them into the final profile, such as boards or planks. The die design is significant as it determines the dimensions and surface finish of the product. Following extrusion, the material is cooled and solidified, often using water or air cooling methods. The cooling phase is critical; it ensures that the product retains its shape and structural integrity.

The importance of the WPC extrusion process in producing high-quality building materials cannot be overstated. WPC products are known for their durability, low maintenance requirements, and resistance to environmental factors. Unlike traditional wood, which can warp, split, or rot over time, WPC materials remain stable, making them ideal for outdoor applications such as decking and fencing. Additionally, the aesthetic appeal of WPC allows for a variety of finishes and colors, enabling manufacturers to cater to diverse consumer preferences.

From an installation perspective, understanding the properties of WPC materials is crucial. They are generally lighter than solid wood, which simplifies handling and transportation. However, it is essential to follow specific installation guidelines to ensure optimal performance. For instance, proper spacing between boards is necessary to account for thermal expansion and contraction. Additionally, the use of appropriate fasteners and installation techniques can significantly impact the longevity and appearance of the finished product.

Maintenance of WPC materials is relatively straightforward compared to traditional wood products. WPC does not require regular staining or sealing, which can save both time and money for homeowners and builders. Regular cleaning with soap and water is usually sufficient to maintain the material’s appearance. However, it is essential to avoid harsh chemicals or abrasive materials that could damage the surface finish. Over time, some color fading might occur due to UV exposure, but this can often be minimized with proper product selection and maintenance practices.

In conclusion, the WPC extrusion process is a sophisticated manufacturing method that plays a vital role in producing high-quality building materials. Understanding the intricacies of this process, along with the installation and maintenance requirements, is essential for ensuring the long-term performance and aesthetic appeal of WPC products. As the demand for sustainable and durable building materials continues to rise, the importance of the WPC extrusion process will only grow, making it a significant area of focus for manufacturers and builders alike. By embracing this technology and adhering to best practices in installation and maintenance, stakeholders can maximize the benefits of WPC products, contributing to a more sustainable and efficient construction industry.