Understanding WPC Decking HS Number for Compliance and Regulatory Purposes in Construction

Wood Plastic Composites, commonly known as WPC, have gained significant popularity in the construction industry, particularly for decking applications. These materials combine the natural aesthetic of wood with the durability and low maintenance of plastic, making them an attractive choice for builders and homeowners alike. However, as with any construction material, compliance with regulatory standards is crucial. One of the essential aspects of this compliance process is the Harmonized System (HS) number assigned to WPC decking. This article delves into the significance of the HS number in the context of WPC decking production, its impact on regulatory compliance, and its implications for the construction industry.

The Harmonized System is an international nomenclature for the classification of products. It is used by customs authorities around the world to identify products when assessing duties and taxes and for gathering trade statistics. The HS number is crucial for WPC decking because it determines how the product is classified in international trade, which in turn influences regulatory requirements, tariffs, and import/export restrictions.

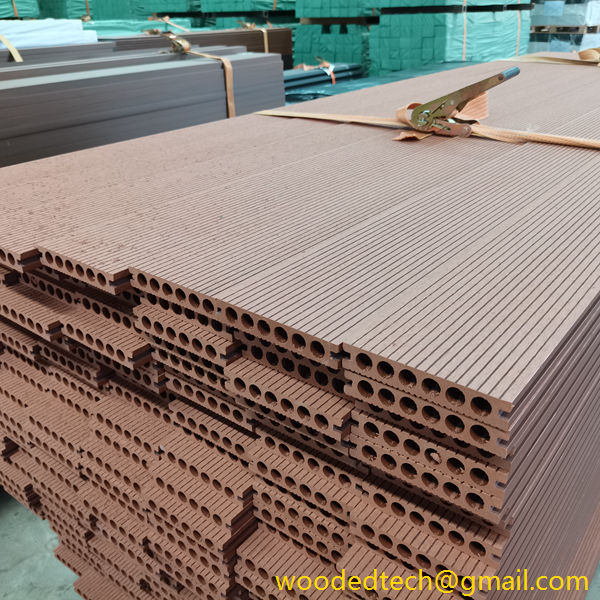

From a materials production perspective, understanding the composition of WPC is vital. WPC is typically made from a blend of wood fibers or flour and thermoplastics, such as polyethylene or polypropylene. This combination results in a composite material that boasts the advantages of both wood and plastic. The production process for WPC involves several steps, including material selection, blending, extrusion, and finishing. Each of these steps must be carefully controlled to ensure product quality and consistency.

The first step in producing WPC decking is selecting the appropriate raw materials. The choice of wood fibers is critical, as they contribute to the overall strength, durability, and aesthetic of the final product. Various types of wood can be used, including recycled wood, which further enhances the sustainability of WPC decking. The plastic component also plays a vital role, as it not only binds the wood fibers together but also provides resistance to moisture, insects, and decay.

Once the raw materials are selected, they are blended to create a uniform mixture. This blending process must be precise, as the ratio of wood to plastic will affect the mechanical properties of the WPC. After blending, the mixture is subjected to an extrusion process where it is heated and forced through a die to form the desired shape of the decking boards. This step is crucial in achieving the right dimensions and surface finish. The extruded boards are then cooled and cut to size.

After the production process, WPC decking must meet various compliance and safety standards. This is where understanding the HS number becomes essential. Different countries have specific regulations regarding the importation and use of WPC materials. The HS number helps manufacturers and importers understand what specific regulations apply to their products. For example, certain countries may have restrictions on the types of plastics that can be used or require specific certifications for environmental sustainability.

Moreover, compliance with local building codes is also influenced by the HS number. In many regions, building codes dictate the materials that can be used in construction projects based on fire resistance, structural integrity, and environmental impact. By knowing the HS number associated with their WPC decking, manufacturers can ensure that their products meet these regulations, thereby avoiding potential penalties or project delays.

Another critical aspect of WPC decking and its HS number is the documentation and reporting requirements for international trade. When exporting WPC decking, companies must provide accurate HS codes on shipping documents. Incorrect classifications can lead to customs delays, fines, or even seizure of goods. Therefore, it is imperative for manufacturers to have a clear understanding of how their products are classified within the HS framework.

In addition to regulatory compliance, the HS number can influence market competitiveness. As the demand for sustainable building materials rises, understanding the unique aspects of WPC and its classifications can provide manufacturers with a competitive edge. By marketing their products effectively and ensuring compliance with relevant regulations, companies can position themselves favorably in a growing market.

In conclusion, the understanding of the HS number for WPC decking is crucial for compliance and regulatory purposes in the construction industry. From the materials production process to international trade implications, knowledge of the HS classification helps manufacturers navigate complex regulations, ensures adherence to safety and quality standards, and enhances market competitiveness. As the construction industry continues to evolve towards more sustainable and innovative materials, staying informed about such classifications will be essential for success.