WPC Flooring Cost Analysis

WPC flooring, or Wood Plastic Composite flooring, has gained significant popularity in recent years due to its durability, aesthetic appeal, and affordability. As the demand for this flooring solution continues to rise, understanding the cost analysis from the perspectives of global production capacity and pricing advantages becomes essential for both manufacturers and consumers.

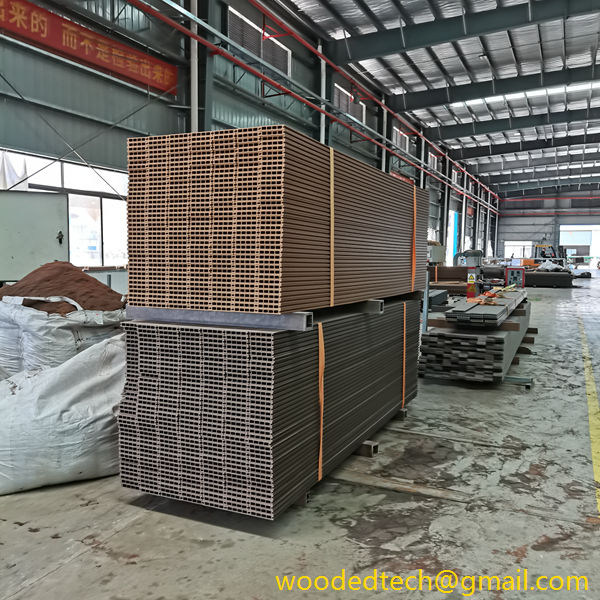

Global production capacity for WPC flooring has expanded rapidly, driven by advancements in manufacturing technologies and the increasing popularity of sustainable building materials. Major regions contributing to this growth include North America, Europe, and Asia-Pacific. Among these, Asia-Pacific stands out as a significant player in the WPC flooring market. Countries such as China and India have established extensive production facilities, leveraging their abundant raw materials and lower labor costs to dominate the manufacturing landscape. This regional advantage not only boosts production output but also enhances the overall competitiveness of WPC flooring on a global scale.

In North America, the WPC flooring market has been bolstered by a surge in renovation projects and new construction activities. The United States and Canada are key contributors to this market, with a growing number of manufacturers investing in state-of-the-art production technologies. This investment not only improves product quality but also increases production efficiency, allowing companies to meet the rising consumer demand while keeping costs manageable. The presence of established retail networks further facilitates the distribution of WPC flooring, making it easily accessible to consumers.

Europe, on the other hand, has seen a shift towards environmentally friendly products, with many consumers prioritizing sustainability in their purchasing decisions. As a result, European manufacturers have focused on developing WPC flooring solutions that incorporate recycled materials and adhere to stringent environmental regulations. While this focus on sustainability may lead to higher production costs, it can also create a unique selling point that allows manufacturers to command premium prices in the market.

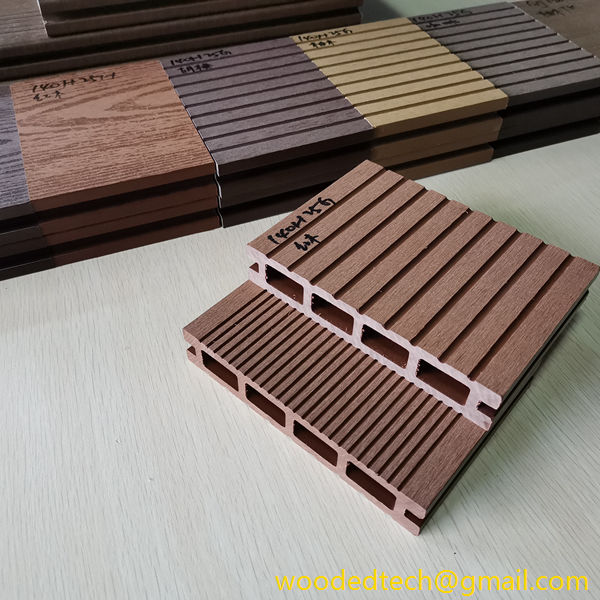

In terms of pricing advantages, WPC flooring offers a compelling alternative to traditional hardwood and laminate flooring. The cost-effectiveness of WPC flooring is primarily attributed to its composite nature, which combines wood fibers and plastic materials. This combination not only reduces production costs but also minimizes waste, as manufacturers can utilize by-products from other industries. The lower raw material costs, particularly in regions with abundant resources, play a significant role in driving down the overall price of WPC flooring.

Furthermore, the durability and low maintenance requirements of WPC flooring contribute to its long-term cost advantages. Unlike traditional hardwood, which may require regular refinishing and treatment, WPC flooring is resistant to scratches, moisture, and fading. This resilience translates to lower maintenance costs over time, making it an attractive option for homeowners and businesses alike. The initial investment in WPC flooring is often offset by the savings accrued from reduced maintenance and replacement costs.

Another factor influencing the pricing dynamics of WPC flooring is the competitive landscape among manufacturers. With a growing number of players entering the market, price competition has intensified, leading to more affordable options for consumers. Manufacturers are continually seeking ways to differentiate their products, whether through innovative designs, enhanced durability, or sustainable sourcing practices. This competition not only drives innovation within the industry but also ensures that consumers have access to a diverse range of products at varying price points.

In conclusion, the analysis of WPC flooring costs from the perspectives of global production capacity and pricing advantages reveals a complex yet fascinating landscape. The significant production capabilities in regions like Asia-Pacific, coupled with the investment in advanced manufacturing technologies in North America and the focus on sustainability in Europe, create a dynamic market environment. The inherent cost advantages of WPC flooring, driven by its composite materials and durability, further enhance its appeal to consumers. As the market continues to evolve, manufacturers must remain agile and responsive to consumer preferences while navigating the challenges of production costs and competition. Ultimately, WPC flooring stands out as a viable and cost-effective choice for those seeking stylish and durable flooring solutions.