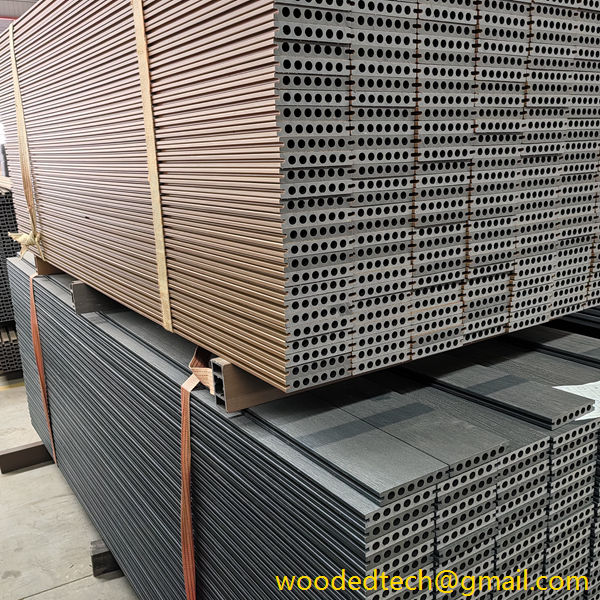

WPC Panel Dinding for Interior Walls

Wood Plastic Composite (WPC) panels have gained significant popularity in recent years, particularly for interior wall applications. The production process of WPC panels involves several key stages, each contributing to the final product’s performance, durability, and aesthetic appeal. Understanding these stages can provide insights into the advantages of using WPC panels for interior walls.

The initial stage of producing WPC panels begins with material selection. WPC is typically composed of a combination of wood fibers and thermoplastic polymers. The wood fibers can come from various sources, including recycled wood, sawdust, or wood chips, making WPC an environmentally friendly option. The thermoplastic component often includes materials such as polyethylene, polypropylene, or polyvinyl chloride. The choice of materials is crucial as it affects the mechanical properties, resistance to moisture, and overall durability of the panels.

Once the materials are chosen, the next step involves the preparation of the wood fibers and polymers. The wood fibers undergo a process of drying and grinding to achieve a uniform size and moisture content, which is essential for ensuring a consistent composite material. This preparation stage is critical because any variation in the size or moisture content of the wood fibers can lead to defects in the final product. The thermoplastic materials are also processed to ensure they are in the right form for blending with the wood fibers.

The blending stage is where the wood fibers and thermoplastics are combined to create a homogeneous mixture. This is typically achieved using high-shear mixers or extruders. In this stage, additives such as colorants, UV stabilizers, and anti-fungal agents may be introduced to enhance the performance and appearance of the WPC panels. The mixing process must be carefully controlled to ensure that the wood fibers are evenly distributed throughout the polymer matrix, which is crucial for achieving the desired strength and flexibility of the panels.

After blending, the next stage is extrusion, where the WPC mixture is heated and forced through a die to form continuous sheets or panels. This process allows for precise control over the thickness and dimensions of the panels, ensuring uniformity and consistency. The extrusion temperature and speed are critical factors that influence the properties of the final product. For instance, if the temperature is too high, it can lead to degradation of the wood fibers, while too low a temperature may result in poor bonding between the fibers and the polymer.

Following extrusion, the panels typically undergo a cooling process to solidify their shape. This is often achieved using water baths or air cooling systems. After cooling, the panels are cut to the desired sizes and may undergo additional surface treatments such as sanding or coating. These finishing processes enhance the aesthetic appeal of the panels and can improve their resistance to wear and tear.

Quality control is an essential aspect of the production process. Throughout manufacturing, various tests are conducted to ensure that the WPC panels meet industry standards for strength, moisture resistance, and dimensional stability. This may involve mechanical testing, visual inspections, and assessments of physical properties. Quality assurance measures help to ensure that the final product is reliable and suitable for interior wall applications.

One of the significant advantages of WPC panels for interior walls is their versatility. They can be manufactured in a wide range of colors, textures, and finishes, allowing for creative design possibilities. Additionally, WPC panels are lightweight, making them easy to handle and install. Their resistance to moisture and pests makes them an ideal choice for areas prone to humidity, such as bathrooms and kitchens.

Moreover, WPC panels are environmentally friendly, as they utilize recycled materials and reduce the need for traditional wood products. This aligns with the growing trend toward sustainable building materials and practices. The production process of WPC panels also generates less waste compared to conventional wood processing, further enhancing their environmental benefits.

In conclusion, the production of Wood Plastic Composite panels for interior walls involves a meticulous process that encompasses material selection, preparation, blending, extrusion, and quality control. Each stage plays a vital role in determining the final product’s performance and aesthetic qualities. With their combination of durability, versatility, and environmental sustainability, WPC panels are an excellent choice for modern interior design, appealing to both homeowners and builders alike. Their growing popularity in the market reflects a shift towards innovative materials that meet the demands of contemporary living spaces.