WPC Panel Image Gallery for Inspiration

Wood Plastic Composite (WPC) panels have gained significant popularity in recent years, particularly in construction and design sectors. They combine the natural aesthetics of wood with the durability and versatility of plastic, making them an ideal choice for various applications. This article explores the production processes involved in creating WPC panels, shedding light on the intricate steps that contribute to their remarkable characteristics.

The production of WPC panels begins with the careful selection of raw materials. The primary components include wood fibers, which can be derived from sawdust, wood shavings, or other wood byproducts, and thermoplastic polymers, such as polyethylene, polypropylene, or polyvinyl chloride. The choice of materials significantly influences the final properties of the WPC panels, including strength, flexibility, and resistance to moisture and pests.

Once the raw materials are selected, the first step is to prepare the wood fibers. This involves drying the wood to reduce its moisture content, ensuring that the fibers are suitable for blending with the plastic. The drying process is crucial, as excess moisture can lead to poor bonding between the wood and plastic, ultimately compromising the structural integrity of the panels. After drying, the wood fibers are processed into a uniform size, typically through grinding or milling, to ensure even distribution in the final composite.

The next stage involves the blending of wood fibers and thermoplastic polymers. This is achieved using an extrusion process, where the wood fibers and plastic are combined in a heated chamber. The heat melts the plastic, allowing it to coat the wood fibers thoroughly. This step is vital, as it determines the homogeneity of the WPC mixture, which directly affects the performance characteristics of the final product. The blending process can also include the addition of additives such as colorants, UV stabilizers, and flame retardants to enhance the appearance and performance of the panels.

Once the wood-plastic blend is achieved, the mixture is subjected to extrusion, where it is forced through a die to shape it into panels. The extrusion process allows for continuous production, making it a cost-effective method for creating WPC panels. The thickness and width of the panels can be adjusted by modifying the die, providing flexibility in product design. After extrusion, the panels are cooled and cut to the desired lengths. This cooling phase is critical, as it solidifies the material and ensures that it maintains its shape.

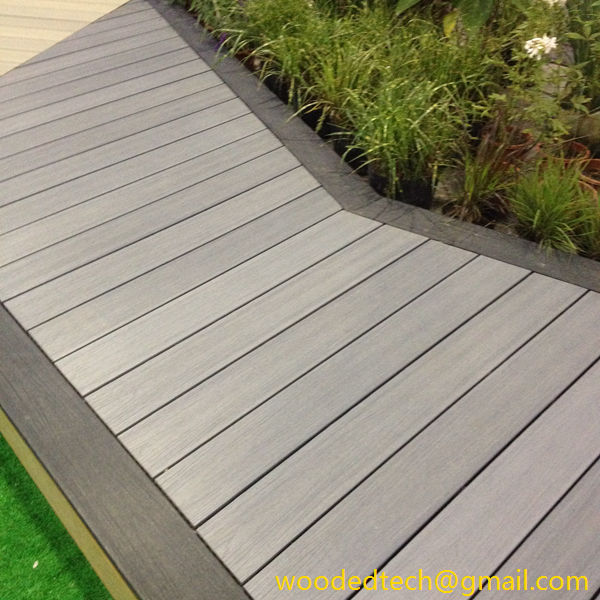

Post-extrusion processes may include surface treatments and finishing options to enhance the visual appeal and functionality of the WPC panels. These treatments can involve sanding, embossing, or applying protective coatings. Sanding provides a smooth surface, while embossing can create textures that mimic the appearance of natural wood. Protective coatings can improve resistance to scratches, stains, and UV damage, further extending the lifespan of the panels.

Quality control is an essential aspect of WPC panel production. Throughout the manufacturing process, various tests are conducted to ensure that the panels meet specific standards. These tests may include checking for dimensional accuracy, mechanical strength, and resistance to moisture and chemicals. Ensuring consistent quality is crucial for maintaining customer satisfaction and establishing a reputable brand.

The final product, WPC panels, offers numerous advantages over traditional materials. Their composite nature provides excellent durability, making them resistant to warping, splitting, and insect damage. Additionally, WPC panels are low maintenance, requiring minimal upkeep compared to natural wood. They are also environmentally friendly, as they utilize recycled materials and reduce the demand for virgin wood resources.

In conclusion, the production of WPC panels is a complex process that involves careful selection and preparation of raw materials, blending, extrusion, finishing, and rigorous quality control. This method of manufacturing not only enhances the durability and aesthetic appeal of the panels but also contributes to their growing popularity in various applications. As technology advances and more innovations emerge in the field of composite materials, WPC panels are set to play an increasingly prominent role in sustainable construction and design. Their versatility, coupled with an appealing visual finish, makes them an excellent choice for architects, designers, and homeowners seeking both functionality and style in their projects.