wpc cladding is combined with metal to easily create high-quality plastic wood doors

With the development of science and technology and the improvement of people’s environmental awareness, plastic wood materials have gradually become the new favorite of home decoration. As an important part of home decoration, plastic wood doors not only have the advantages of beauty, durability and environmental protection, but also have simple processing and production processes, and can be easily customized. This article will introduce in detail how to use wpc cladding and metal materials to easily create high-quality plastic wood doors.

1. The perfect fusion of wpc cladding and metal

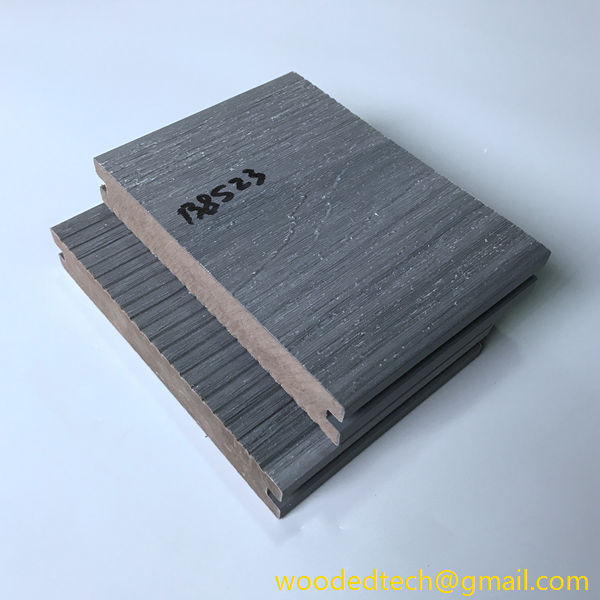

1. Features of wpc cladding

wpc cladding is a new type of environmentally friendly decorative material. It is made of wood powder, plastic and additives through high temperature and high pressure extrusion molding. wpc cladding has the following characteristics:

(1) Environmental protection: wpc cladding uses waste plastic and sawdust as raw materials, realizes the recycling of resources and reduces environmental pollution.

(2) Beautiful: wpc cladding has a smooth surface, bright color and clear texture, which can create a natural and simple home style.

(3) Durability: Wpc cladding has excellent weather resistance, wear resistance and impact resistance, and has a long service life.

(4) Easy processing: Wpc cladding can be cut, drilled, spliced and processed as needed to meet personalized customization needs.

2. Characteristics of metal materials

The application of metal materials in plastic wood doors mainly refers to materials such as aluminum alloy and stainless steel. Metal has the following characteristics:

(1) High strength: Metal materials have high strength and toughness, which can ensure the stability of plastic wood doors.

(2) Corrosion resistance: Metal materials have strong corrosion resistance and can adapt to various harsh environments.

(3) Beautiful: The surface of metal materials is smooth and the texture is strong. Combined with Wpc cladding, it is more fashionable.

2. Plastic wood door production process

1. Design plan

Before making plastic wood doors, you must first design a plan based on customer needs. When designing, you must fully consider the characteristics of Wpc cladding and metal materials to achieve a perfect fusion of the two. Here are some suggestions:

(1) Door type selection: You can choose different door types such as simple, stylish, and classical according to your home style.

(2) Color matching: The colors of wpc cladding and metal materials should be coordinated to form a unified visual effect.

(3) Size design: Design the size according to the actual conditions such as the door opening size and wall thickness.

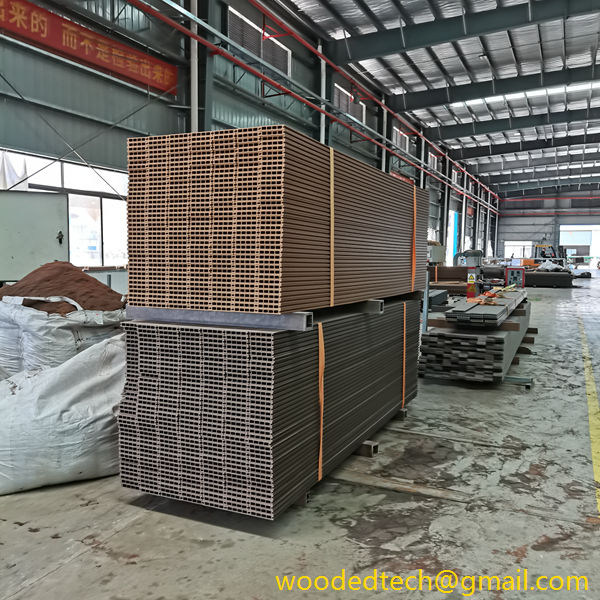

2. Material preparation

Prepare the corresponding wpc cladding and metal materials according to the design plan. When purchasing materials, pay attention to the following points:

(1) wpc cladding: Choose environmentally friendly, durable, and easy-to-process wpc cladding.

(2) Metal material: Choose high-strength, corrosion-resistant, and beautiful metal material.

3. Production process

(1) Cutting: Cut the wpc cladding and metal material according to the design size.

(2) Drilling: Drill mounting holes on the wpc cladding to connect with the metal material.

(3) Splicing: Splice the cut wpc cladding and metal materials to form a complete door leaf.

(4) Installation: Install the finished plastic wood door on the door frame and adjust the position of the door leaf so that it fits tightly with the door frame.

III. Advantages of plastic wood doors

1. Beautiful and elegant: Plastic wood doors combine the advantages of wpc cladding and metal materials, with a stylish and simple appearance and strong decorative effect.

2. Durable and environmentally friendly: Plastic wood doors have excellent weather resistance, wear resistance and impact resistance, and have a long service life. At the same time, the recycling of wpc cladding and metal materials reduces environmental pollution.

3. Easy to maintain: The surface of plastic wood doors is smooth, not easy to be contaminated with dust, and easy to clean.

4. Personalized customization: According to customer needs, it can be customized to meet the needs of different home styles.

In short, using wpc cladding and metal materials to make plastic wood doors not only has the advantages of beauty, durability, and environmental protection, but also has a simple processing and manufacturing process, which can be customized. In future home decoration, plastic wood doors will be more and more popular among consumers.