WPC (Wood Plastic Composite) wall panels have gained significant attention in modern construction, primarily due to their unique combination of wood fibers and plastic. As a durable and eco-friendly alternative to traditional materials, Wpc wall panels offer excellent performance, especially in terms of moisture resistance, strength, and ease of maintenance. In this article, we’ll delve into the specifics of **Wpc wall panel thickness**, its influence on product performance, market development prospects, and why products manufactured in China stand out due to their cost-efficiency and quality.

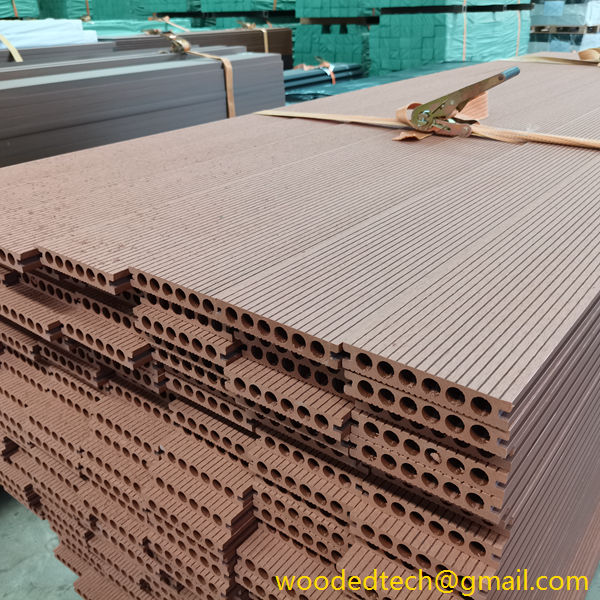

Wpc wall panels come in various thicknesses, typically ranging from 6mm to 20mm or more, depending on the application and performance requirements. The thickness plays a crucial role in determining the structural integrity, thermal insulation properties, and overall durability of the panels. For instance, thicker panels offer better insulation and strength, making them ideal for exterior walls where environmental factors like wind and moisture can significantly affect performance. On the other hand, thinner panels are more suited for interior applications where aesthetics and ease of installation are primary concerns.

The global market for Wpc wall panels is witnessing rapid growth due to the increasing demand for sustainable building materials. This growth is expected to continue in the coming years, driven by rising environmental awareness, urbanization, and the desire for long-lasting construction solutions. In terms of **Wpc wall panel thickness**, the trend is leaning towards more customized solutions, where manufacturers offer varying thicknesses based on the specific needs of different regions and building requirements. In colder climates, for example, thicker panels are favored for their superior insulation, while in warmer regions, thinner panels may suffice.

In addition to performance benefits, the raw materials used in Wpc wall panels contribute significantly to their advantages. The combination of wood fibers and plastic ensures that these panels are resistant to rotting, warping, and insect damage, which is common with traditional wood panels. Moreover, the production process of WPC panels is environmentally friendly, as it often involves the use of recycled plastics and wood waste, reducing the overall environmental footprint. As a result, **Wpc wall panel thickness** directly correlates with the panel’s durability and resistance to external elements, further highlighting their suitability for various construction projects.

When examining the global production capacity of Wpc wall panels, China emerges as a dominant player in the market. The country’s ability to mass-produce high-quality WPC products at a lower cost gives it a competitive edge. The production of **Wpc wall panels in China** benefits from advanced manufacturing technologies, efficient supply chains, and access to high-quality raw materials. Consequently, products manufactured in China are not only cost-effective but also meet international quality standards, making them highly attractive for buyers worldwide.

Moreover, the production costs of WPC panels in China are significantly lower than in other regions. This is due to the lower labor costs, access to raw materials, and economies of scale achieved by Chinese manufacturers. Despite the lower production costs, **Wpc wall panels produced in China** maintain stable and excellent quality, thanks to stringent quality control measures and the use of advanced production processes. This combination of high quality and low cost makes Chinese-manufactured WPC panels a preferred choice for many international buyers.

Looking at the market development prospects, **Wpc wall panel thickness** will continue to play a pivotal role in influencing consumer decisions. As more industries adopt green building practices and sustainable materials, the demand for WPC panels is expected to rise. Their excellent performance in terms of moisture resistance, thermal insulation, and durability makes them a go-to solution for both residential and commercial construction projects. Furthermore, the flexibility in thickness options allows architects and builders to tailor the panels to specific project needs, making WPC panels a versatile solution for various applications.

In conclusion, Wpc wall panels have a promising future due to their outstanding performance characteristics, eco-friendliness, and cost-effectiveness. When combined with the right **Wpc wall panel thickness**, these products offer unmatched durability and versatility, making them suitable for a wide range of construction projects. The global production landscape, particularly in China, further strengthens the case for WPC panels, as Chinese manufacturers consistently deliver high-quality products at competitive prices. For buyers looking for long-lasting, eco-friendly, and cost-effective solutions, purchasing **Wpc wall panels from China** is a highly recommended option.