WPC Panel Sheet Price for Budget Planning

When considering budget planning for construction or renovation projects, one of the key materials that come into play is WPC panel sheets. WPC stands for wood-plastic composite, a versatile material that is increasingly popular in various applications due to its durability, aesthetic appeal, and eco-friendliness. Understanding the price of WPC panel sheets is essential for effective budget planning, especially for contractors, builders, and homeowners looking to optimize their expenditures.

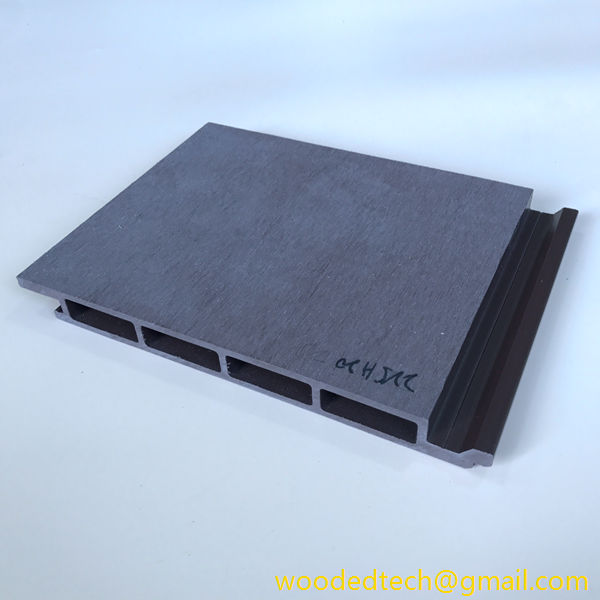

WPC panel sheets are manufactured by combining wood fibers with plastic, resulting in a composite material that offers the best of both worlds. The wood component provides a natural look and feel, while the plastic adds durability and resistance to moisture, rot, and pests. These attributes make WPC panel sheets particularly suitable for applications in areas with high humidity or exposure to the elements, such as outdoor structures, wall panels, and furniture.

Determining the price of WPC panel sheets can be influenced by several factors. One of the primary considerations is the quality of the materials used in the manufacturing process. Higher-quality wood fibers and plastics typically lead to a more durable and aesthetically pleasing product, but they also come at a higher cost. Therefore, when planning a budget, it is crucial to assess the quality required for the specific application to avoid overspending on unnecessary features.

Another factor impacting the price is the thickness and size of the WPC panel sheets. Standard sizes and thicknesses may be more affordable due to economies of scale in production. Custom sizes or thicker panels that offer additional strength and insulation properties may incur higher costs. It is essential to evaluate the project requirements carefully to determine the appropriate dimensions that balance cost with functionality.

Additionally, the supplier’s location can significantly influence the pricing of WPC panel sheets. Transportation costs can add a substantial amount to the overall price, especially if the materials need to be shipped over long distances. Therefore, sourcing materials from local suppliers can often help reduce costs and improve budget efficiency. Furthermore, establishing a good relationship with local suppliers may provide opportunities for discounts or bulk purchasing options.

Market demand also plays a crucial role in the pricing of WPC panel sheets. In periods of high demand, prices may rise as suppliers struggle to keep up, while during slower times, competition may drive prices down. Keeping an eye on market trends and understanding seasonal fluctuations can help stakeholders make informed purchasing decisions that align with their budgetary constraints.

Another important aspect to consider is the potential for price variations based on color and finish options. WPC panel sheets are available in a wide range of colors and textures that can mimic natural wood or offer unique aesthetic choices. Custom finishes may come at an additional cost, so budget planners should weigh the importance of aesthetics against overall project costs. Sometimes, opting for standard colors can lead to significant savings without compromising the project’s visual appeal.

Installation costs should also be factored into the budget when planning for WPC panel sheets. While they are often easier to install than traditional wood materials due to their lightweight nature and pre-finished surfaces, the installation process will still require skilled labor. It is advisable to obtain quotes from multiple contractors to ensure competitive pricing and to consider the learning curve if opting for DIY installation. This can be particularly beneficial for smaller projects where labor costs can significantly impact the overall budget.

Maintenance is another consideration that affects the long-term cost associated with WPC panel sheets. One of the advantages of using WPC is its low maintenance requirements compared to traditional wood. However, it is important to allocate a portion of the budget for periodic cleaning and any necessary repairs. Understanding the lifespan of the panels and the manufacturer’s recommendations for upkeep can help in planning for future expenses.

While budgeting for WPC panel sheets, it is also essential to consider potential savings in other areas. For example, because WPC is resistant to moisture and pests, it may lead to lower costs associated with repairs and replacements over time when compared to traditional materials. This long-term perspective can help justify the initial investment in WPC panel sheets and provide a clearer picture of the overall cost-effectiveness of the material.

In conclusion, when planning a budget for projects that involve WPC panel sheets, it is crucial to consider various factors that influence pricing. Quality of materials, dimensions, supplier location, market demand, color and finish options, installation costs, and long-term maintenance should all be carefully evaluated to ensure that the budget aligns with project requirements. By taking a comprehensive approach to budgeting, contractors, builders, and homeowners can make informed decisions that maximize value while minimizing expenses. Ultimately, WPC panel sheets can be an excellent investment, offering a blend of durability, versatility, and aesthetic appeal that meets the needs of modern construction and renovation projects.