WPC Wall Panel Specifications Explained

WPC, or Wood Plastic Composite, wall panels have emerged as a popular building material in both residential and commercial construction. Understanding the specifications and advantages of WPC wall panels can provide valuable insights for architects, builders, and homeowners. This article delves into the specifications of WPC wall panels, focusing on global production capacity and price advantages.

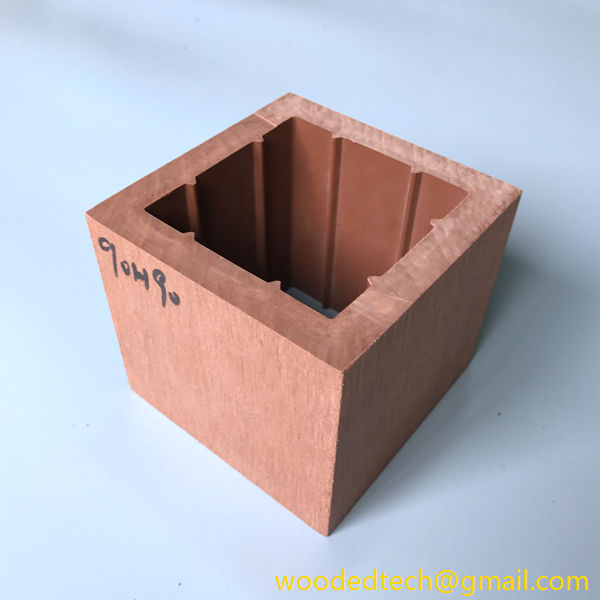

WPC wall panels are composed of a mixture of wood fibers and plastic materials, offering a unique combination of durability and aesthetic appeal. The specifications of these panels can vary significantly based on the manufacturing process, the ratio of wood to plastic, and the quality of raw materials used. Typically, WPC wall panels are available in various sizes, thicknesses, and finishes, making them versatile for different applications. Common specifications include thicknesses ranging from 8mm to 25mm, with lengths that can extend up to 4 meters or more. The surface finish can be textured, smooth, or embossed, which allows for a range of design choices that can mimic natural wood or provide a sleek modern appearance.

One of the key advantages of WPC wall panels is their resistance to moisture, pests, and decay, which makes them suitable for various climates and environments. This durability reduces the need for frequent replacements, leading to long-term cost savings. Additionally, WPC panels are often easier to install than traditional wood panels, further enhancing their appeal to builders and homeowners alike.

From a global perspective, the production capacity of WPC wall panels has seen significant growth. Major manufacturing hubs are located in regions such as North America, Europe, and Asia, with countries like China and the United States leading in production volumes. The rise in demand for eco-friendly and sustainable building materials has propelled the growth of WPC panel production. Manufacturers are increasingly investing in advanced technologies and processes to enhance the quality and performance of these products.

In terms of price advantages, WPC wall panels offer a compelling option compared to traditional building materials. The cost of raw materials for WPC production has been relatively stable, allowing manufacturers to maintain competitive pricing. Additionally, the lower maintenance costs associated with WPC panels contribute to their overall economic efficiency. Homeowners and builders can benefit from lower installation costs due to the lightweight nature of WPC panels, which reduces labor expenses.

Moreover, the global supply chain for WPC products has become more efficient, enabling manufacturers to source materials at lower costs and pass those savings on to consumers. The availability of a wide range of WPC wall panel options means that buyers can choose products that fit their budget without sacrificing quality. This price competitiveness is particularly evident in emerging markets where the demand for affordable housing solutions is rising.

Another factor contributing to the price advantage of WPC wall panels is their energy efficiency. The production process for WPC panels often involves recycled materials, which not only reduces waste but also lowers the energy consumption associated with manufacturing. This eco-friendly approach appeals to environmentally conscious consumers and aligns with global trends toward sustainable construction practices.

In conclusion, WPC wall panels represent a significant advancement in construction materials, combining durability, aesthetic versatility, and cost-effectiveness. The specifications of these panels allow for a wide range of applications, while the global production capacity continues to expand to meet increasing demand. The price advantages associated with WPC wall panels make them an attractive choice for builders and homeowners looking for sustainable and affordable building solutions. As the market for WPC products continues to evolve, it is likely that we will see further innovations in design and manufacturing processes that enhance their appeal even more. This forward momentum in production and pricing will ensure that WPC wall panels remain a competitive option in the construction industry for years to come.