When considering the price of WPC wall panels, it is essential to understand the various factors influencing their cost, particularly from the perspective of material production processes. WPC, which stands for wood-plastic composite, is a versatile material that combines the durability of plastic with the aesthetic appeal of wood. This unique blend gives WPC wall panels numerous advantages, including resistance to moisture, insects, and decay, making them an attractive option for residential and commercial applications.

The production of WPC wall panels begins with the careful selection of raw materials. The primary components of WPC are wood fibers and thermoplastic polymers. The wood fibers can be sourced from post-industrial waste, such as sawdust or wood shavings, which contributes to the sustainability of the material. The type of wood used, its quality, and the processing methods can significantly affect the overall cost of the final product. Higher quality wood fibers may lead to a more expensive panel, but they also contribute to better aesthetics and performance.

The thermoplastics used in WPC production are typically recycled materials, such as polyethylene or polypropylene. The choice of polymer can influence the price, as some polymers are more costly than others. Additionally, the percentage of wood fiber to plastic in the composite can vary, with higher wood content often resulting in a lower cost, but potentially affecting durability and moisture resistance.

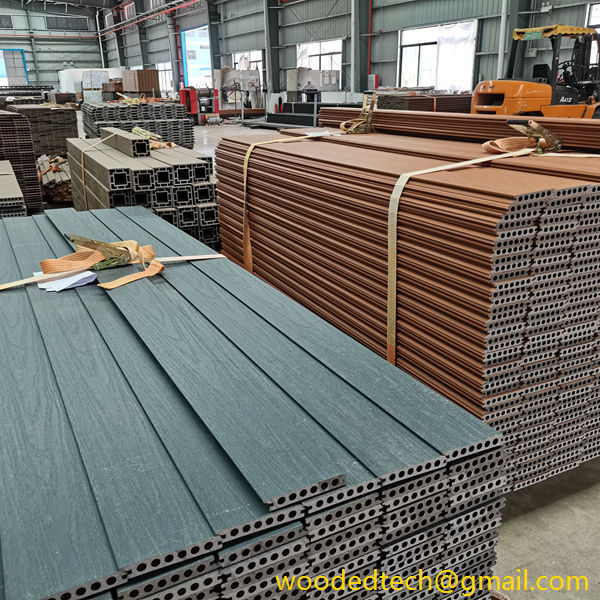

Once the raw materials are selected, the next step involves the extrusion process. During extrusion, the wood fibers and plastic are mixed and heated, allowing them to blend cohesively. The mixture is then forced through a mold to create the desired shape of the wall panel. This process requires specialized machinery and skilled operators, both of which contribute to the overall production costs. The efficiency of the extrusion process can also affect the price; a more efficient operation can lead to lower costs per unit.

After extrusion, the panels undergo additional processing, which may include cooling, cutting, and surface treatment. Surface treatment techniques can enhance the appearance of the panels and increase their resistance to environmental factors. However, these additional treatments can also add to the production costs. For example, if a manufacturer opts to add UV protection or anti-fungal agents, this will increase the price of the final product.

Quality control is another crucial aspect of the production process. Manufacturers must adhere to strict quality standards to ensure that the panels meet performance specifications. This involves regular testing of the materials and finished products, which can increase labor costs. The adherence to these quality standards can also result in fewer defects and returns, ultimately providing better value for customers.

Transportation and logistics also play a significant role in the final pricing of WPC wall panels. Depending on the location of the manufacturing facility and the distribution network, transportation costs can vary. Manufacturers located closer to their target markets may incur lower shipping costs, while those further away may need to factor in higher expenses. Additionally, the packaging of the panels for safe transit can add to the overall cost.

Market demand and supply dynamics significantly influence the pricing of WPC wall panels. As the popularity of sustainable building materials continues to rise, the demand for WPC products has increased. This heightened demand can lead to fluctuations in pricing based on market conditions. Manufacturers must remain attentive to these shifts to ensure that they remain competitive while also covering their production costs.

Another important consideration is the warranty and customer support associated with WPC wall panels. Manufacturers that offer robust warranties and customer service may charge higher prices, but this can also provide peace of mind for consumers. A strong warranty can indicate a commitment to quality, which may justify a higher initial investment for buyers.

In conclusion, the pricing of WPC wall panels is influenced by a multitude of factors related to material production processes. From the selection of raw materials to the intricacies of manufacturing and quality control, each element contributes to the final cost. Understanding these elements can help consumers make informed decisions when considering WPC wall panels for their projects. Ultimately, while price is an important factor, the value derived from durability, sustainability, and aesthetic appeal should also be weighed when making a purchasing decision.