WPC Flooring Thickness Explained

WPC flooring, or Wood Plastic Composite flooring, has gained significant popularity in recent years due to its durability, aesthetic appeal, and ease of maintenance. One of the most critical aspects to consider when selecting WPC flooring is its thickness. This article will explore the implications of WPC flooring thickness from the perspective of installation and maintenance.

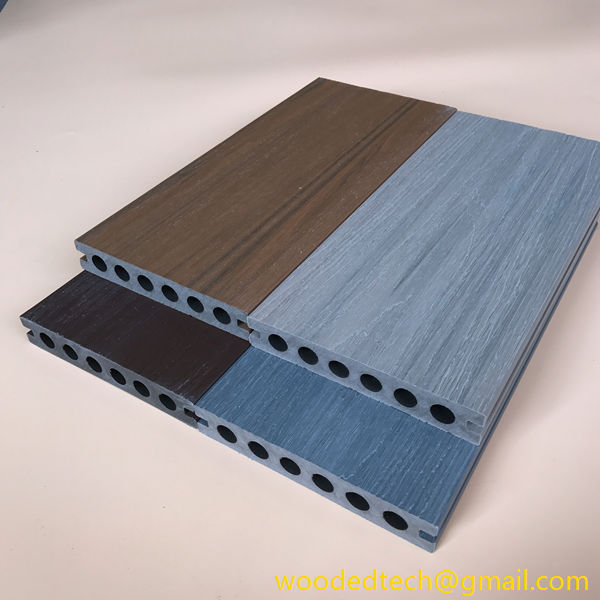

WPC flooring typically comes in various thicknesses, usually ranging from 4mm to 8mm or more. The thickness of the planks can significantly influence the overall performance of the flooring. Thicker planks are generally more robust and offer greater stability, making them suitable for high-traffic areas or installations over uneven subfloors. When choosing the thickness of WPC flooring, it is essential to consider the specific needs of your space.

From an installation standpoint, thicker WPC flooring can provide a smoother and more even surface. This can be particularly advantageous if you are installing the flooring over an existing surface that may have minor imperfections. Thicker planks can help to mask these imperfections, resulting in a more visually appealing finish. Additionally, thicker planks may also provide better sound insulation, reducing noise transmission between floors, which is especially beneficial in multi-story buildings.

It is worth noting that thicker flooring may require special consideration during installation. For instance, when installing thicker WPC flooring, it is crucial to ensure that the subfloor is adequately prepared. An uneven or improperly prepared subfloor can lead to issues such as warping or buckling over time. Therefore, it is advisable to take the time to assess the subfloor condition before installation. If necessary, make repairs or adjustments to create a level and stable base for the flooring.

In terms of maintenance, the thickness of WPC flooring can also play a role in its longevity and ease of care. Thicker planks tend to be more durable and resistant to wear and tear. This means they are less likely to show signs of damage over time, such as scratches or dents, which can be crucial in homes with pets or high foot traffic. Additionally, thicker flooring may be less susceptible to moisture damage, as it can better withstand fluctuations in humidity levels compared to thinner options.

Another aspect of maintenance to consider is the cleaning process. Thicker WPC flooring often features a more robust wear layer, which can enhance its resistance to stains and scratches. This can make the cleaning process more manageable, as spills and dirt are less likely to penetrate the surface. Regular cleaning with a damp mop and a gentle cleaner can help maintain the appearance of the flooring and extend its lifespan.

When considering WPC flooring, it is also essential to factor in the overall cost. While thicker planks may come with a higher price tag, the investment can pay off in terms of durability and reduced maintenance needs. Thicker flooring may last longer, requiring fewer replacements, which can ultimately save money in the long run.

In conclusion, the thickness of WPC flooring is a critical factor that influences both installation and maintenance. Thicker planks offer enhanced stability, durability, and resistance to wear, making them ideal for high-traffic areas and spaces with fluctuating humidity levels. However, it is essential to ensure that the subfloor is adequately prepared before installation to avoid potential issues down the line. Additionally, while the initial investment in thicker flooring may be higher, the long-term benefits can make it a wise choice for homeowners and businesses alike. Ultimately, understanding the implications of WPC flooring thickness can help you make an informed decision that meets your specific needs and preferences.