Colorful charm, wpc helps creative mold design and diversified board production

In my country’s new materials industry, wpc has gradually attracted widespread attention for its unique performance and environmental advantages. In recent years, wpc has been widely used in construction, furniture, decoration and other fields. This article will focus on the application of wpc in mold design and board production, and explore how to use wpc to produce a variety of colored boards.

1. Overview of wpc

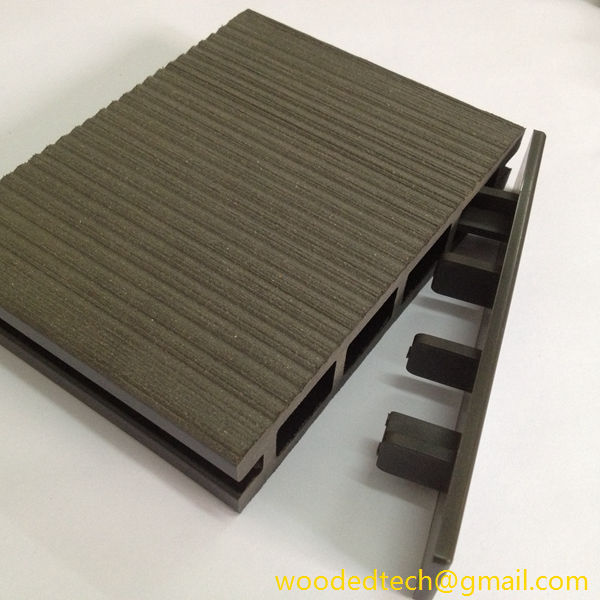

wpc (Wood-Plastic Composites, WPC) is a new type of environmentally friendly material, mainly composed of wood powder, plastic and additives and other raw materials through high temperature and high pressure compounding. wpc has the advantages of wood and plastic, such as good mechanical properties, corrosion resistance, aging resistance, waterproofness, etc., and also has the characteristics of environmental protection and renewability.

2. wpc mold design

1. Colorful mold design

wpc can design product molds of different colors according to customer needs. Designers can use rich color matching according to market demand to make wpc board have higher ornamental value and practicality. Colorful mold design not only improves the beauty of the product, but also makes wpc more advantageous in market competition.

2. Personalized mold design

WPC mold design can meet the personalized needs of customers. By adjusting the shape and texture of the mold, a Wpc board with a unique style can be produced. In addition, WPC can also be combined with other materials such as metal and glass to create more creative composite materials.

III. Wpc board production

1. Production process

Wpc board production adopts high temperature and high pressure molding process. First, the raw materials such as wood powder, plastic and additives are mixed evenly, and then sent to the high temperature and high pressure molding machine for molding. During the molding process, WPC will be fully integrated to form a board with certain strength and hardness.

2. Diversified production

Using molds of different colors, a variety of Wpc boards can be produced. The following are several common Wpc boards:

(1) Colored floor: Colored wood plastic floor has rich colors and can meet the decoration needs of different occasions.

(2) Outdoor landscape materials: WPC can produce a variety of outdoor landscape materials, such as fences, floors, seats, etc., adding a beautiful landscape to the urban landscape.

(3) Furniture materials: WPC has excellent mechanical properties and environmental performance, and can be used to make various furniture, such as beds, tables, chairs, etc.

(4) Decorative materials: WPC can produce various decorative materials, such as curtains, wallpapers, etc., providing more choices for interior decoration.

IV. Conclusion

WPC has significant advantages in mold design and plate production. Through colorful mold design and diversified production, WPC provides the market with a rich and diverse product selection. In the future, with the continuous development of WPC technology, its application in environmental protection, construction, furniture and other fields will be more extensive. Let us look forward to WPC bringing more beautiful changes to our lives.