Learn About WPC Cladding Weight for Structural Considerations

When considering the use of Wood Plastic Composite (WPC) cladding in construction, one of the critical factors to take into account is its weight. Understanding the weight of WPC cladding is essential for structural considerations, as it can significantly influence the design, installation, and overall performance of a building. WPC is an innovative material that combines the natural aesthetics of wood with the durability and low maintenance of plastic. This combination offers numerous advantages, but the weight of the material can have implications for structural integrity and building efficiency.

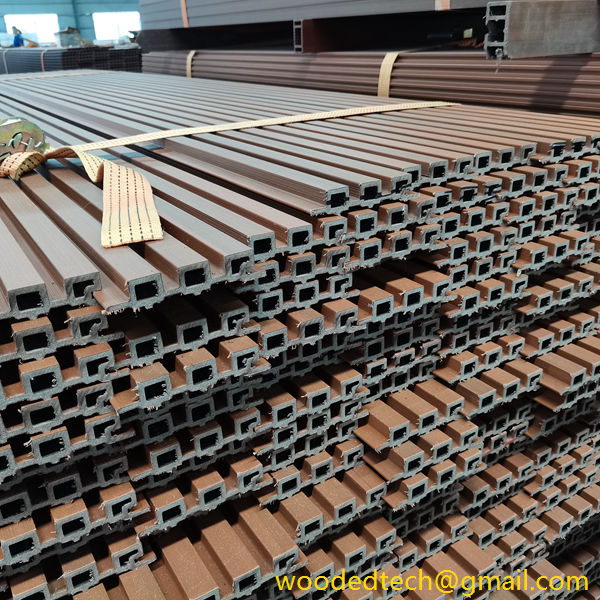

WPC cladding typically weighs less than traditional wood or solid plastic alternatives, which can facilitate easier handling and installation. This reduced weight is particularly beneficial for projects where labor costs are a concern, as lighter materials often require less manpower for transportation and installation. Furthermore, the lower weight of WPC cladding can lead to decreased load on structural elements such as walls, beams, and foundations. This aspect is particularly crucial in multi-story buildings or structures with specific load-bearing requirements.

From a structural engineering perspective, the weight of building materials is a vital consideration. Engineers must ensure that the materials used can adequately support the loads they will encounter, including dead loads, live loads, and environmental loads such as wind and snow. The use of WPC cladding can lessen the overall weight of a structure, potentially allowing for more flexible design options and reducing the need for extensive reinforcement. This can lead to cost savings not only in terms of material expenses but also in labor and construction time.

Moreover, the weight of WPC cladding can influence the overall energy efficiency of a building. Heavier materials tend to have better thermal mass properties, which can contribute to energy efficiency by helping to regulate indoor temperatures. However, WPC cladding, with its lighter weight, can still offer significant thermal insulation benefits, especially when used in conjunction with other insulating materials. The combination of a lightweight cladding system and appropriate insulation can create a balanced approach to energy efficiency and structural integrity.

Another important aspect of WPC cladding weight is its impact on transportation logistics. The reduced weight can lead to lower transportation costs, making it an appealing option for builders and contractors. Lighter materials can be shipped in greater quantities, reducing the number of trips required to transport materials to the construction site. This not only helps in managing costs but also contributes to a more sustainable construction process by minimizing fuel consumption and emissions associated with transportation.

In terms of performance, WPC cladding is designed to withstand various environmental conditions, including moisture, UV exposure, and temperature fluctuations. The weight of WPC contributes to its performance characteristics, as a lighter material may be less prone to issues such as warping or cracking under stress. Additionally, the composite nature of WPC allows for enhanced durability compared to traditional wood. This durability means that WPC cladding can maintain its structural integrity over time, providing long-lasting performance without the need for frequent repairs or replacements.

When assessing the weight of WPC cladding, it is also essential to consider the specific application and context of use. Different projects may have varying requirements regarding weight, strength, and durability. For example, residential buildings may prioritize aesthetic appeal and ease of installation, while commercial structures may focus more on long-term performance and cost-effectiveness. Understanding these project-specific needs can guide the selection of the appropriate type and weight of WPC cladding.

In conclusion, the weight of WPC cladding plays a significant role in structural considerations for construction projects. Its lighter weight can lead to easier handling, reduced labor costs, and decreased load on structural systems. Additionally, WPC cladding offers advantages in terms of energy efficiency, transportation logistics, and long-term performance. As architects and builders continue to seek innovative materials that balance aesthetics, durability, and sustainability, WPC cladding stands out as a versatile option that meets diverse structural requirements while providing the benefits of modern material technology. Understanding the implications of weight in this context is crucial for making informed decisions that enhance the overall success of construction projects.