WPC Panel for Elevation Projects

Wood Plastic Composite (WPC) panels have emerged as a revolutionary material in the elevation projects of modern architecture. These panels not only provide aesthetic appeal but also offer durability and sustainability, making them a preferred choice for builders and architects alike. To understand the significance of WPC panels in elevation projects, it is essential to delve into the production processes and the unique properties that these materials possess.

The production of WPC panels involves a meticulous process that combines wood fibers and thermoplastics, typically polyethylene or polypropylene. This combination results in a composite material that retains the natural look of wood while providing the functional benefits of plastic. The production process begins with the selection of raw materials. High-quality wood fibers are sourced from recycled wood products, ensuring that the environmental impact is minimized. This aspect is particularly important in today’s eco-conscious market, where sustainability is a key concern.

Once the raw materials are collected, they undergo a thorough drying process to remove any moisture content. This step is crucial, as excessive moisture can lead to complications during the mixing and extrusion processes. After drying, the wood fibers are blended with the thermoplastic resin. This mixture is often enhanced with additives that improve the performance characteristics of the final product, such as UV resistance, color retention, and mold resistance. The precise formulation of this mixture can be adjusted based on the desired properties of the WPC panels, allowing for customization to meet specific project requirements.

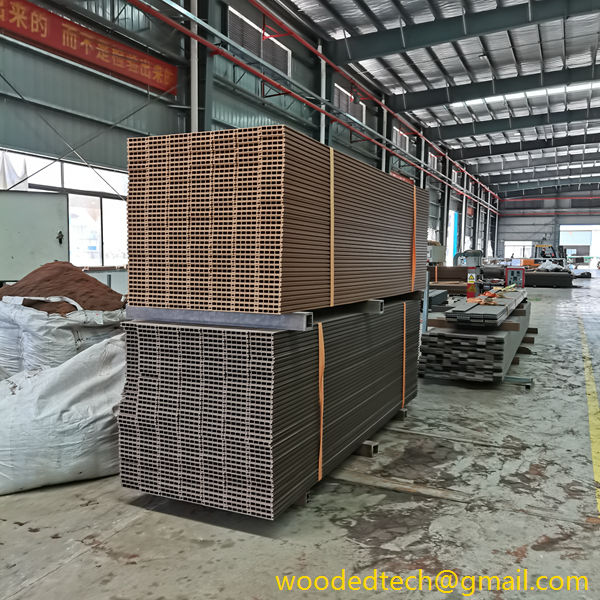

The next stage of the production process is extrusion. The blended materials are fed into an extruder, where they are subjected to high temperatures and pressures. This process melts the thermoplastic resin and allows it to bond with the wood fibers, forming a homogeneous mixture. The extruder then shapes this mixture into continuous panels, which can be cut to various lengths based on the project specifications. The extrusion process is not only efficient but also ensures that the WPC panels maintain consistent quality and performance across large production runs.

After extrusion, the panels undergo a cooling process, which solidifies the material. This step is vital as it helps to preserve the shape and dimensions of the panels. Once cooled, the panels are cut to size and can be subjected to additional treatments such as surface texturing or finishing. These treatments enhance the aesthetic appeal of the panels, making them suitable for a wide range of elevation applications. The surface can be designed to mimic natural wood grain or can be finished in various colors to complement the architectural vision of the project.

One of the standout features of WPC panels is their durability. Unlike traditional wood, which can warp, crack, or rot when exposed to moisture, WPC panels are resistant to these issues. This property makes them ideal for outdoor applications, where they are exposed to the elements. Additionally, WPC panels are resistant to pests such as termites, further extending their lifespan and reducing maintenance costs for building owners.

In elevation projects, the lightweight nature of WPC panels is another significant advantage. This characteristic simplifies the installation process, as fewer resources are required for structural support compared to heavier materials such as natural wood or stone. Moreover, the ease of handling and installation can lead to reduced labor costs and faster project completion times.

From an environmental perspective, WPC panels contribute to sustainability in multiple ways. The use of recycled materials reduces waste and conserves natural resources. Additionally, the manufacturing process of WPC panels typically consumes less energy compared to traditional wood processing methods. Furthermore, the longevity and low maintenance requirements of WPC panels mean that they have a lower environmental impact over their lifecycle.

In conclusion, WPC panels represent a significant advancement in materials technology for elevation projects. The comprehensive production process, which includes the careful selection of raw materials, precise formulation, and efficient manufacturing techniques, results in a product that meets the demands of modern architecture. With their durability, aesthetic versatility, and sustainability features, WPC panels are set to play an increasingly important role in the future of building design and construction. As architects and builders continue to seek innovative solutions that align with environmental goals, WPC panels will undoubtedly remain at the forefront of material choices for elevation projects.