WPC Wall Paneling Techniques for DIYers

Wood Plastic Composite (WPC) wall paneling has gained significant popularity among DIY enthusiasts due to its aesthetic appeal, durability, and ease of installation. Understanding the production techniques behind WPC can enhance the DIY experience, enabling individuals to make informed choices about materials and methods. This article will explore the various techniques involved in producing WPC wall paneling, providing valuable insights for DIYers.

WPC is a composite material made from a blend of wood fibers and plastic polymers. The production process typically begins with the careful selection of raw materials. The wood component is usually sourced from recycled wood or wood by-products, such as sawdust and wood shavings. This not only makes WPC an environmentally friendly option but also minimizes waste. The plastic component is often derived from recycled plastics, such as polyethylene or polypropylene. The combination of these materials results in a product that retains the natural aesthetic of wood while offering the durability of plastic.

The first step in the WPC production process is the blending of wood fibers and plastic. This can be accomplished through various methods, including extrusion and injection molding. In the extrusion process, the wood and plastic components are fed into an extruder, where they are heated and mixed until a homogeneous material is formed. This mixture is then forced through a die to create continuous sheets or profiles, which can be cut to the desired length for wall paneling. This method allows for uniformity in thickness and texture, making it ideal for producing wall panels.

Injection molding, on the other hand, involves injecting the blended material into a mold. This technique enables the creation of intricate shapes and designs that can enhance the visual appeal of WPC wall panels. While extrusion is more common for producing long panels, injection molding is often used for making smaller components or decorative elements.

Injection molding, on the other hand, involves injecting the blended material into a mold. This technique enables the creation of intricate shapes and designs that can enhance the visual appeal of WPC wall panels. While extrusion is more common for producing long panels, injection molding is often used for making smaller components or decorative elements.

After the initial production phase, the surface treatment of WPC wall panels is crucial for enhancing their aesthetic qualities and performance. Surface finishing techniques can include sanding, embossing, or applying a protective coating. Sanding helps to achieve a smooth finish, eliminating any rough edges or imperfections. Embossing, which involves pressing a pattern into the surface of the panel, can create a wood-like texture that further enhances the visual appeal. Additionally, applying a protective coating can improve resistance to moisture, UV light, and scratches, ensuring the longevity of the panels in various environments.

Coloration is another important aspect of WPC wall panel production. DIYers can choose from a range of colors and finishes to match their design preferences. The coloration process can involve the addition of pigments during the blending stage or the application of stains and paints after the panels have been produced. This flexibility allows for a broad spectrum of design possibilities, enabling DIYers to customize their wall panels to suit their unique styles.

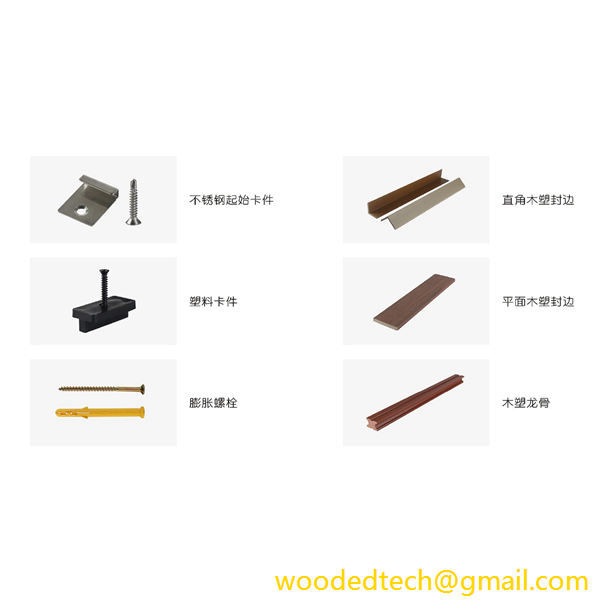

Once the WPC wall panels are produced and finished, the installation process becomes the next focus for DIYers. The lightweight nature of WPC panels makes them easy to handle and install, even for those without extensive construction experience. Various fastening methods can be employed, including adhesive, screws, or clips. Adhesive applications provide a seamless look, while screws and clips offer additional security and stability.

Moreover, one of the significant advantages of WPC wall paneling is its resistance to moisture and pests. Unlike traditional wood, which can warp or rot when exposed to moisture, WPC is impervious to these issues. This makes it an excellent choice for installation in areas prone to humidity, such as bathrooms or kitchens. Additionally, WPC does not attract insects, eliminating concerns about termites or other pests that can damage wooden structures.

For DIYers looking to achieve a professional finish, it is essential to follow proper installation techniques. Pre-measuring the space, ensuring level surfaces, and maintaining consistent spacing between panels can contribute to a polished appearance. It is also advisable to acclimate the panels to the environment before installation to minimize expansion or contraction due to temperature changes.

In conclusion, the production techniques behind WPC wall paneling play a significant role in its appeal as a DIY option. From the careful selection of raw materials to the blending, molding, and finishing processes, each step contributes to creating a versatile and durable product. With its ease of installation and customization options, WPC wall paneling offers an accessible solution for DIYers looking to enhance their spaces with a modern touch. Understanding these techniques not only empowers individuals to make informed choices but also inspires creativity in their home improvement projects.