A Step-by-Step Guide to WPC Decking Installation Video for DIY Enthusiasts

As the interest in outdoor living spaces continues to grow, many homeowners are turning to Wood Plastic Composite decking, commonly known as WPC decking, for their patio, deck, or garden spaces. This material combines the aesthetic appeal of wood with the durability and low maintenance of plastic, making it an attractive option for DIY enthusiasts. This guide will present a comprehensive overview of WPC decking installation, focusing on the material production processes that contribute to its unique properties.

To begin with, it is essential to understand the composition of WPC decking. WPC is manufactured by combining wood fibers with thermoplastic polymers. The wood fibers provide a natural appearance and texture, while the polymers enhance durability and resistance to weathering. The production process starts with the selection of raw materials. Manufacturers typically use recycled wood and thermoplastics, which makes WPC decking an environmentally friendly option. The wood is processed into fine fibers, and the plastics are usually sourced from post-consumer materials, helping to reduce waste.

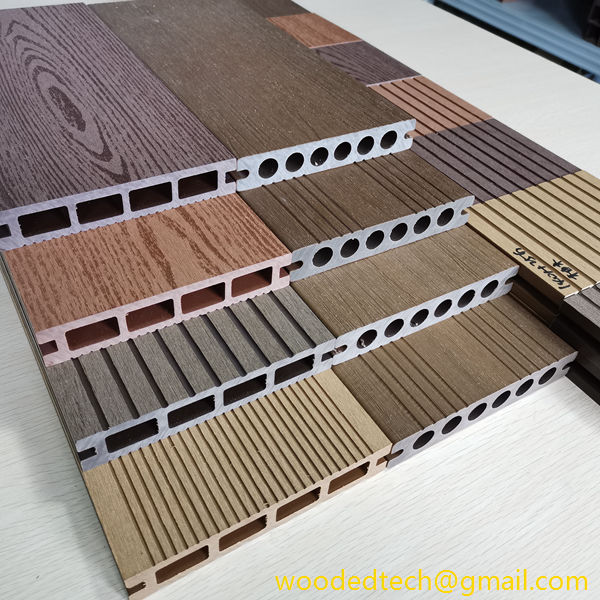

Once the raw materials are selected, the next step involves blending them. The wood fibers and plastics are combined in a specific ratio to achieve the desired properties of the decking material. This mixing process is crucial as it ensures uniform distribution of the wood and plastic components, which ultimately affects the performance and strength of the final product. During this stage, additives such as colorants, UV stabilizers, and anti-fungal agents are often included to enhance the appearance and longevity of the decking.

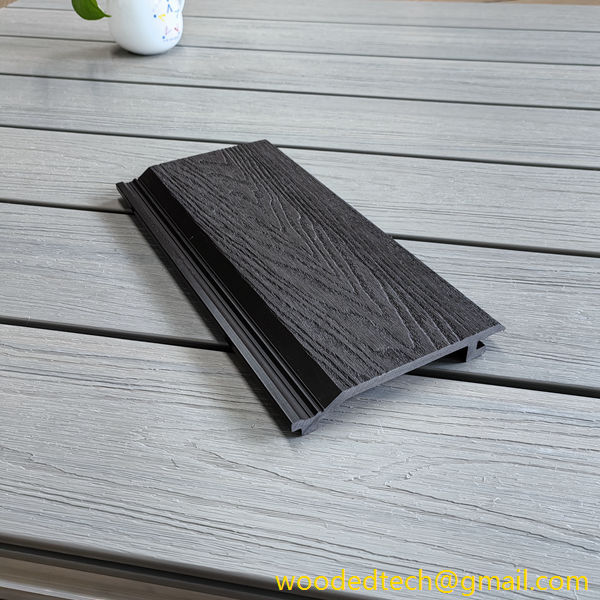

Following the blending process, the mixture is subjected to a process known as extrusion. In this phase, the blended material is heated and forced through a mold to create the desired shape of the decking boards. The extrusion process allows for the production of boards in various profiles and sizes, catering to different design preferences and installation requirements. After the boards are extruded, they undergo cooling to solidify their shape and ensure structural integrity.

Once the WPC decking boards have cooled, they are trimmed and inspected for quality. This quality control step is vital as it ensures that only the best products are delivered to consumers. Manufacturers may conduct several tests to check for consistency in color, texture, and overall strength. The final products are then packaged and prepared for distribution.

Now that we have an understanding of the production process, we can move on to the installation of WPC decking. As a DIY enthusiast, having the right tools and materials is crucial for a successful project. You will need WPC decking boards, screws or hidden fasteners, a saw for cutting the boards, a drill, and a measuring tape. Additionally, ensure you have safety gear, including gloves and goggles.

Before beginning the installation, it is important to prepare the area where the decking will be laid. This includes clearing any debris, leveling the ground, and ensuring proper drainage to prevent water pooling under the deck. A solid foundation is key to the longevity of your decking.

Once the area is prepared, the next step is to lay the framework. This typically involves installing joists that will support the decking boards. The spacing of the joists is crucial and should adhere to the manufacturer’s recommendations to ensure adequate support for the boards. Once the joists are in place, it is time to start laying the WPC decking boards.

When laying the boards, begin at one end and work your way to the other. If using screws, pre-drill holes to prevent splitting the boards. If using hidden fasteners, follow the manufacturer’s instructions for installation. It is important to leave a small gap between the boards to allow for expansion and contraction, which is a common characteristic of WPC materials.

As you continue to install the boards, periodically check for levelness and alignment to ensure a professional finish. Once all the boards are in place, the final step is to clean the surface and remove any debris. WPC decking requires minimal maintenance, but regular cleaning with soap and water can help maintain its appearance over time.

In conclusion, WPC decking is an excellent choice for DIY enthusiasts looking to enhance their outdoor living spaces. Understanding the production process sheds light on the material’s durability and appeal. With the right tools and preparation, installing WPC decking can be a rewarding project that adds value and enjoyment to your home. By following the steps outlined in this guide, you can successfully install WPC decking and create a beautiful outdoor area that you will enjoy for years to come.