Wood Plastic Composite (WPC) flooring has gained immense popularity in recent years due to its unique blend of materials and the advantages it offers in both residential and commercial applications. To understand WPC flooring, it is essential to explore its meaning and the manufacturing processes involved in its production.

WPC flooring is a composite material made from a mixture of wood fibers or wood flour and thermoplastics, primarily polyvinyl chloride (PVC) or polyethylene. The wood component provides the aesthetic appeal and natural feel of traditional hardwood flooring, while the plastic component contributes to durability, moisture resistance, and ease of maintenance. This combination of materials results in a product that mimics the appearance of wood but possesses enhanced properties suitable for various environments.

The production of WPC flooring involves several key steps, beginning with the selection and preparation of raw materials. The wood fibers used in WPC flooring can come from various sources, including recycled wood products or virgin wood materials. The choice of wood type can influence the final product’s appearance, texture, and performance. The wood fibers are processed into a specific size and treated to enhance their compatibility with the plastic component.

Once the wood fibers are prepared, they are blended with the thermoplastic resins in a process known as compounding. This step is crucial as it ensures that the wood and plastic components are uniformly mixed, resulting in a homogenous material. During compounding, additives may also be included to enhance the properties of the final product. These additives can include colorants, UV stabilizers, and anti-fungal agents, which contribute to the flooring’s aesthetic appeal and performance in various environmental conditions.

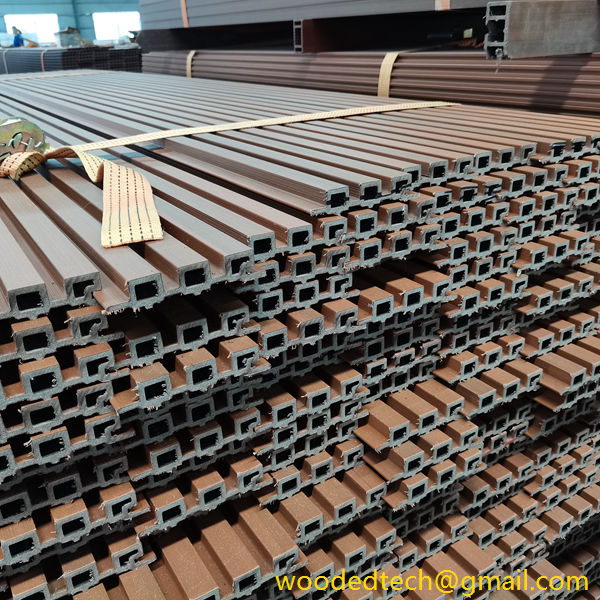

After compounding, the blended material undergoes extrusion. In this process, the mixture is heated and forced through a die to create long sheets or planks of WPC flooring. The extrusion process allows for precise control over the thickness and dimensions of the flooring, ensuring consistency in the final product. The extruded sheets are then cooled and cut into planks of desired lengths and widths.

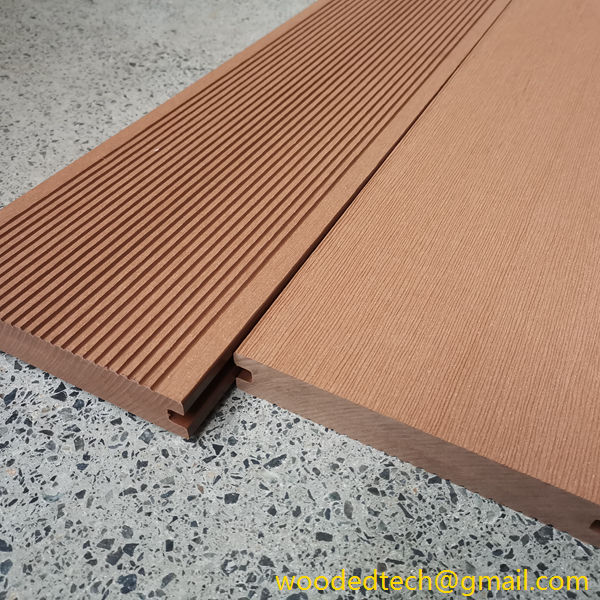

Following extrusion, the planks may undergo surface treatment to enhance their appearance and performance. This can include embossing or texturing the surface to replicate the look and feel of natural wood. Additionally, a protective coating may be applied to improve scratch resistance and UV stability, further increasing the flooring’s longevity.

Once the WPC flooring is produced, it can be used in a variety of applications. One of the most significant advantages of WPC flooring is its versatility. It is suitable for both indoor and outdoor use, making it an excellent choice for residential homes, commercial spaces, and even outdoor areas like patios and decks. The moisture-resistant properties of WPC flooring make it particularly well-suited for areas prone to humidity, such as bathrooms, kitchens, and basements.

In residential settings, WPC flooring is favored for its aesthetic appeal and ease of installation. It can be designed to mimic various wood species, allowing homeowners to achieve the look of hardwood flooring without the associated maintenance challenges. The click-lock installation system commonly used with WPC flooring makes it accessible for DIY enthusiasts, as it does not require glue or nails.

In commercial applications, WPC flooring is increasingly being used in retail spaces, offices, and hospitality environments. Its durability and resistance to wear make it an ideal choice for high-traffic areas. Additionally, WPC flooring is easy to clean and maintain, which is crucial for businesses that require a hygienic environment.

Another notable aspect of WPC flooring is its eco-friendliness. The use of recycled wood fibers in its production makes it a sustainable option compared to traditional hardwood flooring. Furthermore, many manufacturers are committed to environmentally responsible practices, ensuring that their products contribute positively to the environment.

In conclusion, WPC flooring represents a significant advancement in the flooring industry, combining the beauty of wood with the durability of plastic. The manufacturing process, from the selection of raw materials to the final product, is designed to create a flooring solution that meets the diverse needs of consumers. With its versatility, ease of installation, and eco-friendly attributes, WPC flooring is an excellent choice for both residential and commercial applications, continuing to grow in popularity as more people recognize its benefits.