WPC Panel Fixing Techniques for Durability

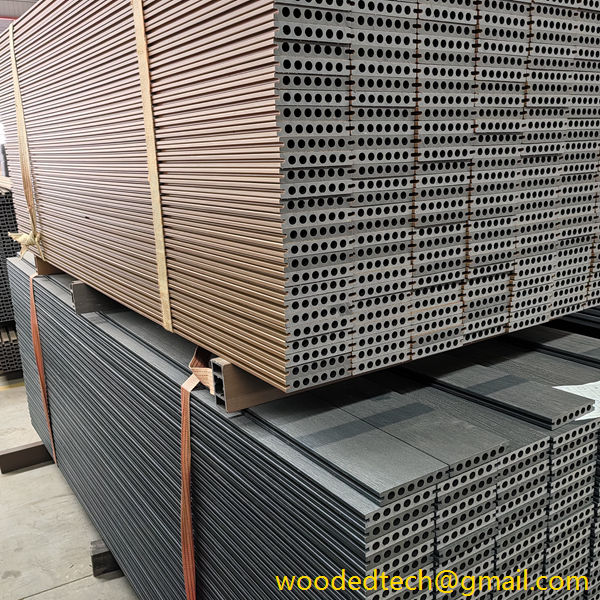

Wood Plastic Composite, commonly referred to as WPC, has gained significant traction in the construction and manufacturing industries due to its unique properties and versatility. WPC panels are widely used in various applications, including decking, railing, fencing, and even interior wall cladding. However, for these panels to perform optimally over time, it is crucial to employ proper fixing techniques. This article delves into the various fixing techniques for WPC panels, emphasizing the importance of durability and longevity in their application.

One of the primary advantages of WPC panels is their resistance to environmental factors. Unlike traditional wood, WPC does not warp, splinter, or decay, making it an ideal choice for outdoor applications. However, the effectiveness of these panels largely depends on how well they are fixed in place. Proper fixing techniques can significantly enhance the durability of WPC panels, ensuring they withstand the test of time.

First and foremost, selecting the right fasteners is critical in the installation of WPC panels. Unlike regular wood, which can be susceptible to rust and corrosion, WPC panels require fasteners made from corrosion-resistant materials such as stainless steel or coated screws. Using the appropriate fasteners not only helps in maintaining the structural integrity of the panels but also prevents any chemical reactions that could lead to premature failure. It is essential to follow the manufacturer’s recommendations regarding the type and size of fasteners to use, as this can greatly influence the longevity of the installation.

When fixing WPC panels, it is also vital to consider the spacing and alignment of the fasteners. Over-tightening screws can lead to panel cracking or deformation, while insufficient fastening can result in instability. It is recommended to follow a consistent pattern when installing the panels, ensuring uniform spacing between fasteners. This technique distributes weight evenly across the panels, reducing stress points and enhancing overall durability. Additionally, it is advisable to leave a small gap between the panels to allow for expansion and contraction due to temperature changes. This gap is crucial as it prevents buckling and warping, which can compromise the panels’ performance.

Another important aspect of fixing WPC panels is the use of support structures. For applications such as decking or fencing, a sturdy substructure is essential. The support structure should be made from durable materials that can withstand environmental conditions. When installing WPC panels, ensure that they are securely attached to the support structure using appropriate fasteners. This not only provides stability but also enhances the longevity of the installation by preventing movement that could lead to damage.

Another important aspect of fixing WPC panels is the use of support structures. For applications such as decking or fencing, a sturdy substructure is essential. The support structure should be made from durable materials that can withstand environmental conditions. When installing WPC panels, ensure that they are securely attached to the support structure using appropriate fasteners. This not only provides stability but also enhances the longevity of the installation by preventing movement that could lead to damage.

For vertical applications, such as wall cladding, it is important to consider the weight distribution of the WPC panels. Properly anchoring the panels to the wall structure is crucial to prevent sagging or detachment over time. Using wall brackets or clips specifically designed for WPC panels can provide additional support and facilitate easier installation. These accessories help maintain a clean and polished look while ensuring that the panels remain securely in place.

In addition to the physical fixing methods, it is also advisable to implement protective measures for WPC panels. While these panels are inherently resistant to moisture and insects, applying a protective sealant can further enhance their durability. Sealants provide an additional layer of protection against environmental factors such as UV rays, which can cause discoloration over time. Regular maintenance, including cleaning and reapplying sealant as needed, can greatly extend the lifespan of WPC panels.

Moreover, it is essential to consider the climate and environmental conditions where the WPC panels will be installed. In areas with high humidity or extreme temperature fluctuations, taking extra precautions in the fixing process becomes essential. For instance, using additional fasteners or opting for a more robust support structure can help mitigate the risks associated with these conditions. Understanding the specific environmental challenges allows for a tailored approach to installation, ultimately enhancing the durability of the panels.

Finally, educating installers and end-users about the best practices for fixing and maintaining WPC panels is crucial. Proper training can ensure that everyone involved in the installation process understands the importance of using the right techniques and materials. This knowledge transfer can lead to more successful installations and satisfied customers, who will benefit from the long-lasting performance of WPC panels.

In conclusion, the application of WPC panels offers numerous advantages in terms of durability and versatility. However, achieving optimal performance requires a thorough understanding of proper fixing techniques. Selecting the right fasteners, ensuring correct spacing and alignment, using appropriate support structures, and implementing protective measures are all critical components of a successful installation. By adhering to these practices, industry professionals can maximize the lifespan of WPC panels, providing customers with high-quality, durable solutions for their construction and design needs. As the market for WPC continues to grow, focusing on these aspects will be essential in meeting consumer expectations and ensuring lasting performance in various applications.