WPC Panel Sheet for Easy Installation

Wood Plastic Composites, commonly known as WPC, have gained significant popularity in recent years due to their excellent combination of properties, sustainability, and ease of installation. WPC panel sheets are an innovative solution that offers a wide range of benefits for both residential and commercial applications. This article explores the production process of WPC panel sheets, highlighting their advantages in terms of installation and overall performance.

The production of WPC panel sheets begins with the careful selection of raw materials. Typically, the composite is made from a blend of wood fibers and thermoplastic polymers. The wood fibers can be sourced from various types of wood, including recycled materials, which not only enhances the sustainability aspect of the product but also contributes to the reduction of waste in landfills. The thermoplastic component, often polyethylene or polypropylene, acts as a binding agent, imparting strength and flexibility to the final product.

Once the raw materials are sourced, the next step involves size reduction and blending. The wood fibers are processed into a fine powder or small particles, which are then mixed with the thermoplastic polymers in a specific ratio. This blending process is crucial as it determines the final properties of the WPC panel sheets. The mixture must be homogeneous to ensure consistent quality throughout the production process.

Once the raw materials are sourced, the next step involves size reduction and blending. The wood fibers are processed into a fine powder or small particles, which are then mixed with the thermoplastic polymers in a specific ratio. This blending process is crucial as it determines the final properties of the WPC panel sheets. The mixture must be homogeneous to ensure consistent quality throughout the production process.

After blending, the material undergoes a process called extrusion. In this stage, the combined wood and plastic mixture is fed into an extruder, which applies heat and pressure to melt the thermoplastic and allow it to bind with the wood fibers. The molten material is then forced through a die to create the desired panel sheet thickness and width. The extrusion process is highly efficient and allows for continuous production, making it a cost-effective method for manufacturing WPC panels.

Once the panels are extruded, they are cooled and cut to the required dimensions. The cooling process is essential to solidify the material and ensure stability in the final product. The cut panels may undergo additional treatments such as sanding, coating, or printing to improve their aesthetic appeal and surface finish. These finishing touches not only enhance the visual characteristics but also add protective layers that increase durability and resistance to weathering.

One of the standout features of WPC panel sheets is their ease of installation. Unlike traditional materials such as wood or metal, WPC panels are lighter in weight, making them easier to handle and transport. Their dimensional stability ensures that they do not warp or shrink over time, which can often occur with solid wood products. This stability is critical for applications in environments with varying humidity and temperature levels.

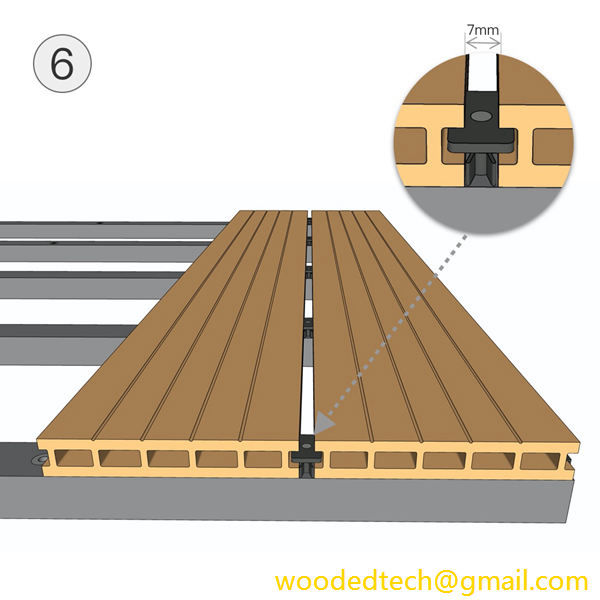

Furthermore, WPC panels are designed for straightforward installation. They can be easily cut with standard tools, allowing for quick modifications on-site without the need for specialized equipment. The panels can be fastened using conventional screws or clips, eliminating the need for complex fastening systems. This not only speeds up the installation process but also reduces labor costs, making WPC panels an economically attractive option for builders and contractors.

In addition to their ease of installation, WPC panel sheets offer a range of performance benefits. They are resistant to moisture, rot, and insects, making them ideal for outdoor applications such as decking, fencing, and siding. Their low maintenance requirements further enhance their appeal, as they do not require regular sealing or painting like traditional wood products. A simple cleaning with soap and water is usually sufficient to maintain their appearance.

WPC panels also contribute to environmental sustainability. By utilizing recycled wood fibers and thermoplastics, the production process minimizes waste and reduces the reliance on virgin materials. Additionally, WPC products are fully recyclable at the end of their life cycle, promoting a circular economy.

In conclusion, the production of WPC panel sheets involves a meticulous process that combines advanced technology with sustainable practices. The resulting panels offer a durable, lightweight, and aesthetically pleasing solution for a variety of applications. Their ease of installation and low maintenance requirements make them an ideal choice for both homeowners and builders seeking efficiency and performance. As the demand for sustainable building materials continues to grow, WPC panels are poised to play a significant role in the future of construction and design.