Understanding WPC Decking End Caps and Their Importance for a Finished Look and Safety

Wood Plastic Composite (WPC) decking has gained immense popularity in recent years due to its durability, aesthetic appeal, and low maintenance requirements. Among the various components of a WPC decking system, end caps play a crucial role in both the finished appearance and overall safety of the installation. This article delves into the manufacturing processes of WPC decking end caps, their significance in decking applications, and the essential aspects that contribute to their effectiveness.

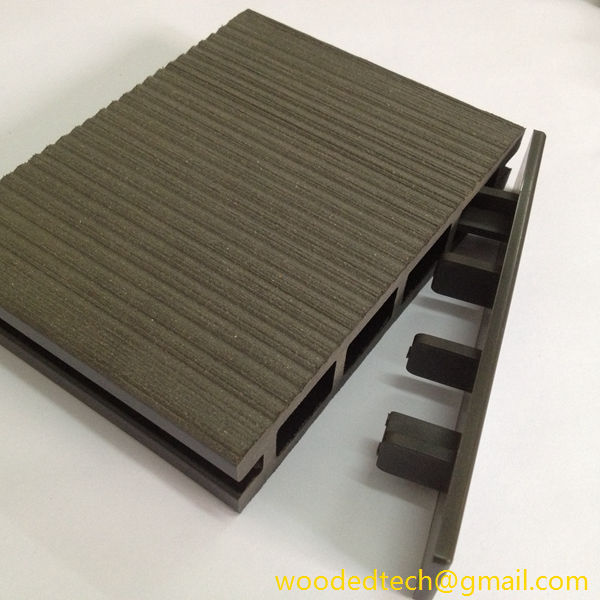

WPC decking is typically produced through an extrusion process where a mixture of wood fibers, plastic, and additives is heated and formed into boards. This process allows for a wide range of colors, textures, and finishes, making WPC decking an attractive choice for various outdoor settings. However, while the decking boards themselves are often the focus of attention, the end caps are equally important. They are designed to cover the exposed ends of the decking boards, providing a polished look and protecting the internal structure from moisture and debris.

The production of WPC end caps generally follows a similar process to that of the decking boards. The materials are blended in specific proportions to achieve the desired characteristics, such as strength, flexibility, and resistance to environmental factors. The extrusion process allows manufacturers to create end caps that perfectly match the dimensions and color of the decking boards, ensuring a cohesive appearance.

One of the primary functions of WPC decking end caps is to create a finished look. When installed, these end caps conceal the raw edges of the decking boards, which can often appear unsightly. Without proper covering, the exposed ends can detract from the overall aesthetic of the deck and may show signs of wear over time. By using end caps that are designed to match the decking, homeowners can achieve a seamless transition between the boards and the surrounding environment.

In addition to enhancing the visual appeal, WPC decking end caps serve an important safety function. The exposed ends of decking boards can be a potential hazard, especially in outdoor settings where children and pets play. Sharp edges or splintered wood can lead to injuries, making it essential to cover these areas properly. End caps provide a smooth, rounded edge that minimizes the risk of accidents, thereby enhancing the safety of the deck for all users.

Moreover, the protective qualities of end caps cannot be overlooked. WPC decking is designed to withstand various weather conditions, but the exposed ends are more vulnerable to moisture infiltration and pest intrusion. By sealing these ends with end caps, manufacturers help prevent water damage and the growth of mold or mildew. This is particularly important in regions with high humidity or frequent rain. The end caps create a barrier that helps to prolong the life of the decking boards, making them a worthwhile investment for any homeowner.

Another significant aspect of WPC decking end caps is their contribution to the overall durability of the decking system. When properly installed, these caps provide additional structural integrity to the edges of the boards. This is particularly beneficial in high-traffic areas where the edges may be subjected to wear and tear. The added protection from end caps helps maintain the integrity of the decking, ensuring that it remains functional and visually appealing for years to come.

In recent years, advancements in manufacturing technology have allowed for the production of end caps that are not only effective but also environmentally friendly. Many manufacturers are now using recycled materials in their WPC formulations, reducing waste and promoting sustainability. This trend aligns with the growing demand for eco-friendly building materials and allows homeowners to make more responsible choices when it comes to their outdoor spaces.

In conclusion, WPC decking end caps are a vital component of any decking installation. They enhance the aesthetic appeal, improve safety by covering sharp edges, and protect the decking from moisture and pests. The manufacturing process of these end caps mirrors that of the decking boards, ensuring consistency in quality and appearance. As technology continues to evolve, the production of WPC decking and its accessories will likely become even more efficient and environmentally conscious. Choosing the right end caps not only contributes to a beautiful outdoor space but also ensures a safe and durable environment for all users.