WPC Flooring Deals and Discounts

WPC, or Wood Plastic Composite flooring, has gained significant popularity in recent years due to its unique blend of durability, aesthetics, and cost-effectiveness. As the demand for WPC flooring continues to rise, it is essential to understand the global distribution of production capacity and the price advantages that come with it. This analysis will shed light on how geographical factors and production efficiencies contribute to pricing dynamics in the WPC flooring market.

The global production capacity for WPC flooring is primarily concentrated in regions with established manufacturing infrastructures. Countries such as China, the United States, and some European nations dominate the production landscape. China, in particular, has emerged as a powerhouse in WPC manufacturing, leveraging its extensive industrial capabilities and lower labor costs. This concentration of production capacity allows for economies of scale, enabling manufacturers to reduce costs and offer competitive pricing for their products.

In addition to China, the United States has a robust WPC flooring industry, characterized by a focus on innovation and quality. American manufacturers often emphasize superior performance and eco-friendliness in their products, which can justify a higher price point. However, due to the advanced technologies and research and development investments, these manufacturers can also compete effectively in the global market by offering products that meet specific consumer needs.

The European market for WPC flooring is also growing, with countries like Germany and Sweden leading the charge. European manufacturers often prioritize sustainability and environmental compliance, which can result in higher production costs. However, they capitalize on this by marketing their products as premium options, appealing to consumers who are willing to pay extra for environmentally friendly choices.

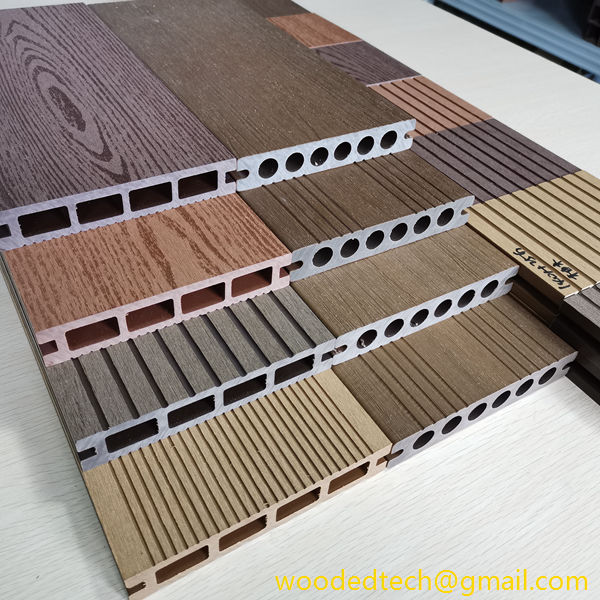

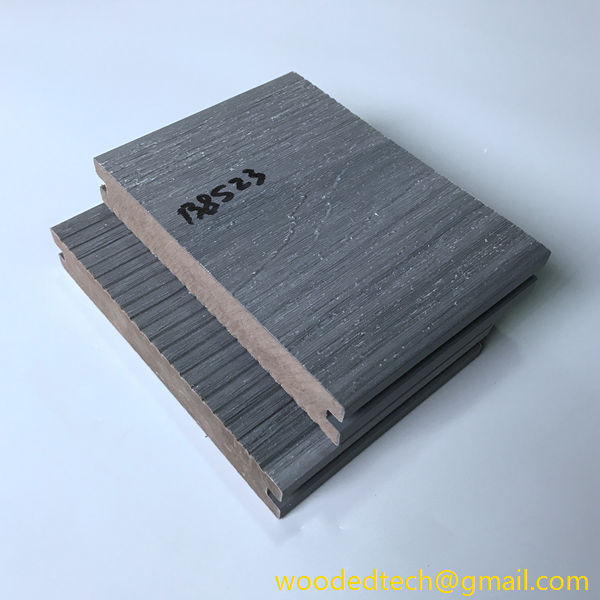

When considering the price advantages in the WPC flooring market, it is essential to recognize the impact of raw material availability and production processes. WPC flooring is made from a combination of wood fibers and thermoplastics, with the choice of materials significantly influencing the final price. Regions rich in natural resources, such as timber and plastic, can produce WPC flooring at lower costs. This is particularly evident in areas where waste wood is readily available for use in manufacturing, allowing companies to minimize raw material expenses.

Moreover, advancements in production technology play a vital role in shaping pricing strategies. The introduction of more efficient manufacturing processes has enabled companies to lower their production costs while maintaining high-quality standards. For instance, improvements in extrusion technology have enhanced the consistency and durability of WPC flooring, making it more appealing to consumers. These technological advancements not only help in reducing costs but also provide manufacturers with the ability to pass on some savings to customers, resulting in competitive pricing.

The global trade landscape also influences WPC flooring prices. Tariffs, trade agreements, and shipping costs can impact the final price of products in different regions. For example, countries that impose high tariffs on imported goods may see higher prices for WPC flooring, which could deter consumers from purchasing these products. Conversely, countries with favorable trade agreements may benefit from lower prices, making WPC flooring more accessible to a broader audience.

Seasonal demand fluctuations can also affect pricing strategies in the WPC flooring market. Certain times of the year, such as spring and summer, are peak seasons for home renovations and construction projects, leading to increased demand for flooring materials. Manufacturers often adjust their pricing strategies based on these seasonal trends, offering discounts or promotions to attract customers during slower months. This dynamic pricing approach allows manufacturers to optimize their inventory levels while remaining competitive in the market.

In conclusion, the global distribution of WPC flooring production capacity and the various price advantages that arise from it play a crucial role in shaping the market landscape. Regions with established manufacturing capabilities, access to raw materials, and innovative production technologies can deliver competitive pricing, appealing to consumers worldwide. As the market for WPC flooring continues to evolve, understanding these factors will be essential for both manufacturers and consumers alike. By recognizing the interplay between production capacity, raw material availability, technological advancements, and global trade dynamics, stakeholders can make informed decisions that align with their needs and preferences.