Understanding WPC Decking Joist Options for Proper Support and Installation of Your Deck

When planning to build a deck, one of the most critical components to consider is the joist system that will support the decking material. Wood Plastic Composite, or WPC, has emerged as a popular choice for decking due to its durability and low maintenance requirements. However, selecting the right joist option for WPC decking is essential for ensuring a sturdy and long-lasting installation. In this article, we will explore the various joist options available, their material production processes, and best practices for installation.

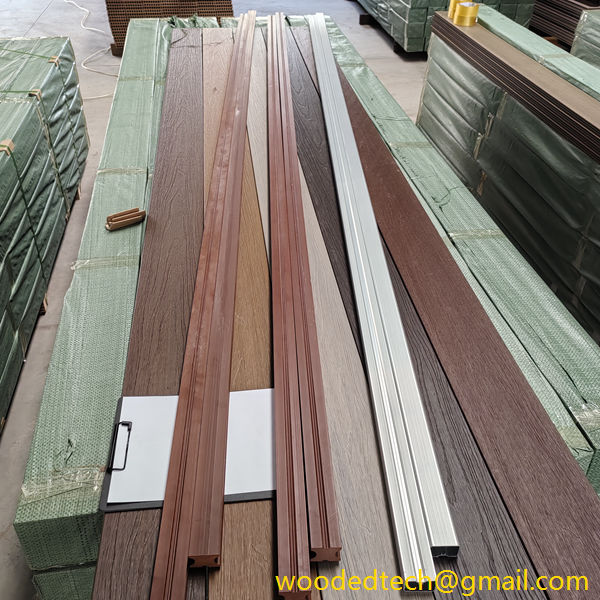

WPC decking is made from a combination of wood fibers and plastic, which provides the aesthetic appeal of natural wood while offering enhanced resistance to moisture, insects, and decay. The manufacturing process of WPC involves mixing wood fibers with thermoplastics such as polyethylene or polypropylene, often combined with additives to improve strength and longevity. This mixture is then extruded into boards that can be used for decking. The production process not only ensures a uniform and high-quality product but also allows for a variety of colors and textures to mimic traditional wood.

When it comes to supporting your WPC decking, the choice of joists is paramount. Typically, joists can be made from traditional wood, engineered wood products, or even metal materials. Each of these options has its unique characteristics, benefits, and drawbacks.

Traditional wood joists are often the most readily available and cost-effective option. They provide excellent strength and stability when properly treated and maintained. However, wood joists are susceptible to moisture damage, warping, and insect infestations, especially in environments with high humidity or exposure to rain. To mitigate these issues, it is crucial to select pressure-treated lumber or naturally resistant species like cedar or redwood, which are better suited for outdoor applications.

Engineered wood joists, such as laminated veneer lumber or I-joists, offer an alternative to traditional lumber. These products are manufactured by bonding together layers of wood fibers or veneers, resulting in a strong and lightweight material. Engineered joists are less prone to warping and shrinking than solid wood and can span greater distances without the need for additional support. Furthermore, they are often produced with a uniform size and shape, which can simplify the installation process. However, they may be more expensive than traditional wood options.

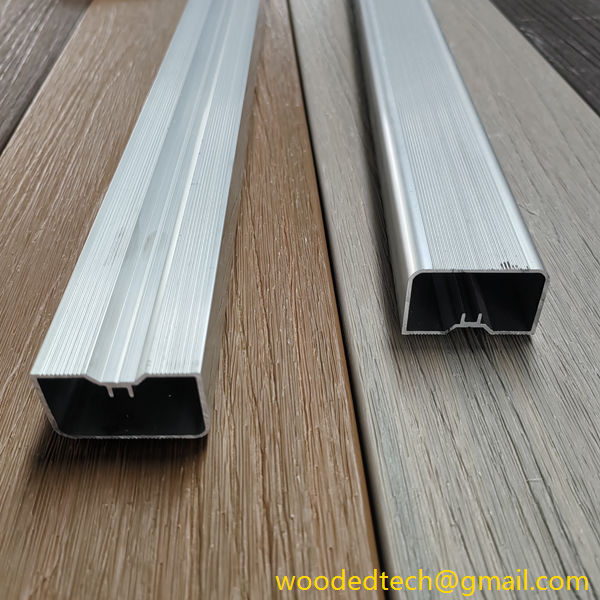

Metal joists are another option that has gained popularity in recent years. Made from materials such as steel or aluminum, metal joists offer exceptional strength and durability. They are resistant to rot, insects, and moisture, making them an ideal choice for areas with harsh weather conditions. Additionally, metal joists can provide a sleek aesthetic that complements contemporary deck designs. However, they can be more challenging to work with during installation, requiring specialized tools and skills.

Regardless of the joist material chosen, proper installation practices are essential for ensuring the longevity and stability of your WPC deck. When installing joists, it is important to follow the manufacturer’s guidelines regarding spacing and support. Typically, joists should be spaced no more than sixteen inches apart for standard decking boards, although some products may allow for wider spacing. Ensuring that the joists are level and securely anchored will help prevent sagging and movement over time.

In addition to spacing, the height and slope of the deck frame should be carefully considered. A slight slope away from the house will help facilitate drainage and prevent water pooling on the deck surface. Adequate ventilation beneath the deck is also important to reduce moisture accumulation, which can lead to mold and mildew growth.

Finally, it is essential to select the appropriate fasteners and connectors when installing WPC decking. Stainless steel or coated screws are recommended to prevent corrosion and ensure a secure attachment. Using hidden fasteners can create a clean, seamless appearance and reduce the risk of splintering or damage to the decking material.

In conclusion, understanding the various joist options available for supporting WPC decking is crucial for a successful installation. Each material has its unique production processes, benefits, and challenges that must be considered. By selecting the right joist material, adhering to proper installation practices, and ensuring adequate support and drainage, homeowners can enjoy a durable and aesthetically pleasing deck for many years to come.