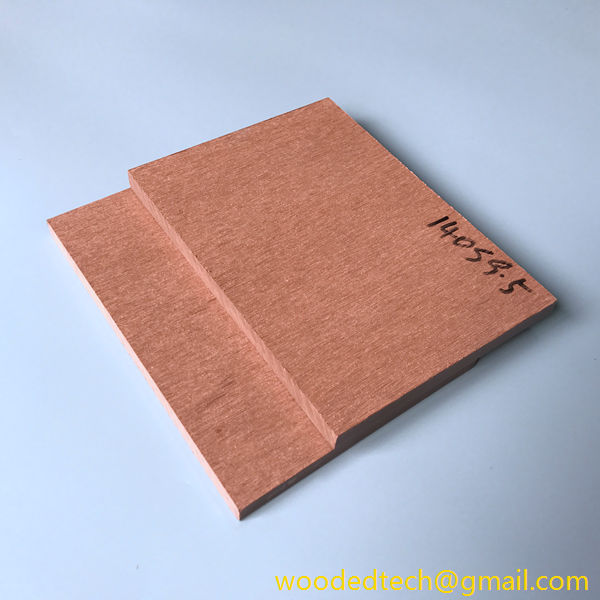

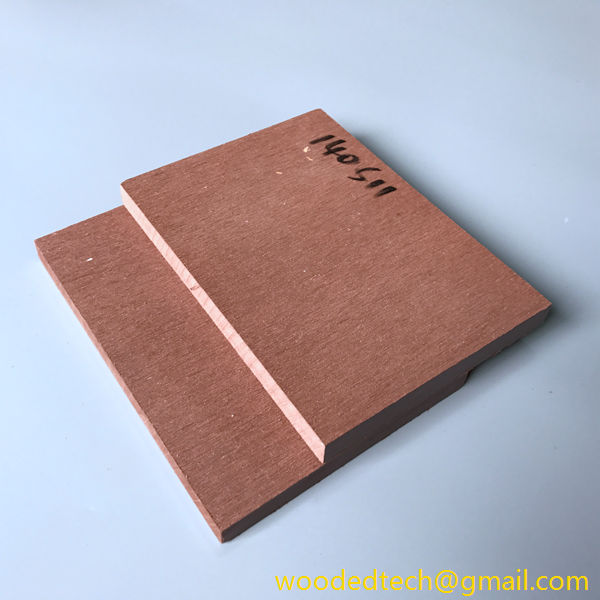

WPC Panel Width Options for Customization

WPC, or wood-plastic composite, panels have become increasingly popular in various applications due to their durability, sustainability, and aesthetic appeal. One of the significant advantages of WPC panels is the customization options available, particularly concerning their width. This article will explore the factors influencing the width options for WPC panels from a material production process perspective, emphasizing the benefits of such customization.

The production of WPC panels involves the combination of wood fibers or wood flour with thermoplastic resins. This process not only enhances the mechanical properties of the panels but also allows for a wide range of customization. The width of the panels is a critical parameter that can significantly impact their application and performance. Customization in width is essential for meeting the various demands of different industries, including construction, furniture manufacturing, and outdoor decking.

From a materials production technology standpoint, several processes can be employed to achieve the desired panel width. Extrusion is one of the most common methods used in the production of WPC panels. During the extrusion process, the raw materials are mixed and heated until they reach a molten state. This mixture is then pushed through a die, which determines the final shape and dimensions of the panel, including its width. The ability to adjust the die allows manufacturers to produce WPC panels in various widths, catering to the specific needs of their customers.

Another important aspect of WPC panel production is the formulation of the composite itself. The choice of wood fibers and thermoplastics can influence not only the width but also the overall performance characteristics of the panels. For instance, different wood fiber types may have varying densities, which can affect the thickness and width options during production. Additionally, the type of thermoplastic resin used can impact the flow characteristics during the extrusion process, allowing for further customization in width.

Furthermore, the cooling and setting process after extrusion plays a crucial role in determining the final dimensions of the panels. Once the WPC mixture is extruded, it needs to cool and solidify. The cooling rate can be controlled based on the panel width, as wider panels may require a different cooling strategy compared to narrower ones. This control over the cooling process ensures that the panels maintain their shape and do not warp, which is essential for quality assurance.

Customization options for WPC panel widths also extend to post-production processes. For instance, panels can be cut to specific widths after they have been produced. This allows manufacturers to offer a more extensive range of sizes to their customers without compromising on quality. However, it is important to note that cutting panels post-production requires precise equipment and skilled labor to ensure the edges are clean and the panels remain structurally sound.

The growing trend towards sustainable materials has also influenced the demand for customized WPC panel widths. As consumers and industries become more environmentally conscious, the need for materials that align with sustainable practices is increasing. WPC panels, made from recycled wood and plastic materials, can be tailored in width to reduce waste during production and installation. This customization not only minimizes environmental impact but also provides economic benefits by optimizing material usage.

In conclusion, the customization of WPC panel widths is a multifaceted process that involves various material production technologies and considerations. From the initial extrusion process to post-production cutting, manufacturers have the capability to meet the diverse needs of their customers. The ability to offer a range of widths not only enhances the versatility of WPC panels but also aligns with sustainable practices in material production. As industries continue to evolve, the demand for customized solutions in WPC panels will likely increase, making it an essential area for manufacturers to focus on in their production processes. This adaptability ensures that WPC panels remain a competitive choice in the market while meeting the specific requirements of various applications.