Understanding WPC Decking Surface Treatment Options for Enhanced Durability and Longevity

Wood Plastic Composite, commonly known as WPC, has gained significant popularity in the construction and landscaping industries due to its unique properties that combine the advantages of both wood and plastic. WPC decking is particularly favored for outdoor applications because of its resistance to moisture, insects, and decay. However, to maximize the durability and longevity of WPC decking, it is essential to consider surface treatment options that can effectively enhance its performance.

The production process of WPC involves the mixing of wood fibers with thermoplastics, typically polyethylene or polyvinyl chloride, along with additives. This composite material exhibits characteristics that are superior to traditional wood decking, such as reduced maintenance needs and improved resilience against environmental factors. Despite these advantages, the surface of WPC decking can still be susceptible to wear and tear over time, particularly from UV exposure, stains, and physical abrasion.

One of the primary surface treatment options for WPC decking is the application of protective coatings. These coatings serve as a barrier against environmental elements that can degrade the material. There are various types of coatings available, including polyurethane, epoxy, and acrylic finishes. Each of these offers different levels of protection and aesthetic appeal. For instance, polyurethane coatings are known for their durability and resistance to water and chemicals, making them suitable for environments that experience heavy foot traffic or exposure to harsh weather conditions.

Another effective surface treatment method is the use of specialized sealants. Sealants are designed to penetrate the surface of the WPC decking and provide a protective layer that prevents moisture from seeping in. This is particularly important because moisture can lead to mold growth and structural degradation over time. Sealants not only protect against moisture but can also enhance the color and texture of the decking, providing a more appealing appearance. It is crucial to select a sealant that is compatible with the specific type of WPC being used to ensure optimal adhesion and effectiveness.

In addition to coatings and sealants, another surface treatment option is the incorporation of additives during the manufacturing process. These additives can improve the UV resistance of the WPC decking. UV inhibitors can be mixed into the composite material to reduce fading and discoloration caused by prolonged exposure to sunlight. This is particularly beneficial in regions with intense sunlight, as it helps maintain the aesthetic quality of the decking over time.

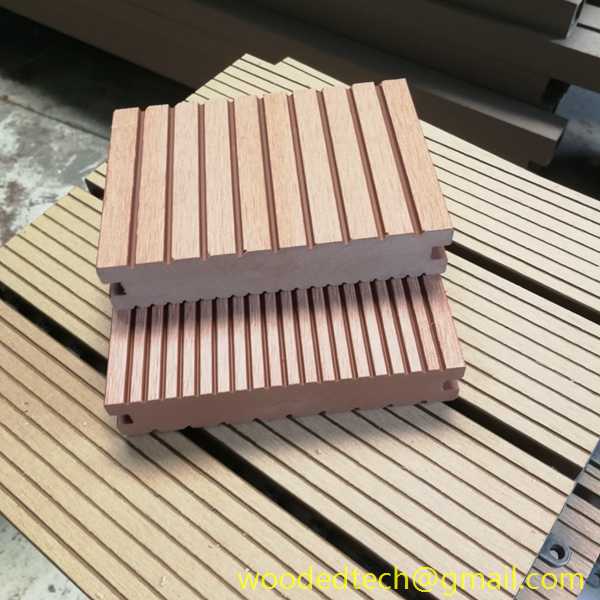

Another innovative approach is the use of extrusion techniques that create a textured surface on the WPC decking. By utilizing advanced manufacturing technologies, manufacturers can produce WPC with a slip-resistant texture that enhances safety while also improving the overall durability of the surface. This treatment not only provides a functional benefit but also contributes to the visual appeal of the decking, making it an attractive option for homeowners and builders alike.

Regular maintenance is also a critical component of ensuring the longevity of WPC decking. While the material is designed to be low maintenance, periodic cleaning and reapplication of protective treatments can significantly extend its lifespan. Routine cleaning with mild soap and water can help remove dirt and debris, preventing the buildup of substances that can cause staining or surface degradation.

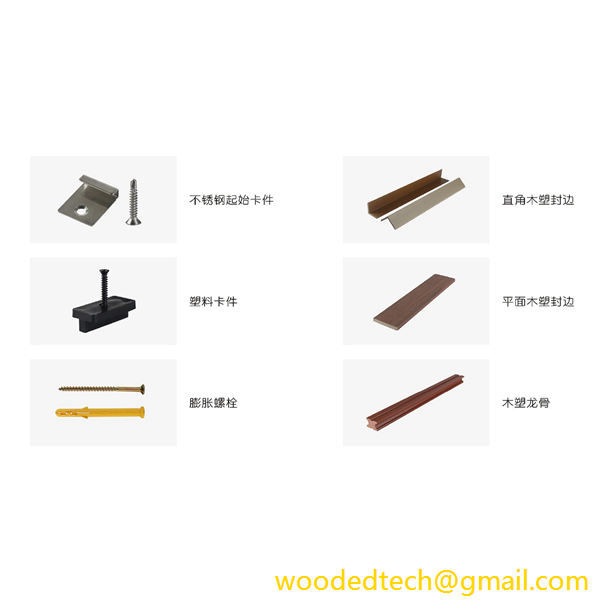

Additionally, homeowners should be aware of the importance of proper installation practices. Ensuring that the WPC decking is installed correctly can prevent issues such as warping or separation, which can compromise its durability. Utilizing appropriate fasteners and following the manufacturer’s guidelines for spacing and support can help maintain the integrity of the decking over time.

In conclusion, WPC decking offers an excellent alternative to traditional wood materials, combining the benefits of both wood and plastic for enhanced durability and low maintenance. However, to truly maximize the performance and longevity of WPC decking, it is essential to consider various surface treatment options such as protective coatings, sealants, and the incorporation of additives during production. Additionally, regular maintenance and proper installation practices play a crucial role in ensuring that WPC decking remains a reliable and attractive choice for outdoor spaces. By understanding and implementing these surface treatment strategies, consumers can enjoy their WPC decking for years to come.