WPC Panel Edge Finishes for a Polished Look

Wood Plastic Composite (WPC) panels have gained significant popularity in recent years due to their unique combination of aesthetics and durability. One of the most critical aspects of WPC panel production is the edge finishing process, which is essential for achieving a polished and professional look. This article explores the various edge finishing techniques used in WPC panel manufacturing and their impact on the overall appearance and performance of the final product.

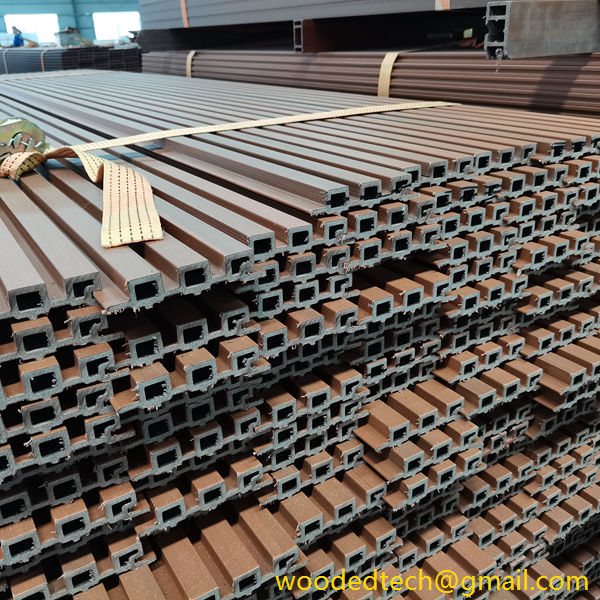

The production of WPC panels involves the blending of wood fibers and plastic materials, typically in the form of recycled polyethylene or polypropylene. This combination yields a material that possesses the natural beauty of wood while offering enhanced resistance to moisture, insects, and decay. However, the edges of these panels can often appear rough or unfinished, which detracts from their overall aesthetic appeal. Therefore, edge finishing techniques are employed to enhance the visual quality and functional performance of the panels.

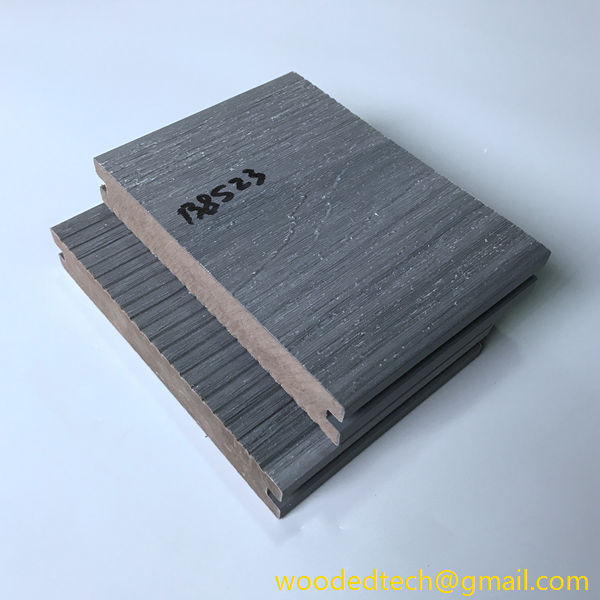

One common method of edge finishing is sanding. This process involves the use of specialized sanding equipment to smooth the edges of the panels. Sanding not only removes any rough spots or irregularities but also prepares the surface for further treatments such as painting or sealing. The grit of the sandpaper used can vary depending on the desired finish. For a more polished look, finer grits are employed to achieve a smooth and refined edge. This meticulous attention to detail during the sanding process can significantly elevate the visual appeal of the finished WPC panel.

One common method of edge finishing is sanding. This process involves the use of specialized sanding equipment to smooth the edges of the panels. Sanding not only removes any rough spots or irregularities but also prepares the surface for further treatments such as painting or sealing. The grit of the sandpaper used can vary depending on the desired finish. For a more polished look, finer grits are employed to achieve a smooth and refined edge. This meticulous attention to detail during the sanding process can significantly elevate the visual appeal of the finished WPC panel.

Another widely used technique for edge finishing is the application of a router. Routers are versatile tools that can create decorative profiles and smooth edges on WPC panels. By employing various router bits, manufacturers can produce a range of edge profiles, from simple rounded edges to more intricate designs. This customization not only enhances the aesthetic quality of the panels but also allows for greater design flexibility in architectural applications. Additionally, routered edges can provide better adhesion for subsequent coatings or laminates, further improving the durability and longevity of the panels.

In recent years, advances in technology have introduced automated edge finishing systems that streamline the production process. These systems utilize computer numerical control (CNC) machines to achieve precise edge profiles with minimal human intervention. This automation not only increases efficiency but also ensures consistent quality across large production runs. The precision offered by CNC machines allows manufacturers to create complex edge designs that were once labor-intensive and time-consuming. As a result, the final products exhibit a higher level of craftsmanship and attention to detail.

For some applications, particularly in outdoor settings, additional protective coatings may be applied to the edges of WPC panels. These coatings serve a dual purpose: they enhance the visual appeal of the edges while providing an extra layer of protection against environmental factors. Common coatings include UV-resistant finishes that prevent color fading and sealants that guard against moisture infiltration. The application of these coatings requires careful preparation and execution to ensure proper adhesion and a flawless finish. This step is crucial for maintaining the integrity and appearance of the WPC panels over time.

Another innovative approach to edge finishing involves the use of edge banding. Edge banding is a process where thin strips of material, typically made from PVC or wood veneer, are applied to the edges of WPC panels. This technique not only covers rough edges but also adds an additional design element to the panels. Edge banding can be produced in various colors and textures, allowing for customization that matches or complements the overall design scheme. This method is particularly popular in furniture manufacturing and cabinetry, where a polished look is essential.

In conclusion, the edge finishing process is a vital aspect of WPC panel production that significantly influences the final appearance and performance of the product. Techniques such as sanding, routing, CNC automation, protective coatings, and edge banding all contribute to achieving a polished and professional look. As the demand for high-quality WPC panels continues to grow, manufacturers must prioritize the development and implementation of effective edge finishing methods. By doing so, they can ensure that their products not only meet aesthetic expectations but also stand the test of time in various applications. The integration of advanced technologies and innovative techniques will further enhance the capabilities of WPC panel manufacturing, ultimately leading to a more refined and durable final product.