WPC Panel HS Code for Customs Clearance

The global market for Wood Plastic Composites (WPC) has been expanding steadily, driven by the material’s versatility and sustainability. As industries increasingly prioritize eco-friendly solutions, WPC has emerged as a viable alternative to traditional materials. One of the key aspects of engaging in international trade of WPC is understanding the Harmonized System (HS) Code, which is essential for customs clearance. This article will delve into the global capacity distribution of WPC production and the pricing advantages that come from leveraging this innovation.

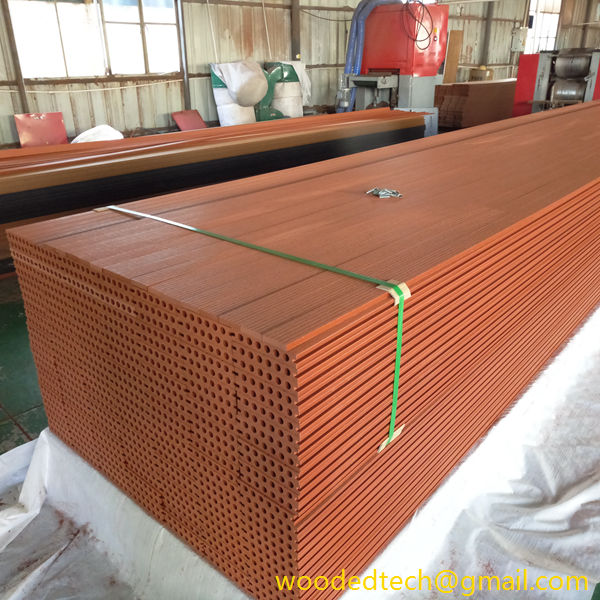

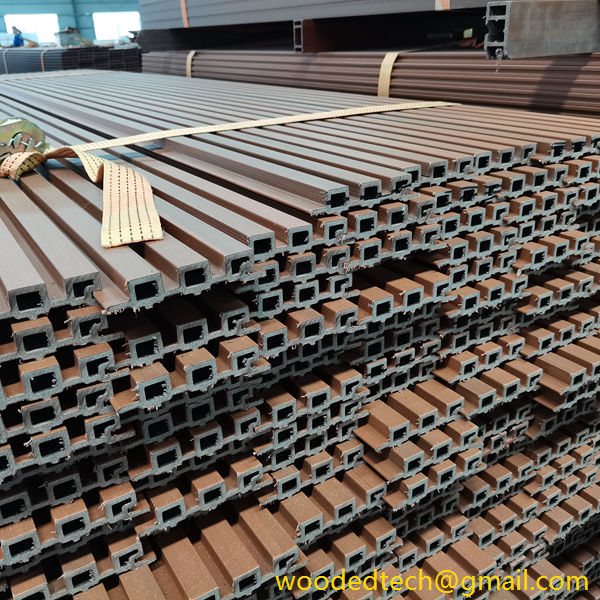

WPC panels are primarily composed of wood fibers and plastic, making them an attractive option for various applications, including construction, furniture, and automotive industries. The global production of WPC is concentrated in specific regions that have access to both raw materials and advanced manufacturing technologies. North America and Europe are leading producers, benefiting from well-established supply chains and a strong focus on research and development. Countries like the United States and Germany have invested heavily in WPC technology, resulting in a high-quality product with superior performance characteristics.

In recent years, Asia-Pacific has emerged as a significant player in the WPC market, with countries such as China, Japan, and India increasing their production capacities. The rapid urbanization and industrialization in these regions have fueled the demand for sustainable building materials, leading to increased investments in WPC manufacturing facilities. As a result, Asia-Pacific is expected to continue its growth trajectory, potentially becoming a dominant force in the global WPC market.

One of the primary advantages of WPC is its cost-effectiveness compared to traditional materials. While the initial investment in WPC manufacturing may be higher due to the technology and machinery required, the long-term benefits outweigh these costs. WPC is low-maintenance, resistant to rot, and has a longer lifespan than many conventional materials. This durability translates into lower replacement costs and reduced maintenance expenses for consumers.

Moreover, the production costs associated with WPC can vary significantly based on geographic location. Regions with abundant natural resources and lower labor costs can produce WPC panels at a fraction of the price compared to their counterparts in developed countries. For instance, manufacturers in Southeast Asia may benefit from lower raw material costs and wage expenses, allowing them to offer competitive pricing in the global market. This pricing advantage enables them to penetrate markets that may have otherwise relied on higher-priced alternatives.

When engaging in international trade of WPC panels, understanding the HS Code is crucial for customs clearance. The HS Code is a standardized numerical method of classifying traded products, allowing for easier identification and assessment by customs authorities. WPC panels are typically classified under specific codes that vary by country, but a common classification is found under the category of plastics and articles thereof. Accurately determining the correct HS Code is essential to avoid delays in customs clearance and ensure compliance with import regulations.

In addition to the HS Code, companies must also consider the various tariffs and trade agreements that may impact the cost of importing or exporting WPC panels. For instance, countries with favorable trade agreements may impose lower tariffs on WPC products, providing a significant advantage for businesses looking to expand their market reach. Understanding these dynamics can enhance a company’s competitiveness and profitability in the global WPC landscape.

As the demand for sustainable construction materials continues to rise, WPC producers must remain agile and responsive to market trends. Innovations in manufacturing processes, such as the use of recycled materials and advancements in composite technology, can further enhance the appeal of WPC panels. By focusing on sustainability and cost-effectiveness, companies can position themselves favorably in a competitive market.

In conclusion, the global distribution of WPC production capacity and the inherent pricing advantages present significant opportunities for businesses operating within this sector. As manufacturers navigate the complexities of international trade, a thorough understanding of HS Codes and customs regulations will be vital for successful market entry and expansion. The future of WPC holds great promise, with the potential for continued growth driven by a commitment to sustainability, innovation, and cost efficiency. As the industry evolves, those who adapt to these changes will be well positioned to thrive in an increasingly competitive landscape.