WPC (Wood Plastic Composite) external wall cladding is rapidly gaining recognition as a high-performance, sustainable solution for modern building facades. Made from a blend of wood fibers and thermoplastic materials, WPC cladding offers the appearance of natural wood while delivering the durability and low-maintenance benefits of composite materials. Its growing popularity can be attributed to several key performance advantages, including weather resistance, ease of installation, and long-term cost-effectiveness. In both residential and commercial settings, Wpc external wall cladding enhances the aesthetic appeal of buildings while protecting them from the elements. The combination of superior performance and design flexibility makes it a strong contender in the global construction market.

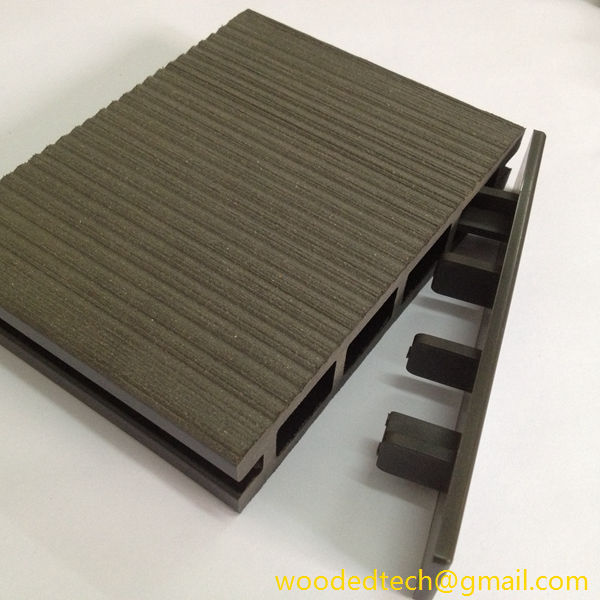

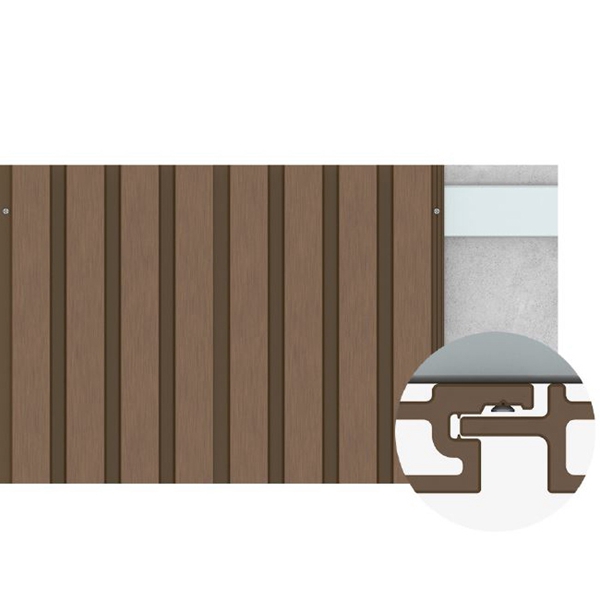

The raw materials used in Wpc external wall cladding contribute to its environmental sustainability and robustness. Typically, the product is composed of recycled wood fibers and thermoplastics, which makes it an eco-friendly choice in an industry increasingly focused on reducing carbon footprints. The advanced production process ensures consistent quality and finish, while also allowing for a variety of colors and textures that can mimic traditional wood or stone. This versatility has made WPC cladding a favorite among architects and builders looking for customizable exterior solutions that meet the aesthetic and performance demands of modern construction projects.

Market development prospects for Wpc external wall cladding are highly favorable. As the global construction industry increasingly shifts towards sustainable and low-maintenance building materials, the demand for WPC products is expected to rise. WPC cladding is particularly attractive for its ability to withstand harsh weather conditions, making it suitable for use in diverse climates. Whether it’s extreme heat, heavy rain, or freezing temperatures, Wpc external wall cladding maintains its structural integrity and appearance over time. This durability, combined with its minimal maintenance requirements, ensures long-term savings for property owners, making WPC cladding a cost-effective solution for exterior facades.

China has emerged as a leading producer of Wpc external wall cladding, leveraging its advanced manufacturing infrastructure and cost advantages to dominate the global market. Chinese manufacturers offer high-quality WPC products at competitive prices, making China a key player in the global supply chain. By analyzing the distribution of global production capacity, it is clear that China holds a significant share of the market, allowing it to meet international demand efficiently. Chinese manufacturers are known for their stringent quality control measures and continuous innovation in production processes, which ensures that their products meet the highest industry standards. As a result, buyers from around the world are increasingly sourcing WPC cladding from China due to its reliable quality and affordable pricing.

The cost-effectiveness of Chinese WPC products is further enhanced by the country’s ability to produce in large volumes, reducing production costs and ensuring a steady supply of materials. This advantage is especially beneficial for large-scale construction projects that require consistent quality and timely delivery. Additionally, Chinese manufacturers are flexible in customizing WPC cladding products to meet specific client requirements, offering a wide range of design options. As a result, international customers can rely on China as a trusted source for high-quality WPC cladding at an attractive price point, making it a preferred destination for global procurement.

The versatility of Wpc external wall cladding extends beyond its aesthetic appeal. In terms of applications, WPC cladding is used in a variety of building projects, from residential homes to commercial office buildings. It is especially popular in urban environments where building facades require both a modern look and protection against pollution, moisture, and UV exposure. In addition, WPC cladding is highly resistant to mold, rot, and insects, which further extends its lifespan compared to traditional wood materials. Its insulating properties also contribute to energy efficiency, helping to reduce heating and cooling costs in buildings. This multi-functionality has driven the demand for WPC cladding in both new construction and renovation projects.

In conclusion, Wpc external wall cladding offers excellent performance, durability, and sustainability, making it a product with broad development prospects. As global market trends shift toward eco-friendly and low-maintenance building materials, WPC cladding is well-positioned for continued growth. By analyzing the raw materials, production processes, and market applications, it is evident that WPC cladding is a superior choice for modern building exteriors. Furthermore, with China’s leadership in WPC production, offering stable quality and low production costs, we recommend that international buyers consider China as their primary source for Wpc external wall cladding. Whether for residential, commercial, or industrial projects, WPC cladding delivers a practical and aesthetic solution that meets the demands of the modern construction industry.