Understand WPC Cladding Thickness for Your Building Needs

Wood Plastic Composite (WPC) cladding has become a popular choice in modern construction due to its durability, aesthetic appeal, and low maintenance requirements. As the demand for sustainable building materials increases, WPC cladding offers an attractive alternative to traditional wood. One crucial factor in selecting the right WPC cladding for your project is its thickness, which can significantly influence both the performance and cost-effectiveness of the material.

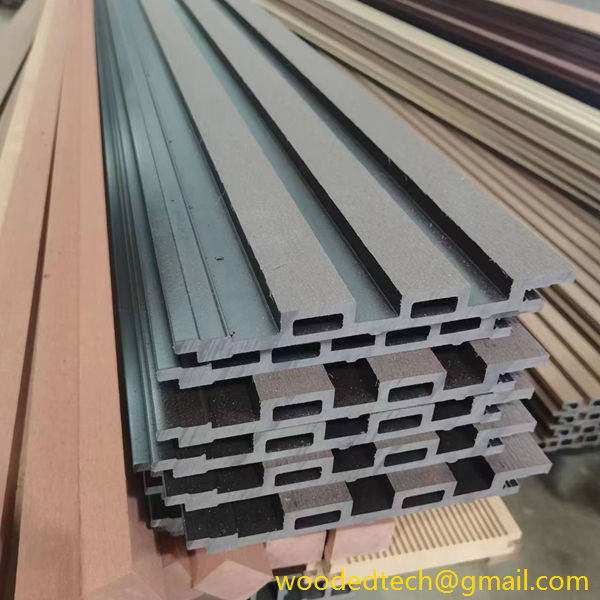

WPC cladding comes in various thicknesses, typically ranging from 6 to 25 millimeters. The thickness you choose can impact not only the appearance and structural integrity of the cladding but also its thermal insulation properties and resistance to environmental factors. Thicker cladding tends to provide better insulation, which can lead to energy savings in heating and cooling your building. Additionally, increased thickness enhances the material’s durability, making it more resistant to warping, cracking, and fading over time. This durability is particularly important in regions with harsh weather conditions, where thinner cladding may not withstand the elements as effectively.

From a global perspective, the distribution of WPC production facilities plays a significant role in determining the availability and pricing of different thicknesses of cladding. Major manufacturers are concentrated in regions with abundant resources and advanced manufacturing capabilities. Countries such as China, the United States, and Germany lead the way in WPC production, leveraging their technological advancements and economies of scale to produce high-quality materials at competitive prices.

The global supply chain for WPC cladding is influenced by several factors, including raw material costs, transportation expenses, and trade regulations. For instance, the availability of recycled materials, such as reclaimed wood and plastic, can affect production costs and, consequently, the final price of WPC cladding. Regions rich in these resources can produce WPC cladding more affordably, giving them a competitive edge in the market.

Price advantages vary widely depending on the thickness of the WPC cladding. Thicker boards typically command higher prices due to the increased amount of raw materials used in their production. However, the long-term benefits of investing in thicker cladding can outweigh the initial costs. Thicker cladding often requires less frequent replacement and maintenance, leading to cost savings over the life of the building. Furthermore, the enhanced insulation properties of thicker materials can contribute to lower energy bills, providing an additional financial incentive for builders and homeowners.

In addition to thickness, other factors such as color, texture, and finish can also influence the price of WPC cladding. Manufacturers often offer a range of options to meet diverse aesthetic preferences, which can further affect pricing. Customization options may come with additional costs, but they can also enhance the overall value of your project by creating a unique and visually appealing exterior.

As you consider WPC cladding for your building needs, it is essential to evaluate not only the thickness but also the overall cost-benefit ratio. Analyzing your specific project requirements, climate conditions, and budget constraints will help you make an informed decision. Consulting with suppliers and manufacturers can provide valuable insights into the best thickness options for your needs and clarify how various factors contribute to pricing.

In conclusion, understanding the thickness of WPC cladding is vital for making the right choice for your building project. By considering the global production landscape and pricing advantages, you can select cladding that meets both your aesthetic and functional requirements. Whether you opt for thinner boards for a cost-effective solution or invest in thicker materials for enhanced durability and insulation, WPC cladding offers a versatile and sustainable option that can help you achieve your building goals. As the market continues to evolve, staying informed about trends in WPC production and pricing will empower you to make decisions that benefit your project in the long run.